Anti-loose connection pair

A connection pair and anti-loosening technology, which is applied in the direction of connection components, threaded fasteners, screws, etc., can solve the problems of bolt connection pair loosening and falling off, and achieve the effect of not being easy to loosen, increasing friction, and ensuring overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

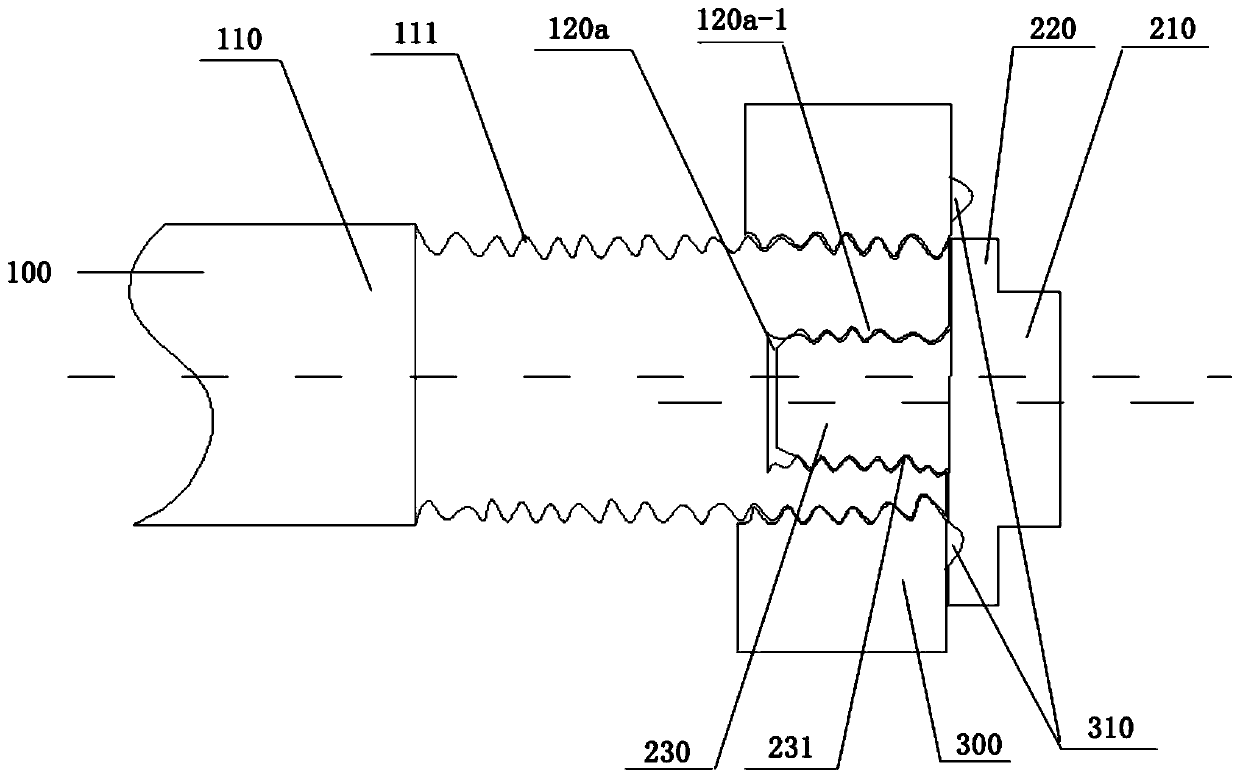

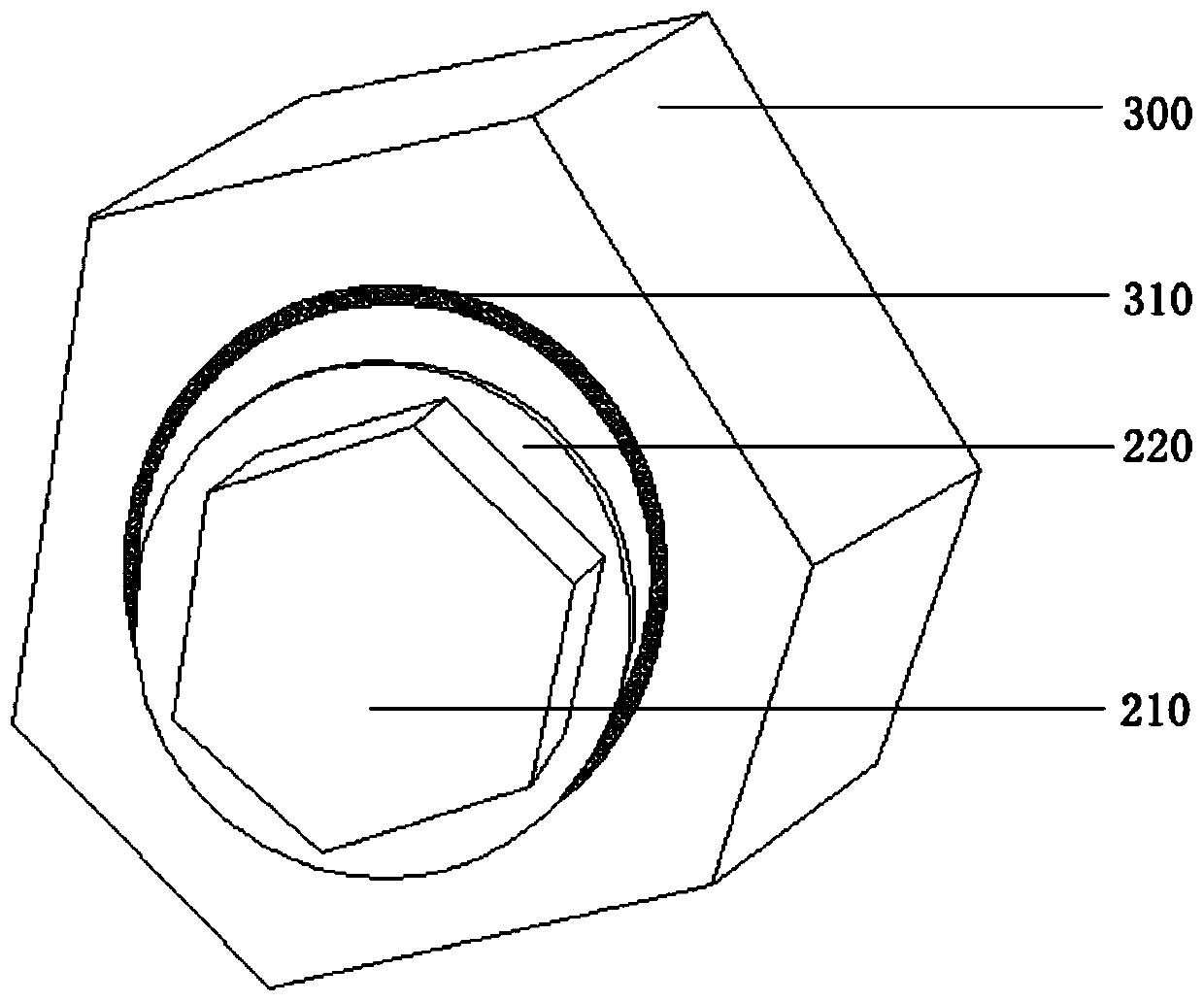

[0050] Such as Figure 1-4 As shown, an anti-loosening connection pair includes an eccentric bolt (100), a locking bolt (200) and a backstop (300), the backstop (300) acts as a thrust washer, and the eccentric bolt (100 ) includes a screw part (110) and an inner nut (120a), the backwash washer is sleeved on the screw part (110), and the inner nut (120a) is set at one end of the screw part (110) In the groove, the central axis of the screw part (110) and the central axis of the inner nut (120a) are not on the same straight line. The locking bolt (200) is coaxially provided with a flange part I (210), a boss part I (220) and a bolt part (230) connected in sequence, and the bolt part (230) is connected to the inner nut (120a ) threaded connection.

[0051] The outer wall of the screw part (110) is provided with an external thread I (111), the external thread I (111) is a right-handed thread, and the inner wall of the inner nut (120a) is provided with an internal thread I (120a-...

Embodiment 2

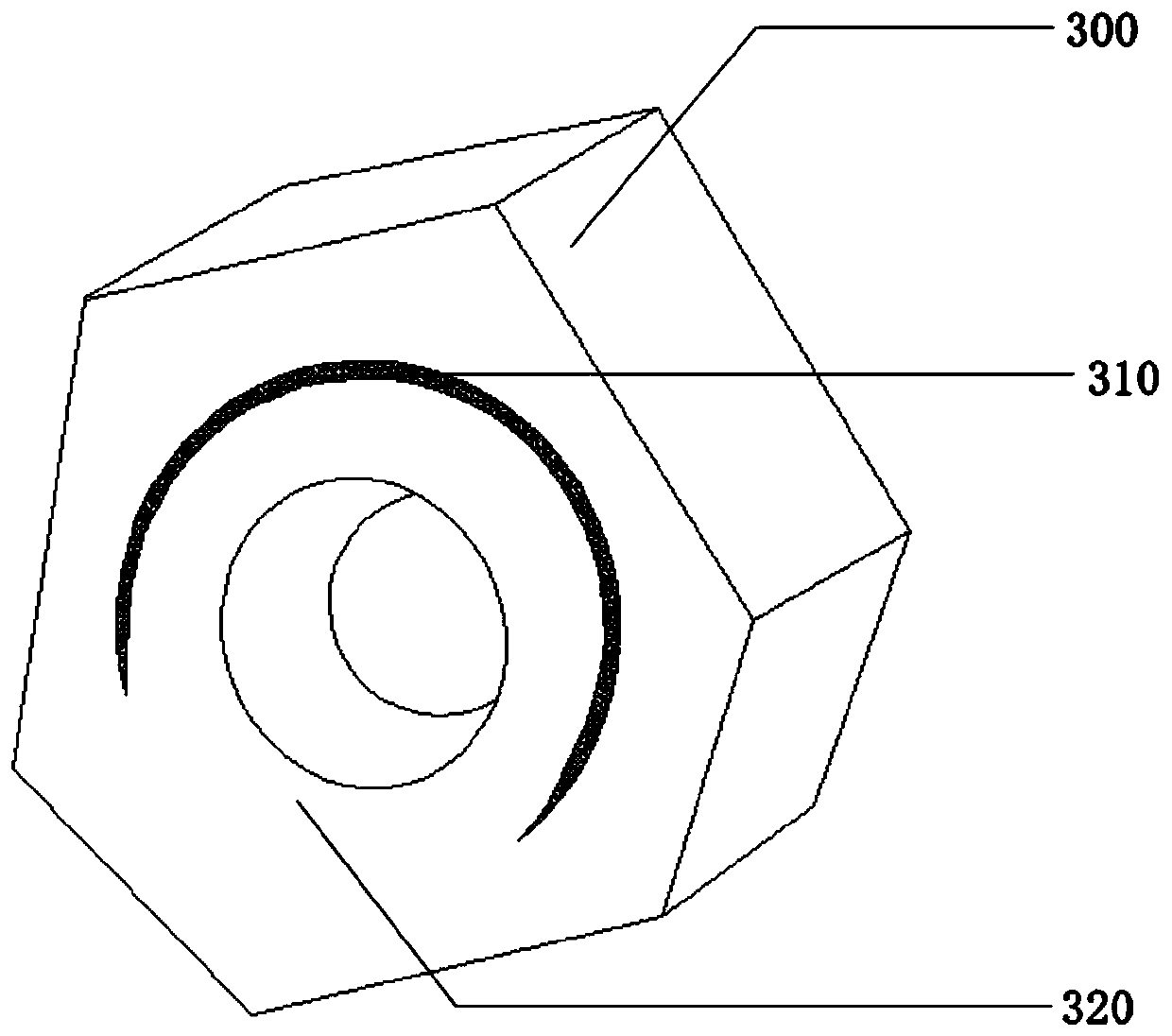

[0056] Different from Example 1, as Figure 5 As shown, an anti-loosening connection pair includes an eccentric bolt (100), a locking bolt (200) and a backstop (300), the backstop (300) is a backnut, and the eccentric bolt (100) It includes a screw part (110) and an inner nut (120a), the stop nut is sleeved on the screw part (110), and the inner nut (120a) is a groove opened at one end of the screw part (110) , the central axis of the screw part (110) and the central axis of the inner nut (120a) are not on the same straight line. The locking bolt (200) is coaxially provided with a flange part I (210), a boss part I (220) and a bolt part (230) connected in sequence, and the bolt part (230) is connected to the inner nut (120a ) threaded connection.

[0057] The outer wall of the screw part (110) is provided with an external thread I (111), the external thread I (111) is a right-handed thread, and the stop nut is provided with a The same internal thread II (330), the internal ...

Embodiment 3

[0062] Different from Example 1, as Figure 6-8 As shown, an anti-loosening connection pair includes an eccentric bolt (100), a lock nut (400) and a backstop (300), the backstop (300) is a backwash washer, and the eccentric bolt (100 ) includes an integral screw part (110) and an extension bolt (120b), the anti-backwash washer is sleeved on the screw part (110), and the central axis of the screw part (110) is aligned with the extension bolt ( 120b) are not on the same straight line. The lock nut (400) includes a flange part II (410), a boss part II (420) and a nut part (430) coaxially arranged, and the nut part (430) passes through the flange part II ( 410 ), at the axis of the boss portion II ( 420 ), the nut portion ( 430 ) is threadedly connected with the extension bolt ( 120 b ).

[0063] The anti-retraction washer is sheathed on the screw part (110) of the eccentric bolt (100) through interference fit. An external thread I (111) is provided on the outer wall of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com