A track-type underground mechanical and electrical equipment transportation device

A technology of electromechanical equipment and transportation devices, which is applied in underground transportation, transportation and packaging, earthwork drilling and mining, etc. It can solve problems such as increased workload, prone to tripping, and impact on safety, so as to reduce contact friction and avoid rotation deviation. Move, improve the effect of passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

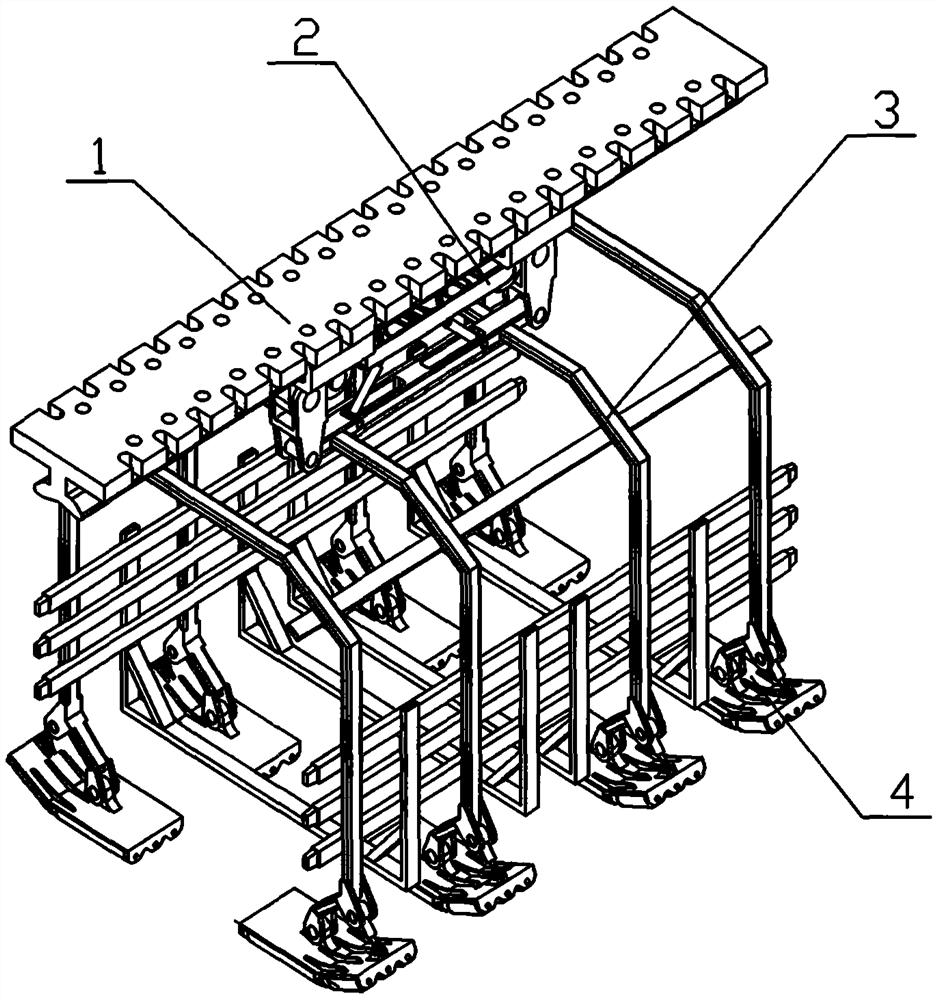

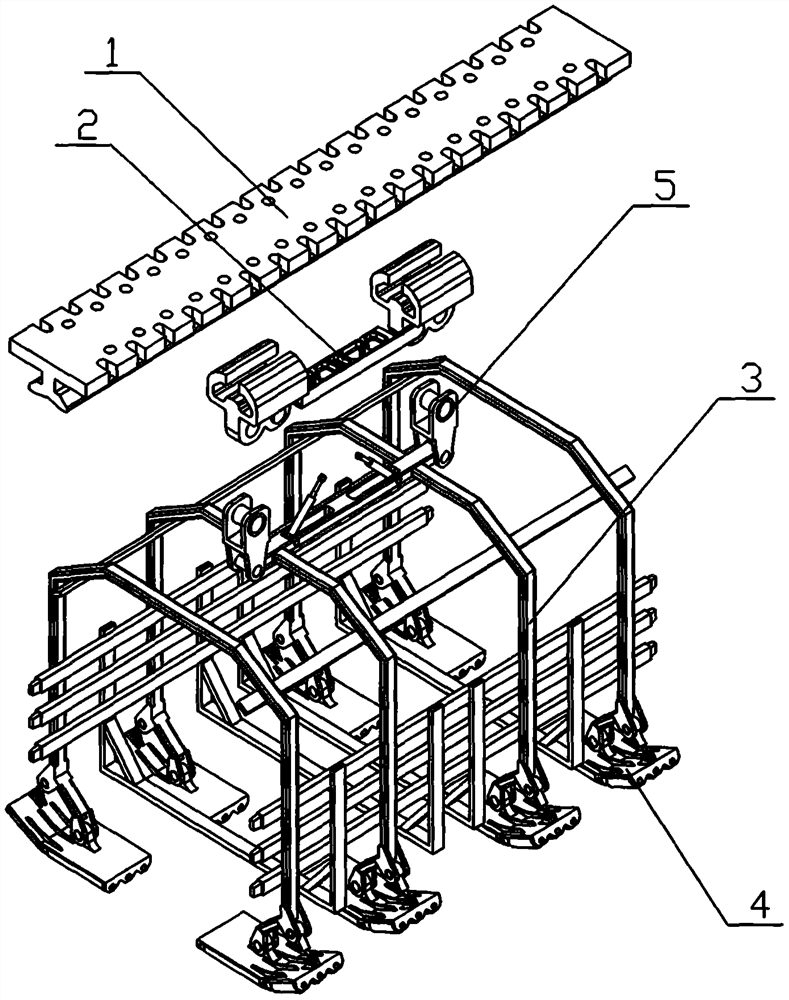

[0032] A track 1 type underground electromechanical equipment transportation device of the present invention is realized in the following way: a track 1 type underground electromechanical equipment transportation device of the present invention includes a track 1, a suspension frame 2, a car 3 and a bottom guide part 4, and the suspension frame 2 hangs Placed on the track 1, the suspension frame 2 can slide along the track 1, the car 3 is fixed on the lower side of the suspension frame 2, and two sets of supporting and guiding parts are symmetrically placed at the bottom of the car 3, and the supporting and guiding parts can be opposite to the car. compartment 3 deflected,

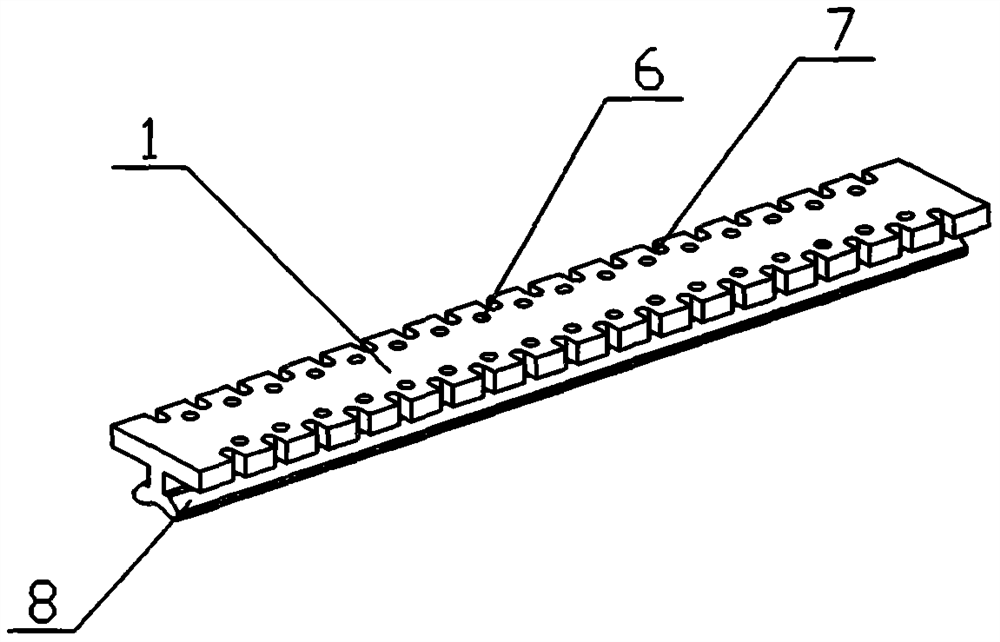

[0033] The cross-section of the track 1 is "T" shape, sliding grooves 8 are respectively opened on both sides of the vertical plate of the "T" shape structure, and run through the two ends of the track 1 respectively, and the bottom of the "T" shaped vertical plate is opened with Groove, two groups of open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com