Adjustable filtering, impurity removing and edge polishing device on tempered glass production line

A technology for filtering and removing impurities and tempering glass, which is applied in grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc. It can solve the problems of large contact area between glass and table top, non-guided grinding, and inconvenient glass movement. Achieve the effects of easy cleaning and replacement, cleaning glass surface and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

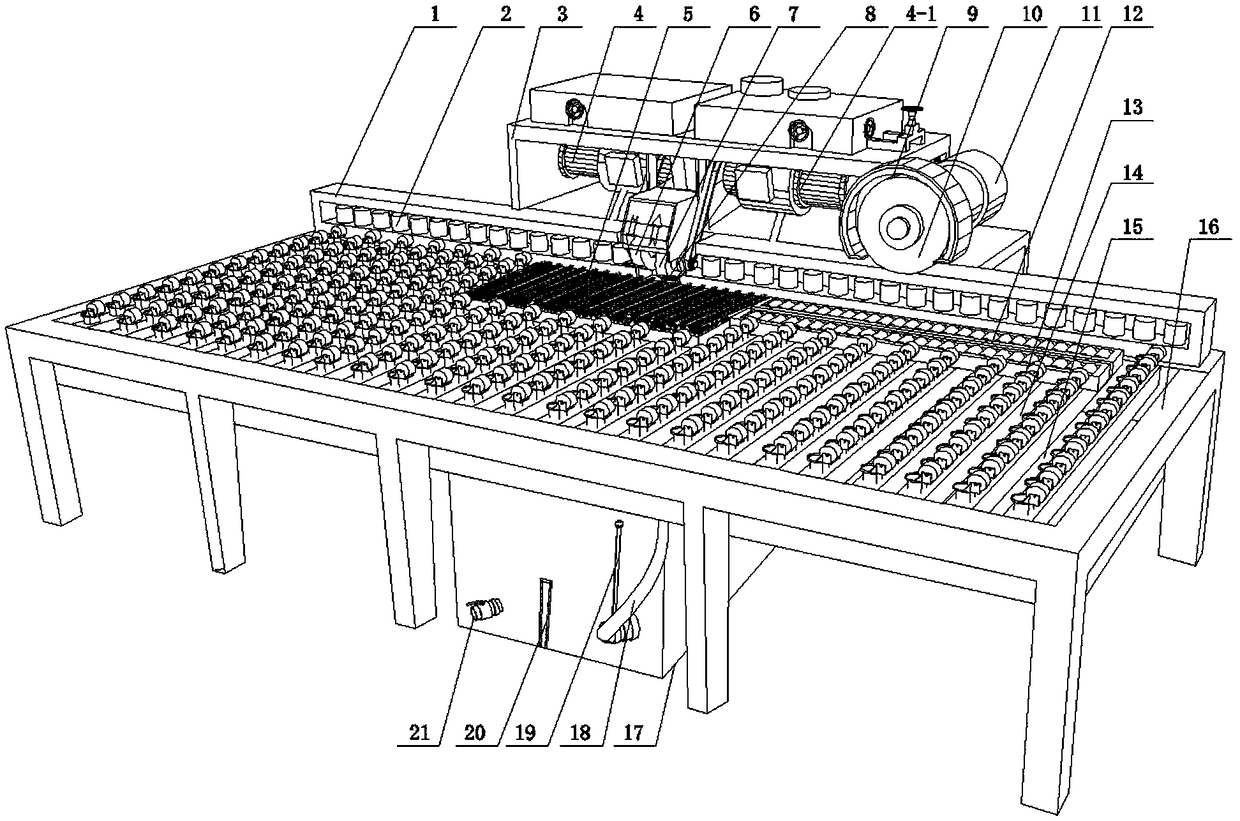

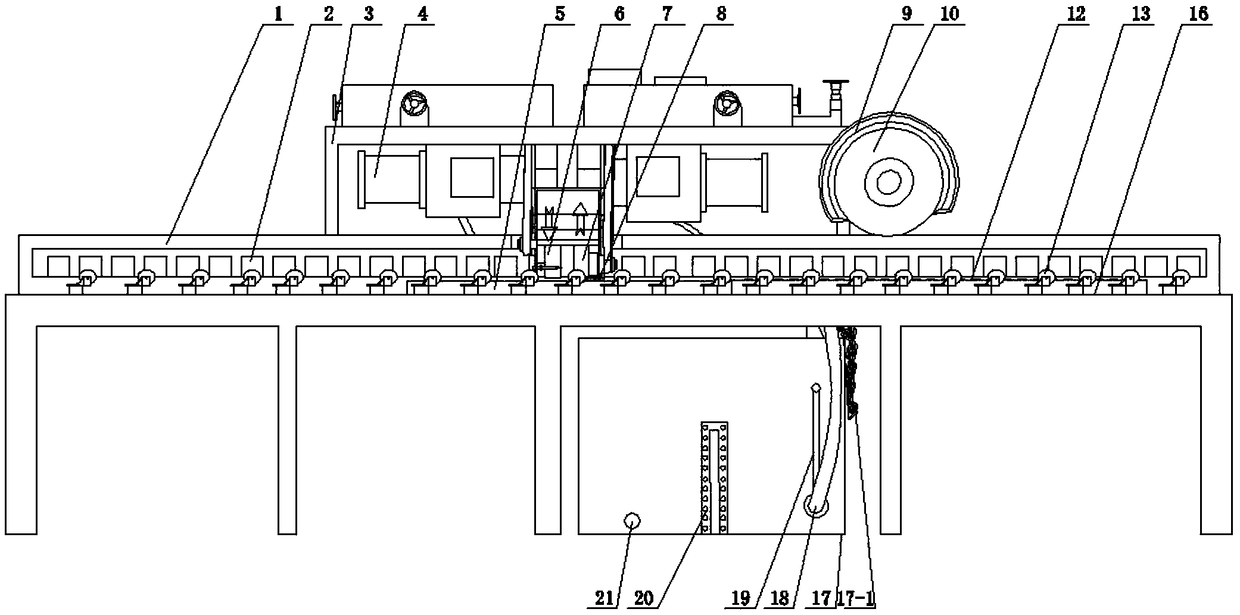

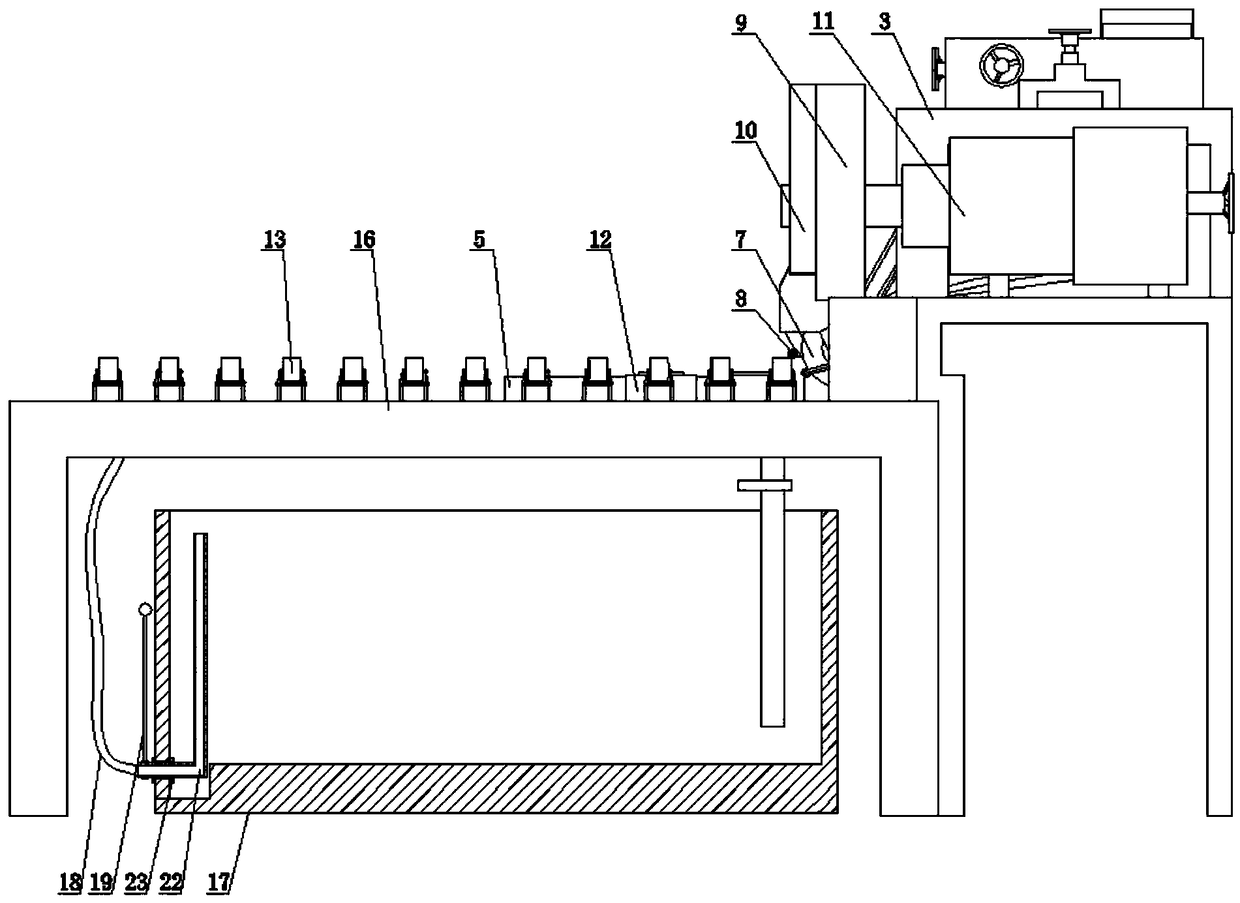

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0031] An adjustable filtering impurity removal and edging device on a tempered glass production line, including a grinding platform, a grinding mechanism, a flushing mechanism, and a sedimentation drainage mechanism. A grinding mechanism is installed on one side of the grinding platform, and the grinding wheel side of the grinding mechanism is A flushing mechanism is installed, and the sedimentation drainage mechanism is set at the lower part of the support of the grinding platform. The sedimentation drainage mechanism and the flushing mechanism are connected through a water pipe with a pump. The glass is placed horizontally on the grinding platform, and the edge of the glass passes through the grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com