A segmented preforming method for torsion beams

A pre-formed, segmented technology used in beams, forming tools, and elongated structural members for load-bearing, etc., which can solve the problem of rotational offset, torsion beam performance effects, and "V"-shaped R-angle modeling. Uniformity and other issues to achieve the effect of preventing rotation offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, the technical solution of the present invention will be described in detail through specific examples.

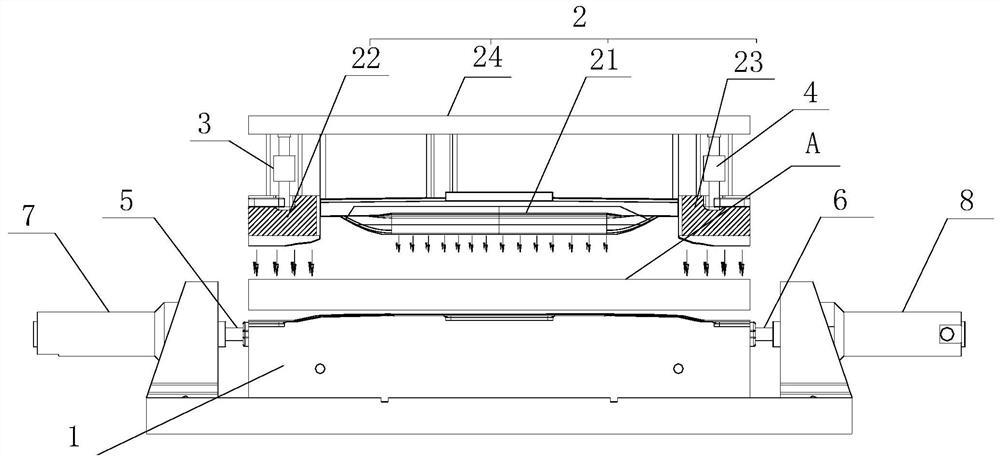

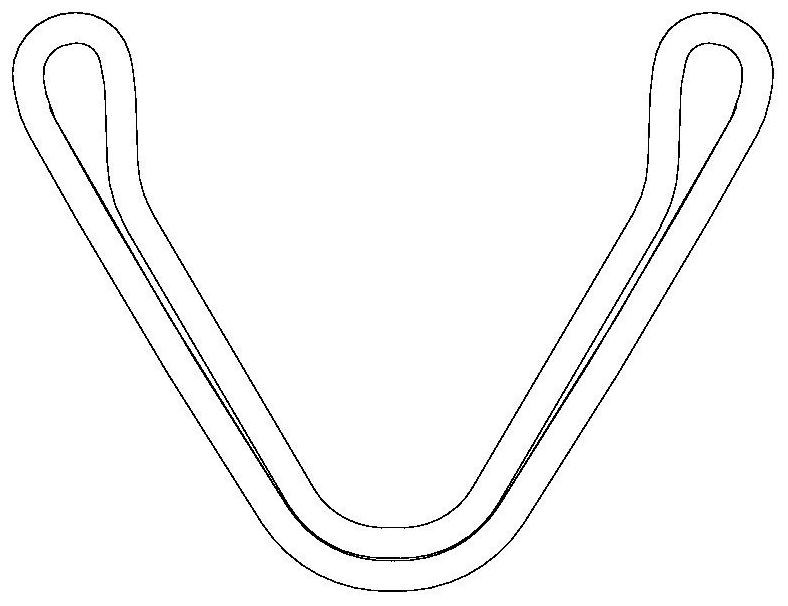

[0021] Such as Figure 1-3 as shown, figure 1 It is a schematic structural diagram of split preforming equipment in a torsion beam segmental preforming method proposed by the present invention; figure 2 It is a schematic diagram of the product structure processed by a torsion beam segmental preforming method proposed by the present invention; image 3 It is a schematic structural diagram of a "V"-shaped R-angle shape in a product processed by a torsion beam segmental preforming method proposed by the present invention.

[0022] refer to figure 1 , a kind of torsion beam segmental preforming method that the present invention proposes, comprises the following steps:

[0023] S1. Raw material selection: select the corresponding pipe material A as the processing base material according to the needs;

[0024] S2. Press the selected pipe material A to form a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com