An automatic bagging device for blow molding waste crushing

A bagging device and waste technology, applied in the direction of packaging automatic control, packaging, solid materials, etc., can solve the problems of troublesome bag replacement, waste of manpower and time, etc., to achieve easy bag replacement, prevent the rotation deviation of the bag mouth, and accurately rotate The effect of the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

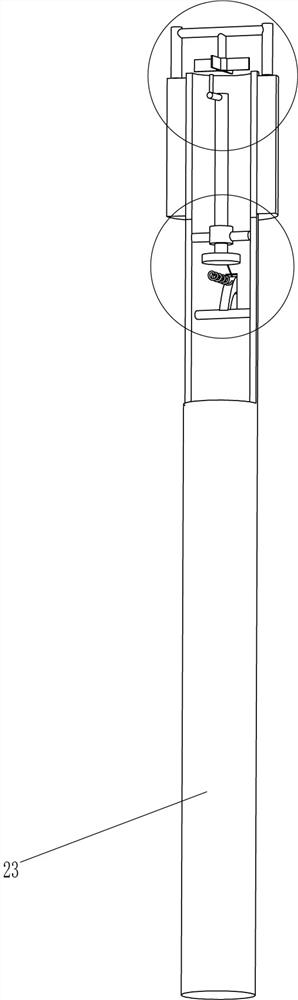

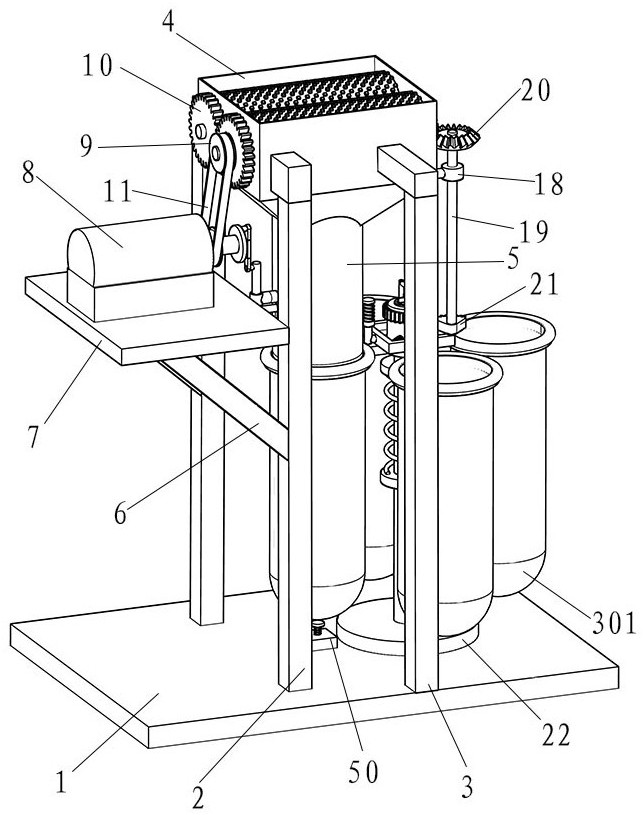

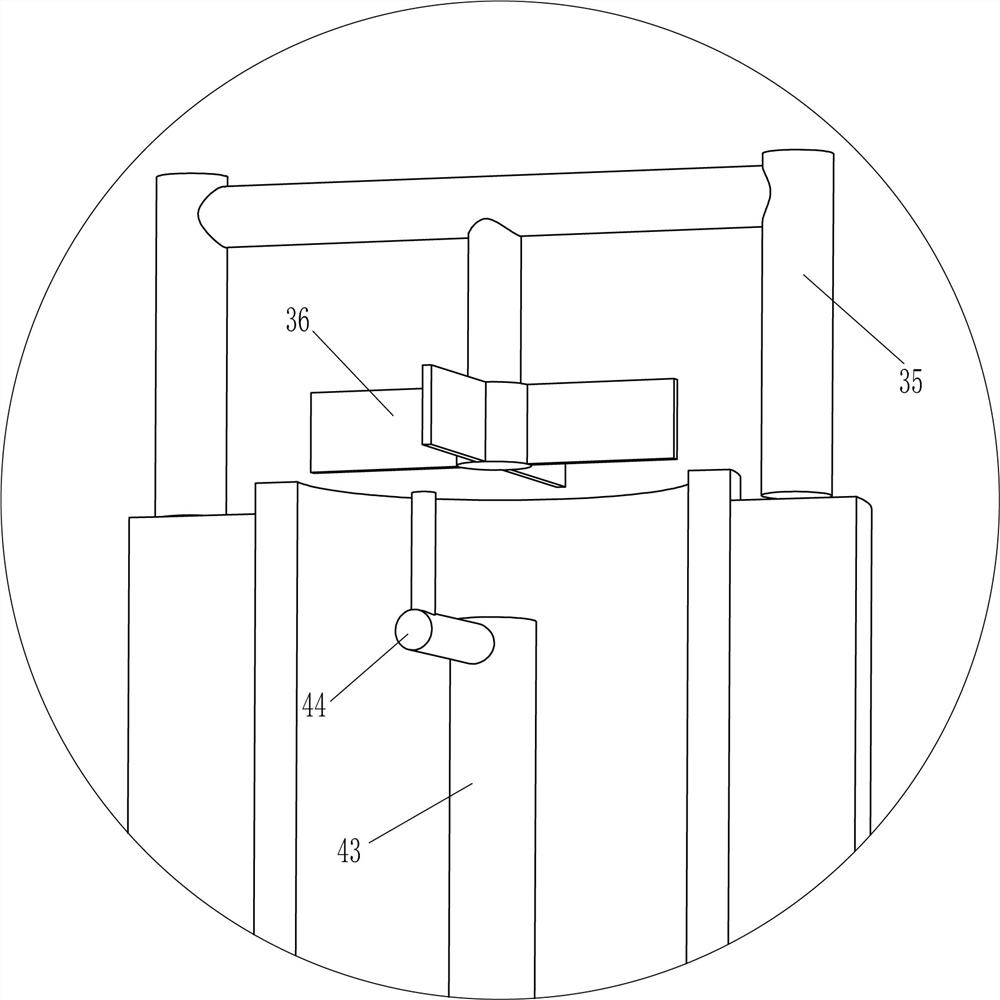

[0030] An automatic bagging device for blow molding waste crushing, see Figure 1-8 , including a bottom plate 1, a first bracket 2, a second bracket 3, a pulverizer 4, a lower barrel 5, a support block 6, a support plate 7, a motor 8, a transmission wheel 9, a first gear 10, a first belt 11, Pressing assembly, base 22, hollow pipe 23, fixed ring 24, rotating assembly, clamping assembly and first spring 26, the first bracket 2 and the second bracket 3 are all connected by bolts on the front and rear sides of the bottom plate 1 top, the first The bracket 2 is located on the left side of the second bracket 3, the upper part between the first bracket 2 and the second bracket 3 is installed with a pulverizer 4 through bolts, the bottom of the pulverizer 4 is connected with the lower barrel 5, and the left middle of the two first brackets 2 Both support blocks 6 are connected, and the support blocks 6 are inclined. The tops of the two support blocks 6 are connected with a support p...

Embodiment 2

[0039] On the basis of Example 1, see figure 1 , Figure 4 , Figure 9 , Figure 10 and Figure 11 , also includes metal ball 32, telescoping rod 31, second spring 33, fourth guide sleeve 45, slide bar 46, block 47, fourth spring 48 and rectangular frame 49, and the outside of sliding sleeve 28 is embedded with two A telescopic rod 31, a metal ball 32 is connected to the outer end of the telescopic rod 31, a second spring 33 is connected between the metal ball 32 and the sliding sleeve 28, the second spring 33 is wound on the telescopic rod 31, and the lower part of the lower right side of the lower barrel 5 is connected to A fourth guide sleeve 45 is arranged, and a slide bar 46 is slidably provided in the fourth guide sleeve 45. The top end of the slide bar 46 is connected with a stopper 47, and a fourth spring 48 is connected between the stopper 47 and the fourth guide sleeve 45. Four springs 48 are wound on the slide bar 46, and the right end of the slide bar 46 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com