Reed for camera lens drive mechanism

A lens drive and camera technology, applied in installation, optics, instruments, etc., can solve problems such as easy deformation of spring wire, deviation of concentricity and optical axis degree of lens support body, displacement deviation of optical axis direction, etc., to improve the ability of anti-deformation , avoid rotation offset, and improve impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

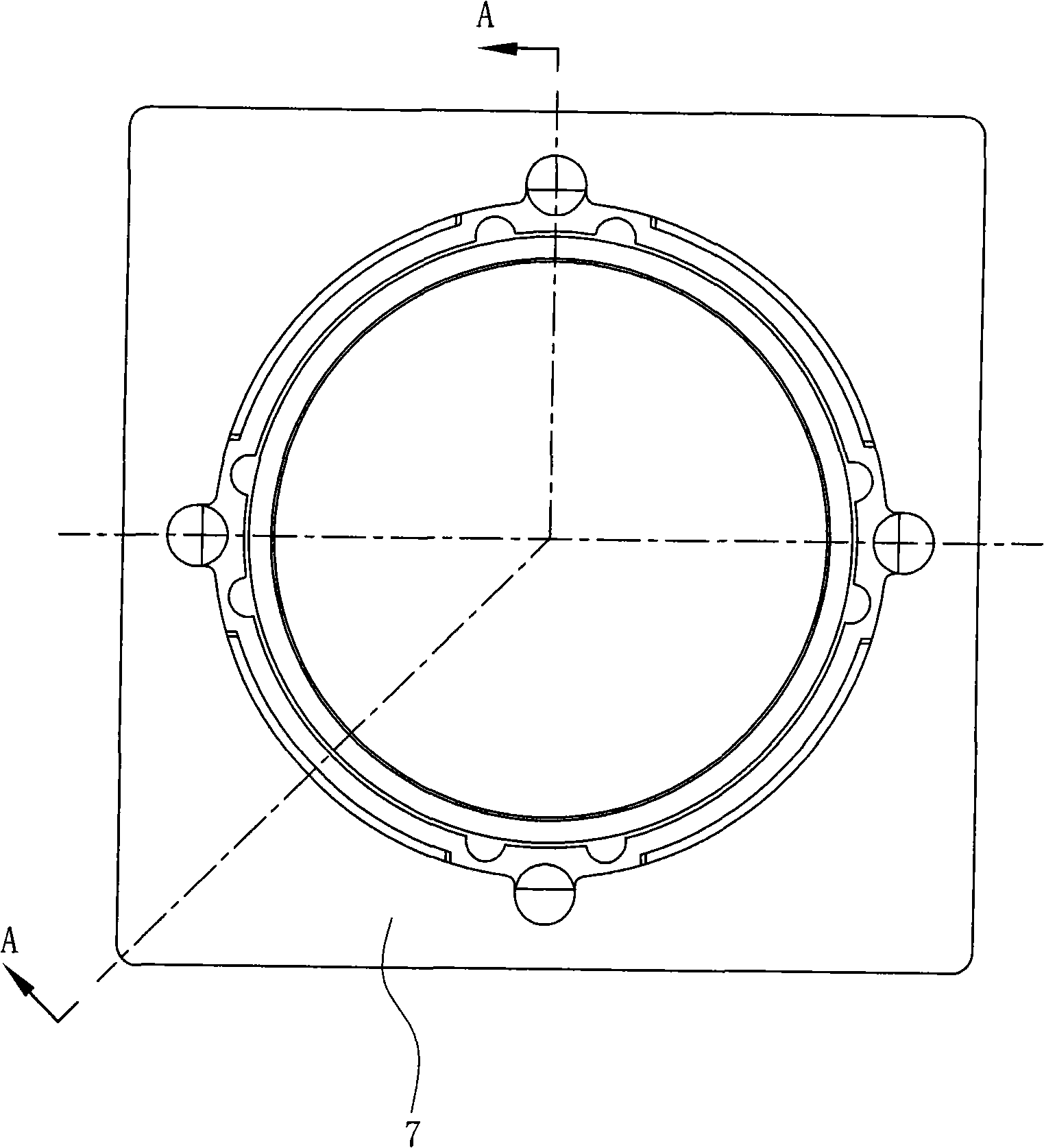

[0024] Such as Figure 1~4 Shown is a preferred embodiment of the present invention.

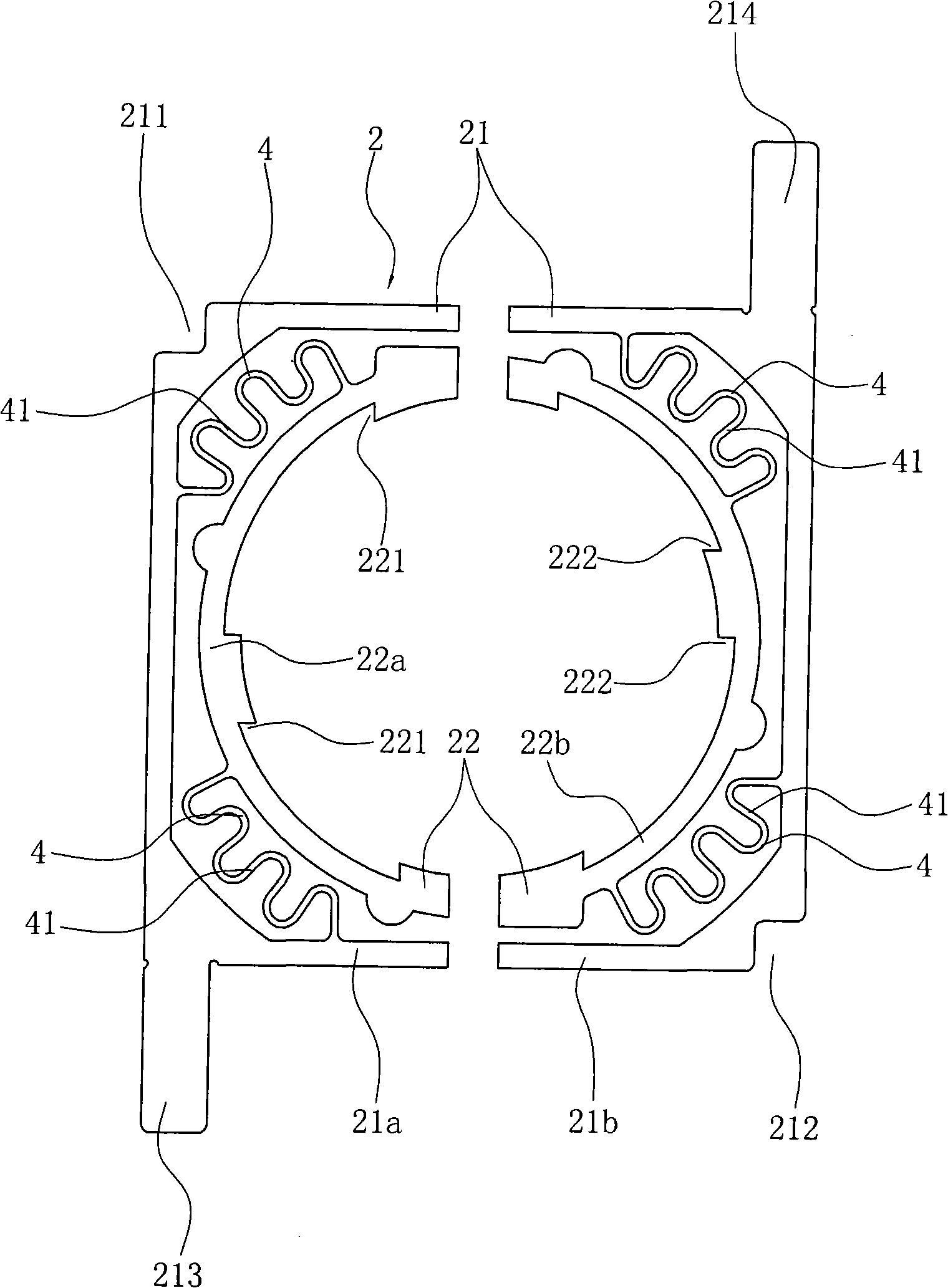

[0025] A reed for a camera lens drive mechanism. Generally, there are two types of reeds in a camera lens drive mechanism, namely the front reed 1 and the rear reed 2. The front and rear reeds 1 and 2 are integrally formed into a thin sheet .

[0026] Now set forth the concrete structure of front reed 1 and rear reed 2.

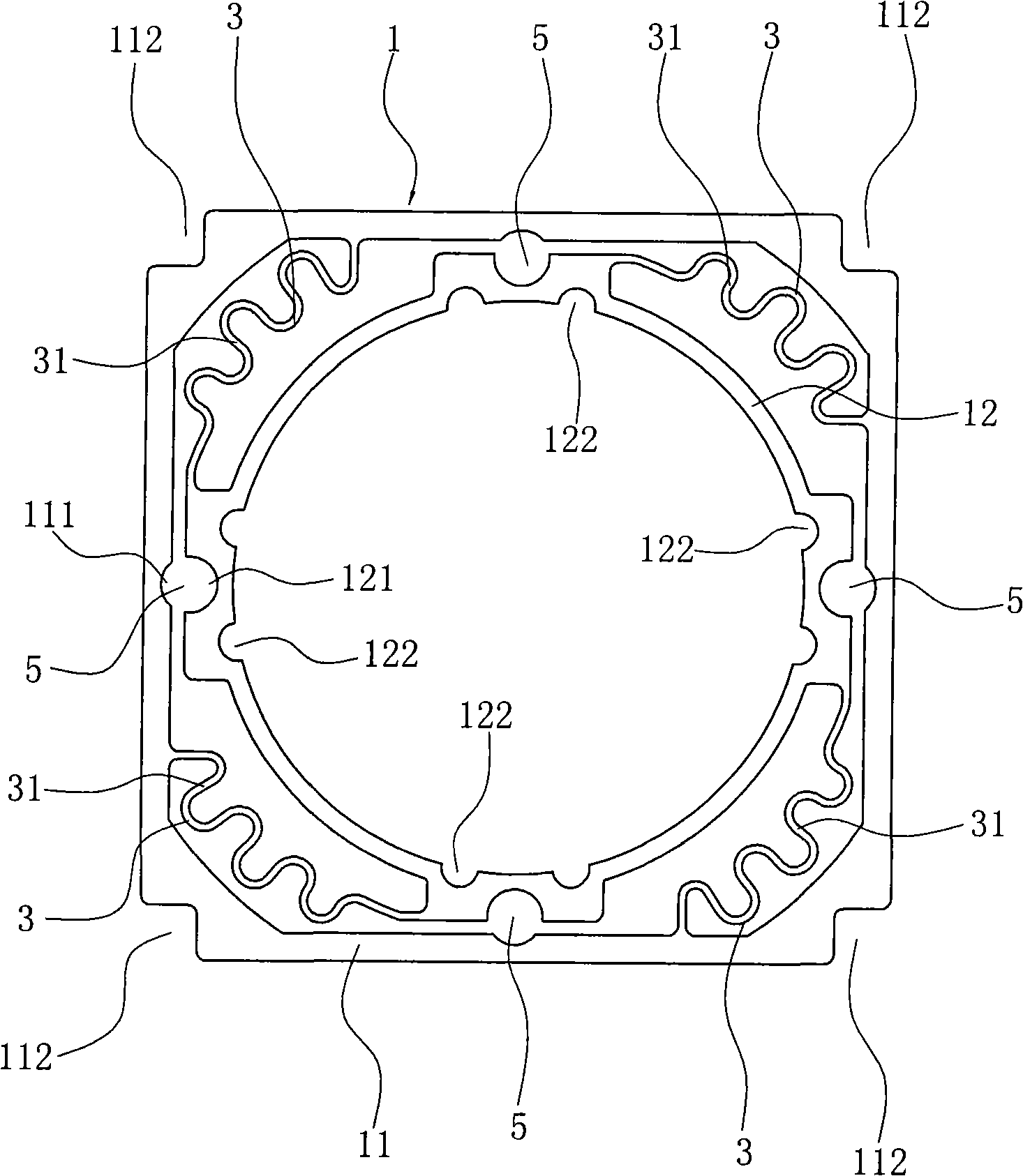

[0027] The front reed 1 is composed of an annular outer profile 11 and an annular inner profile 12, and the outer profile 11 and the inner profile 12 are both integral.

[0028] Wherein, the outer frame 11 is in a square shape, and each of the four outer corners of the outer frame 11 is provided with an L-shaped glue joint opening 112 facing outward.

[0029] The inner profile 12 is circular, and the inner profile 12 is located in the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com