Medicinal material multistage grinding device for biological pharmacy and biopharmaceutical system

A grinding device and biological technology, applied in the fields of application, grain processing, food science, etc., can solve the problems of low grinding efficiency, rigid structure, single function, etc., to improve the grinding efficiency and grinding effect, the structure is ingenious, and the layout is reasonable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

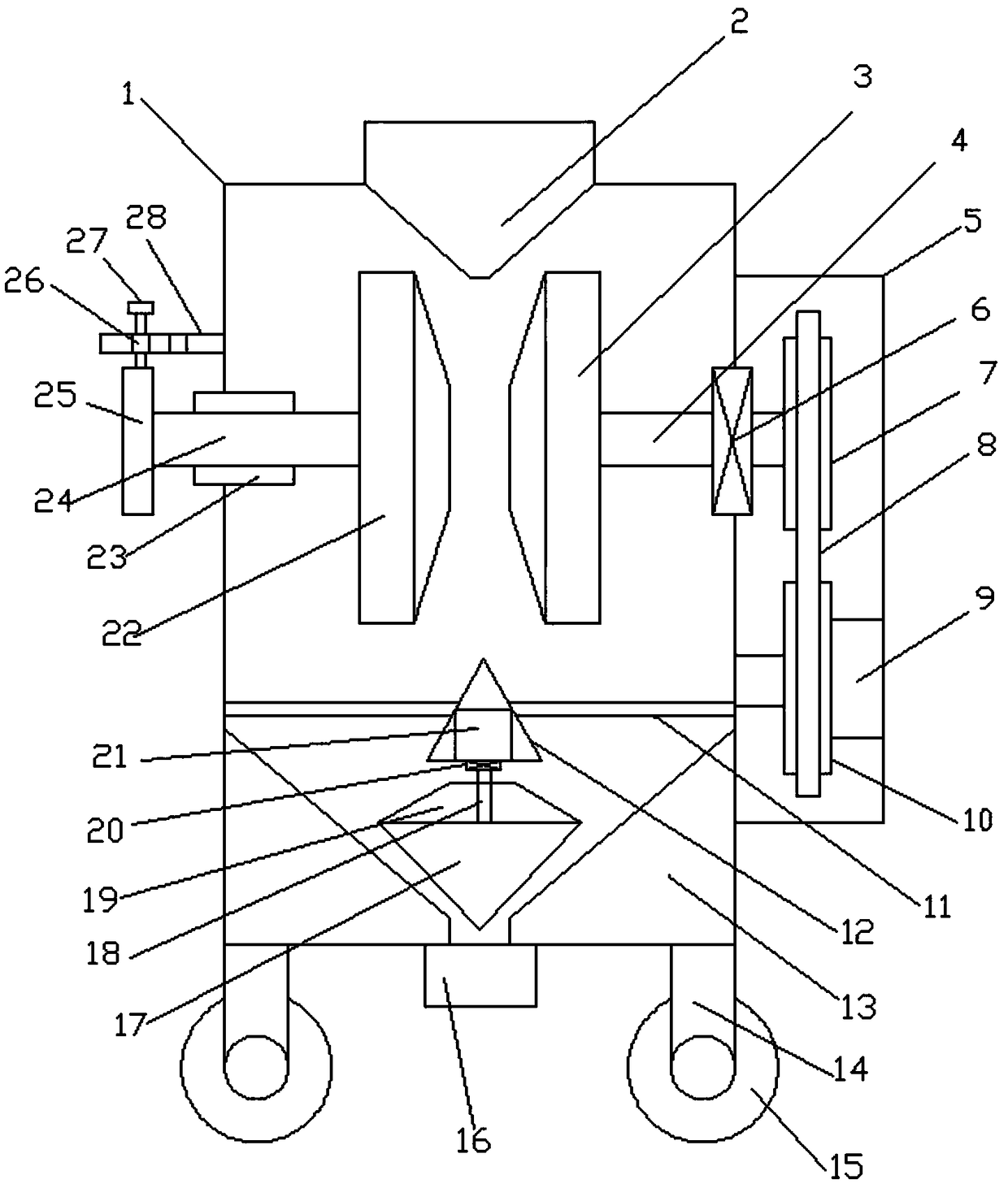

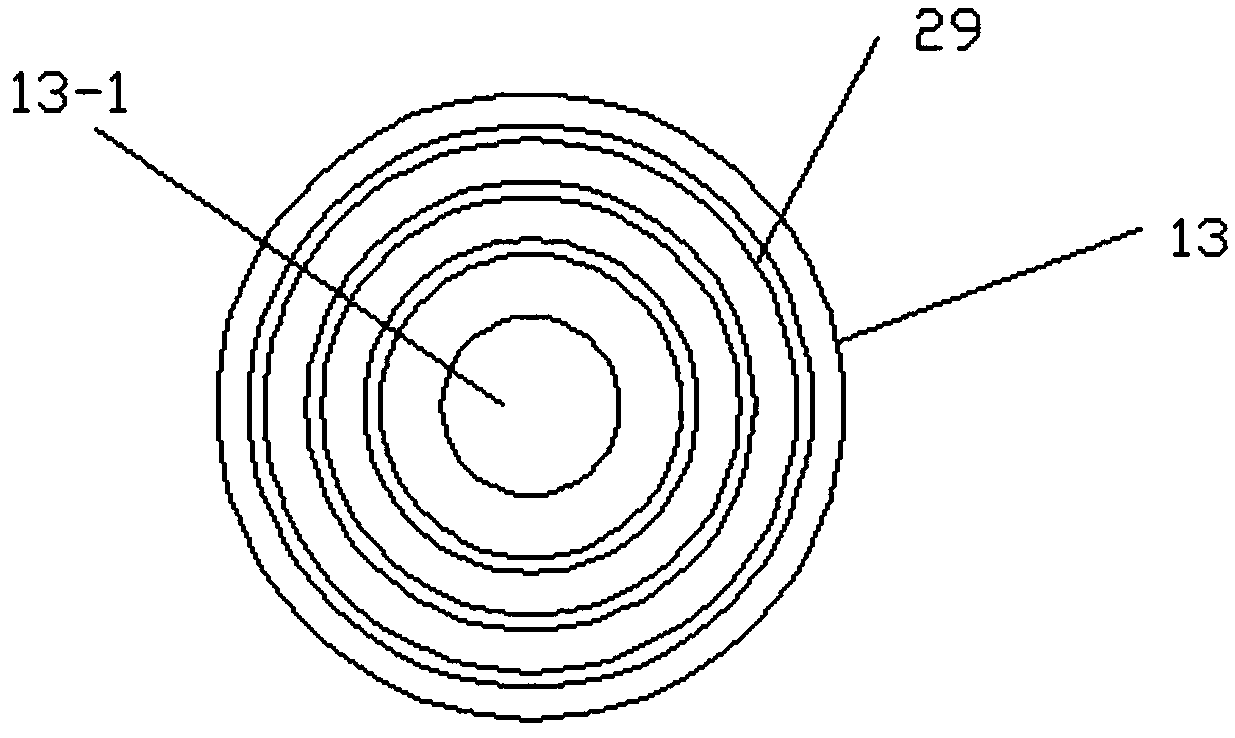

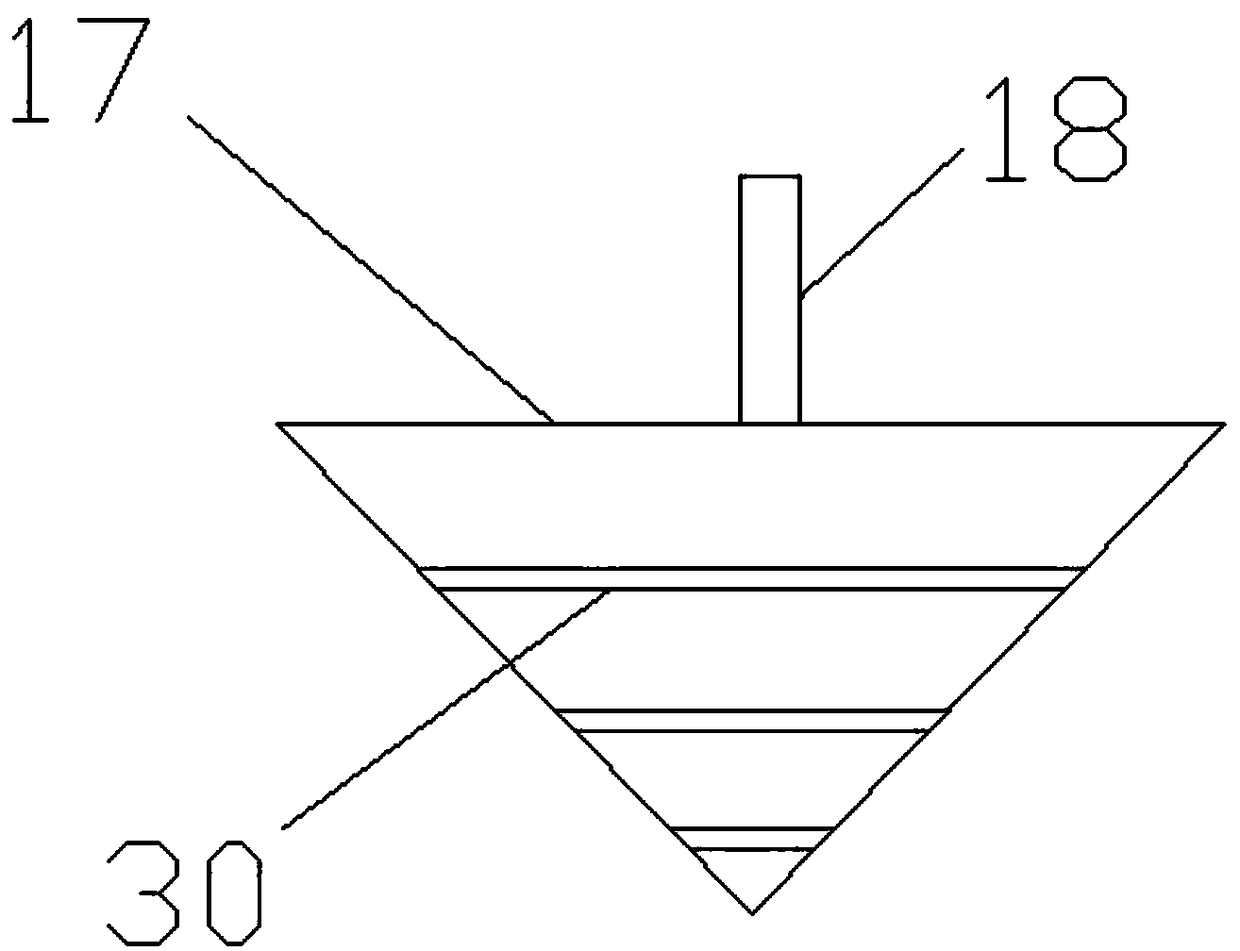

[0021] Example 1: See Figure 1~4 , in an embodiment of the present invention, a multi-stage grinding device for biopharmaceutical medicinal materials, comprising a housing 1, a feeding hopper 2 is arranged on the top of the housing 1, and a fixing device is arranged below the feeding hopper 2 corresponding to the housing 1. The grinding disc 22 and the movable grinding disc 3, the fixed grinding disc 22 and the movable grinding disc 3 are symmetrically arranged left and right along the lower side of the feed hopper 2, and the movable grinding disc 3 is set on the first set of the corresponding position on the right side wall of the housing 1 through the horizontal rotating shaft 4. On the bearing 6, a first machine compartment 5 is arranged on the right side of the housing 1, and the right end of the horizontal rotating shaft 4 extends into the first machine compartment 5, and a horizontal rotating shaft drive mechanism is arranged in the first machine compartment 5, so that ...

Embodiment 2

[0027] Embodiment 2: The only difference between this embodiment and Embodiment 1 Technical features: the fixing mechanism includes a fixing rod 24, the fixing rod 24 is a threaded rod, and the left side of the housing 1 is fixedly provided with a threaded sleeve 23. The threaded sleeve 23 runs through the left side wall of the casing 1, the fixed rod 24 is set in the threaded sleeve 23, the fixed grinding disc 22 is fixed on the right end of the fixed rod 24 in the casing 1, and the casing 1 The left end of the outer fixed rod 24 is provided with a manual turntable 25 , and the top of the housing 1 is provided with a limit mechanism corresponding to the manual turntable 25 .

[0028] The limit mechanism includes a horizontal limit rod 28, which is horizontally arranged on the side wall of the housing 1 above the manual turntable 25, and the horizontal limit rod 28 is evenly arranged with vertical bars from left to right. The socket 26, the outer side of the manual turntable 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com