Furnace door body structure for diffusion furnace

A technology of diffusion furnace and furnace door, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of complex structure of boat feeding mechanism and low production efficiency, and achieve simple structure, improve production efficiency and reduce occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

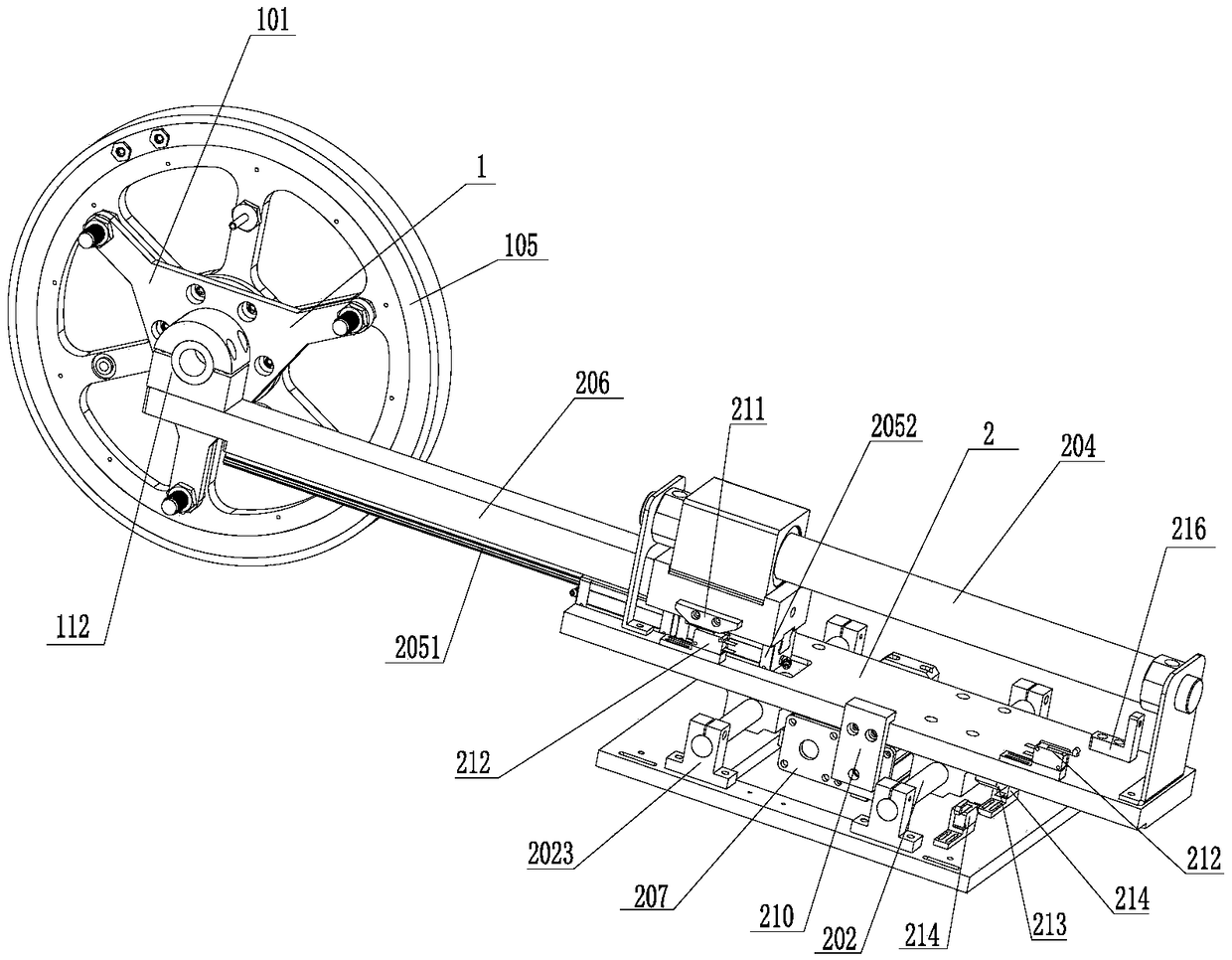

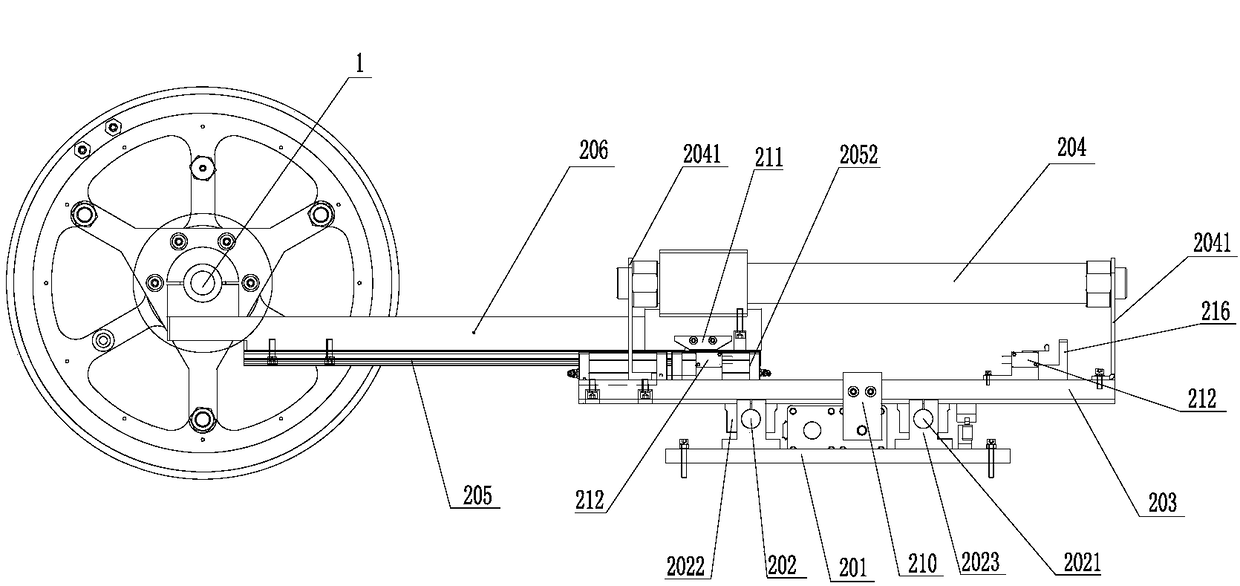

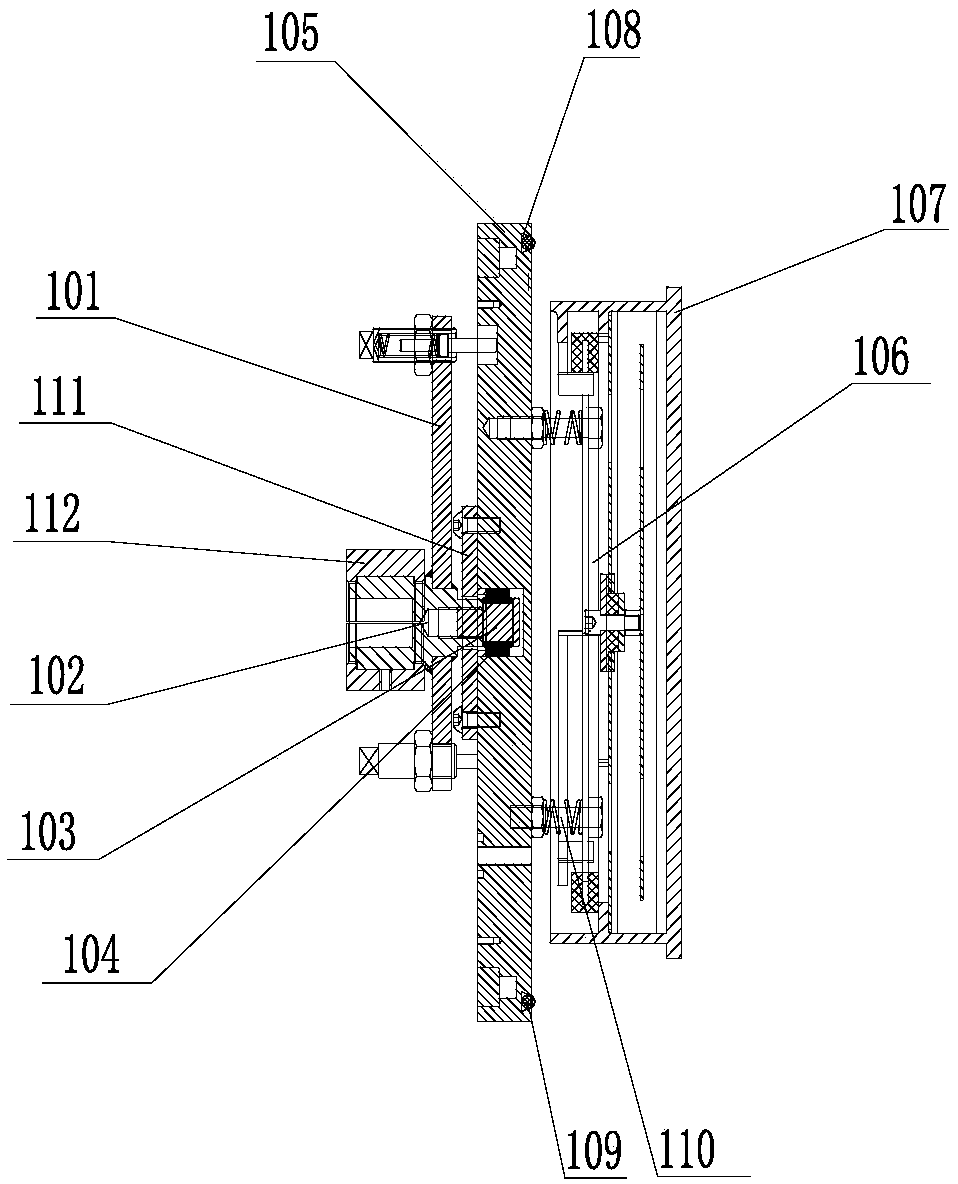

[0023] combine Figure 1 to Figure 4 , which describes a specific embodiment of the present invention in detail, but does not limit the claims of the present invention in any way.

[0024] Such as Figure 1 to Figure 4 As shown, a furnace door structure for a diffusion furnace, a furnace door body 1 and a furnace door driving mechanism 2;

[0025] The furnace door body 1 includes a furnace door support plate 101, a furnace door support shaft 102, a limit rotating shaft 103, a radial joint bearing 104, an aluminum door 105, a connecting plate 106 and a quartz door 107. The center of the furnace door support plate 101 is connected with Furnace door support shaft 102 is fixed with one side of aluminum door 105 by bolts around, and the center of one side of aluminum door 105 is equipped with radial joint bearing 104, and the other side is connected with one side of connecting plate 106 by spring bolt 110, and the other side of connecting plate 106 One side is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com