Clutch Driving Device

A driving device and clutch technology, applied to clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as increasing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

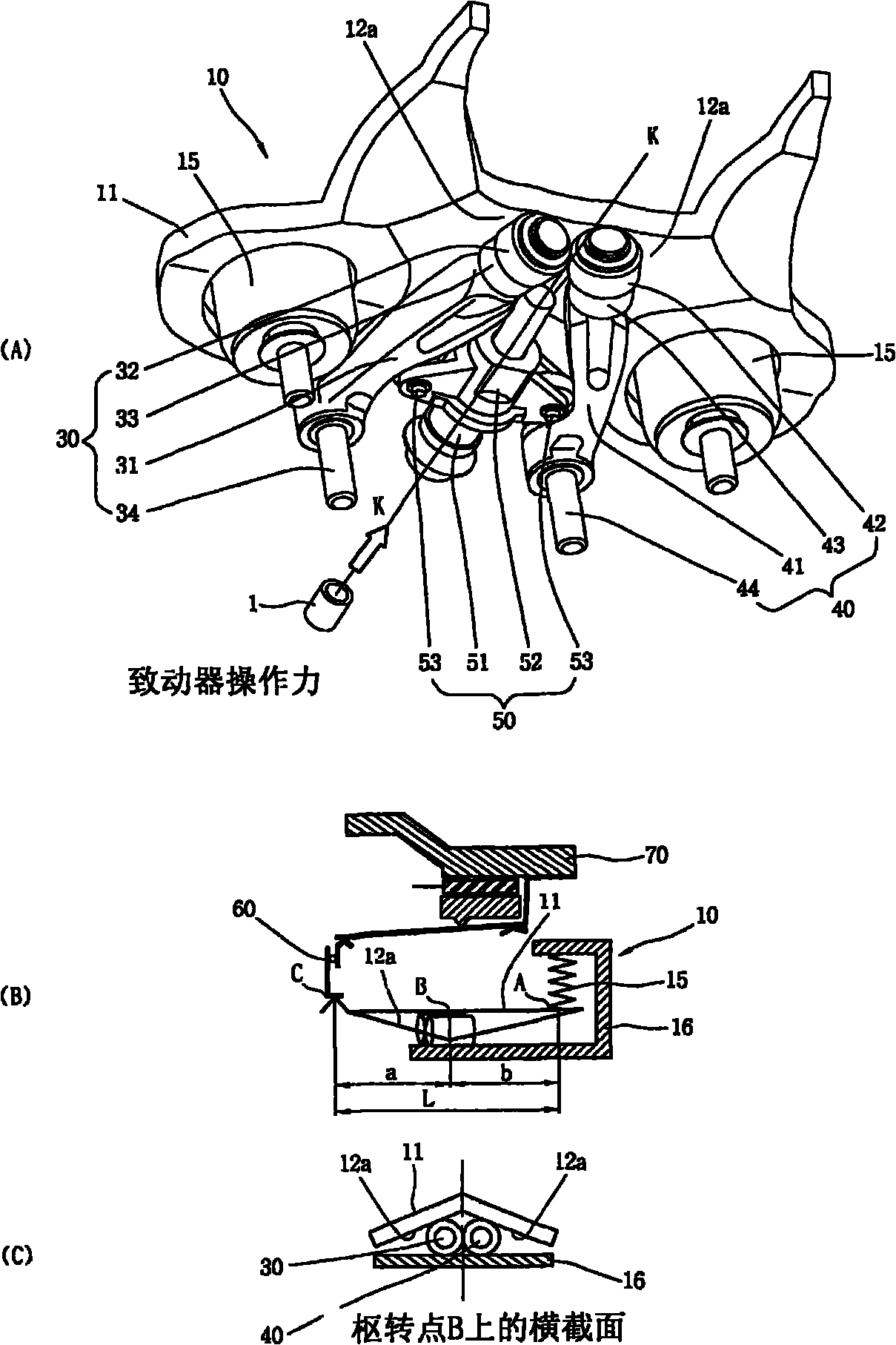

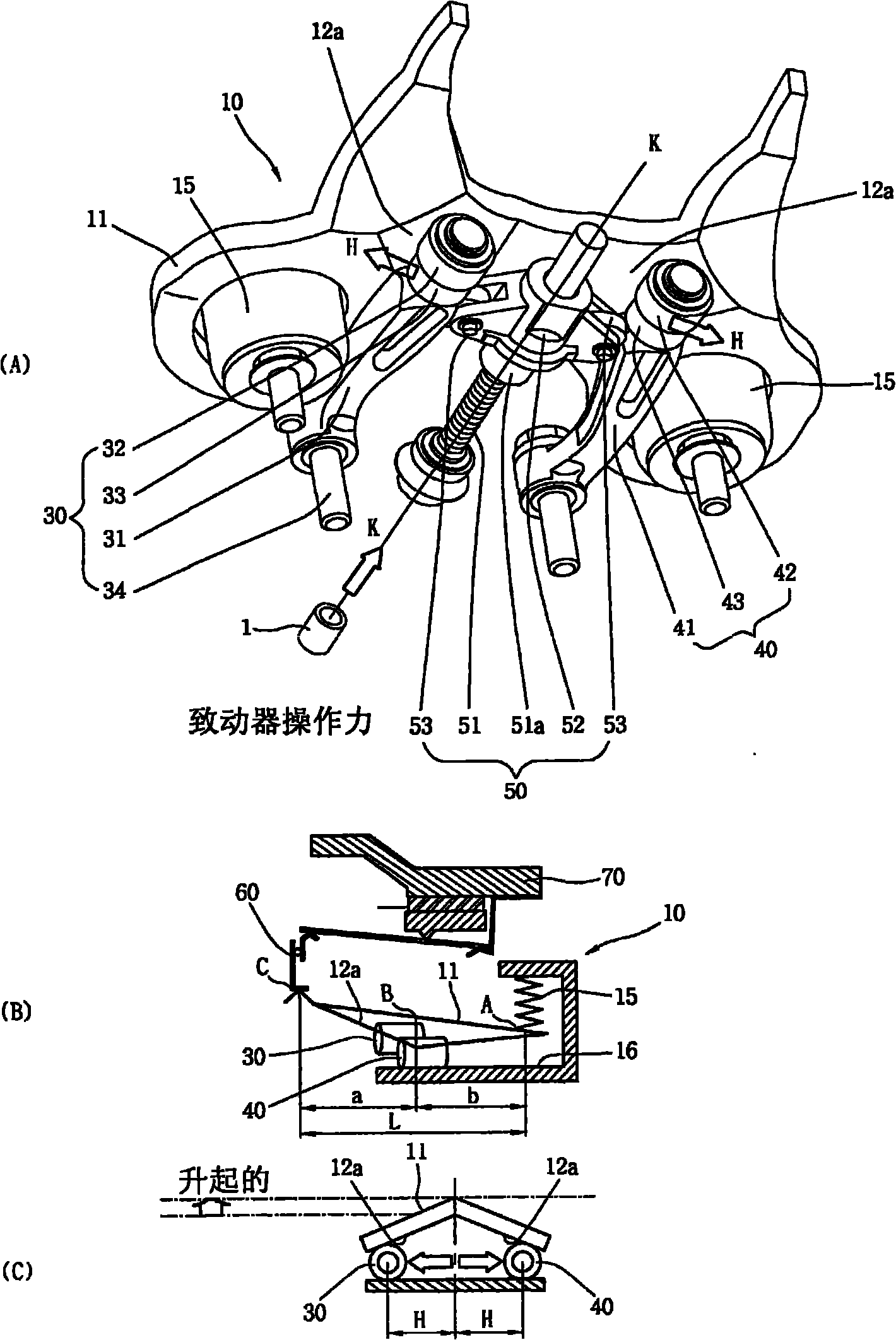

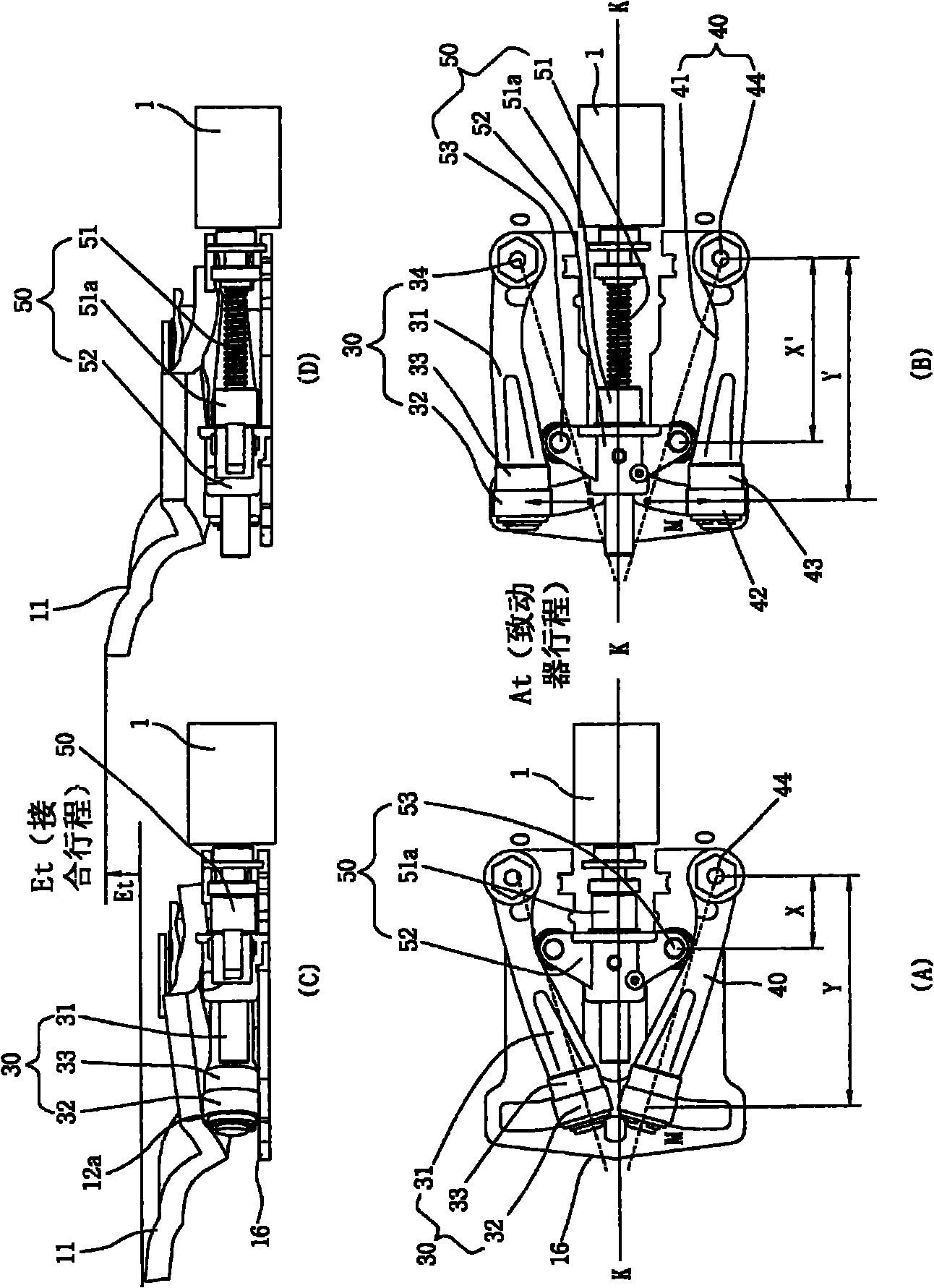

[0043] Such as figure 1 As shown, the clutch driving device includes an actuator 1 and an energy supply unit, the actuator 1 generates rotational power, and when the energy supply unit engages the clutch 70 by generating a stroke to the release bearing 60, the actuator 1 At the same time, the energy supply unit moves left and right relative to the two sides from the axial centerline K-K of the actuator 1 while converting the rotation into linear motion.

[0044] Although a motor is used as the actuator 1, an actuator utilizing hydraulic pressure or air pressure may also be used.

[0045] The clutch drive according to the invention is called a horizontal movement and vertical translation clutch drive (HVCDD), which is based on an energy supply unit arranged horizontally with respect to the axial centerline K-K of the actuator 1 side-to-side motion, and converts the horizontal motion into a squeezing force that squeezes the clutch by creating a vertical translation.

[0046] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com