Rivet nut electric tool

A technology of electric tools and rivet nuts, which is applied in the field of machinery, can solve the problems of unstable torsion spring torsion, prone to failure, large idle stroke, etc., and achieve the effects of strong motor gears, precise stroke control, and powerful power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

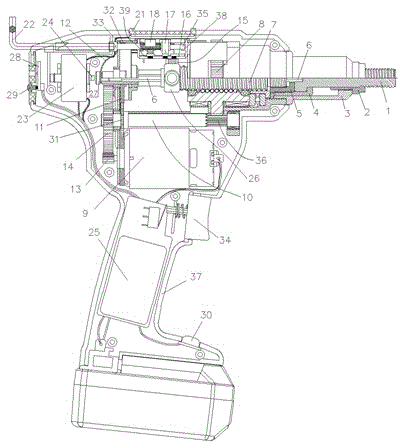

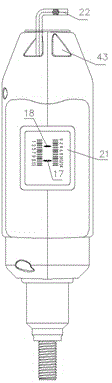

[0044] Such as figure 1 , Figure 4 and Figure 5 As shown, the rivet nut electric tool includes an outer cover 37, a pull rod 1, a gun head 2, an outer sleeve 3, a pull rod fixing lock nut 4, a screw lock nut 5, a hexagonal connecting rod 6, a gear transmission system, and a stroke Control system, screw nut assembly and clutch control system;

[0045] Described gear transmission system comprises motor 9, motor gear 13 and gear assembly, and described gear assembly comprises gear I14, gear II31 and connecting shaft 10, and connecting shaft 10 is provided with gear I14 and gear II31 successively from left to right, and connecting shaft The right end of 10 is processed with a hobbing gear 36, which can also be replaced by a gear at the right end of the connecting shaft 10; one end of the motor 9 is connected with the circuit board 25 fixed in the outer cover 37 through a control line, and the other end of the motor 9 is connected with a motor gear 13 ; The motor gear 13 is me...

Embodiment 2

[0057] Such as Figure 6 and Figure 7 As shown, the electromagnet control device includes a return spring II42, an electromagnet 23 and an electromagnet push rod 24; the return spring II42 is arranged between the gear I14 of the gear assembly and the positioning rear cover 33, and the left side of the gear I14 is arranged There is an electromagnet 23, and the right side of the electromagnet 23 is provided with an electromagnet push rod 24; the gear II31 of the gear assembly is arranged on the right side of the meshing gear of the gear clutch assembly 11; the hexagonal connecting rod 6 is fixedly connected with the right end of the shaft of the gear clutch assembly 11 . After the electromagnet 23 is energized, the electromagnet push rod 24 pushes the gear assembly to separate the meshing teeth of the gear II and the gear clutch assembly 11, and the hobbing teeth 36 on the connecting shaft 10 mesh with the meshing teeth on the screw nut 8 to perform riveting; When the electro...

Embodiment 3

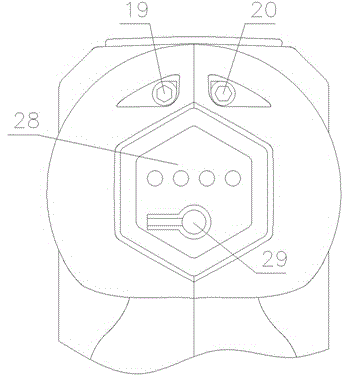

[0059] Such as Figure 8 and Figure 9As shown, the electromagnet control device includes back-moving spring 141, spring collar 40, electromagnet 23 and electromagnet push rod 24; Hexagonal structure, the right end of the shaft is processed with a connecting hole for connecting with the hexagonal connecting rod 6, the left end of the hexagonal connecting rod 6 is provided with a groove, and a spring collar 40 is fixed in the groove, and the return spring I41 is set on the hexagonal connecting rod 6 , one end is connected with the spring collar 40, and the other end is fixed on the stepped hole in the screw mandrel 7. The connection part processed at the front end of the shaft of the gear clutch assembly 11 is generally arranged in a hexagonal structure, which is used to connect with the connection hole processed at the left end of the hexagonal connecting rod 6, and the connecting hole is correspondingly arranged as a hexagonal hole. Under the action of the electromagnetic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com