Valve plate valve opening trimming device

A technology for trimming devices and valve holes, which is applied in the field of valve manufacturing, can solve problems such as slow working speed and affecting the installation of valve stems, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

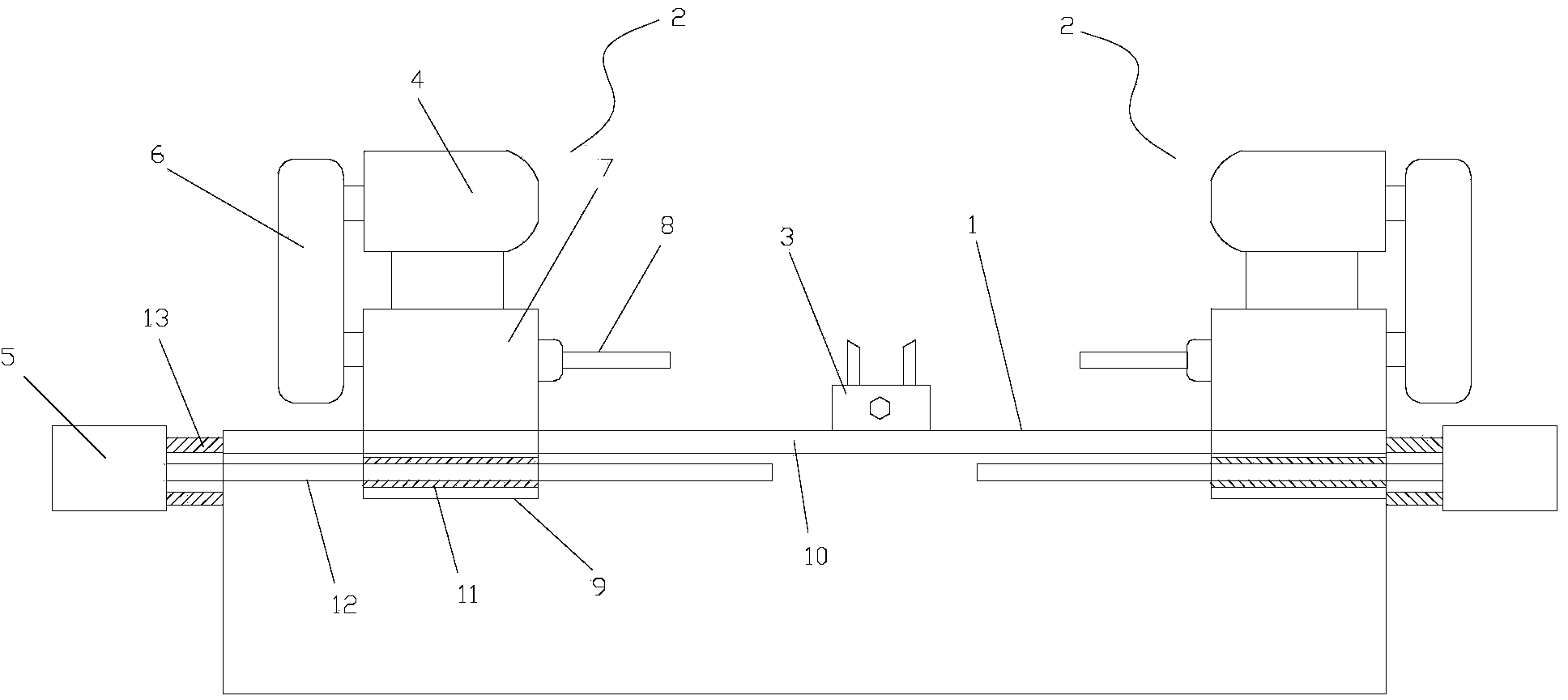

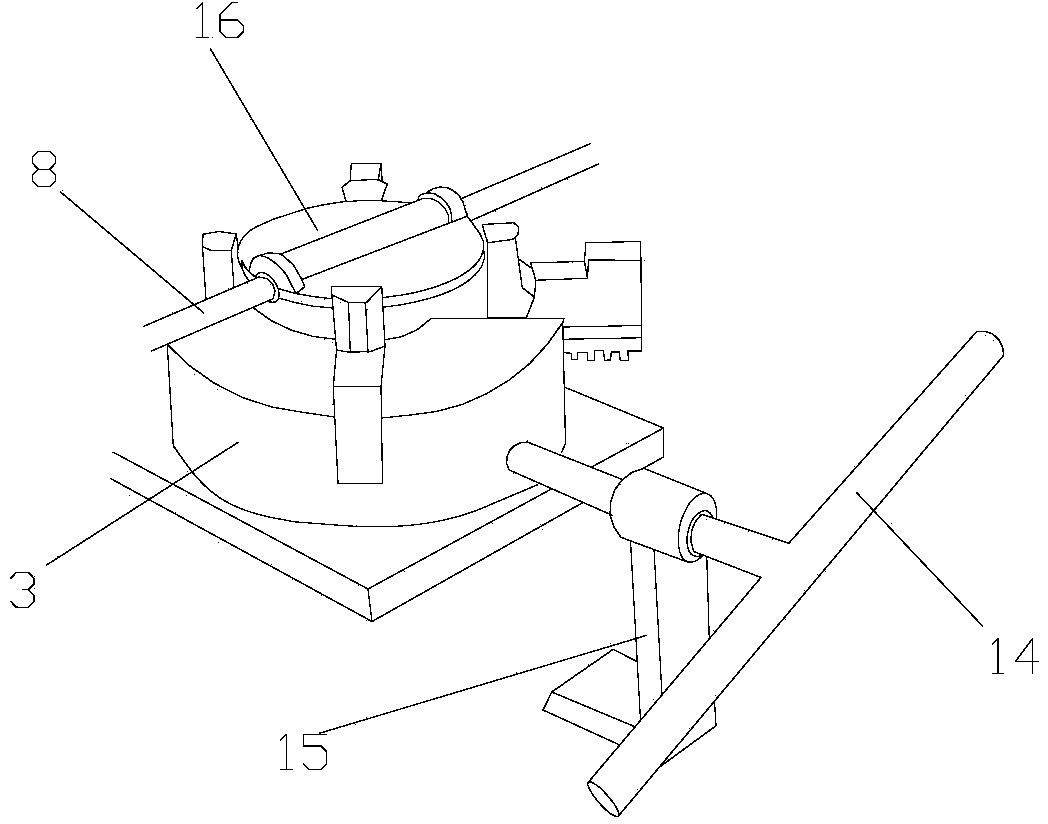

[0009] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a device for trimming the valve hole of a valve plate includes a workbench 1, a trimming mechanism 2 fixed on the workbench and a fastening mechanism 3 respectively. The trimming mechanisms are two sets, respectively fixed on the workbench, The fastening mechanism is located between the two sets of trimming mechanisms, and the trimming mechanism is mainly composed of a first motor 4, a second motor 5, a transmission box 6, a reduction box 7, and a milling cutter 8. On the upper part of the reduction box, the output end of the first motor is connected to the input end of the reduction box through the transmission box. There is a belt in the transmission box, and the two ends of the belt are respectively connected to the driving pulley on the first motor. Connect with the driven w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com