Sinker control device of sock knitting machine

A control device and technology of squeegee, applied in knitting, weft knitting, textiles and papermaking, etc., can solve problems such as inaccurate movement of shams, outward movement of shams, affecting the quality of hosiery, etc., and achieve an improvement The effect of hosiery quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

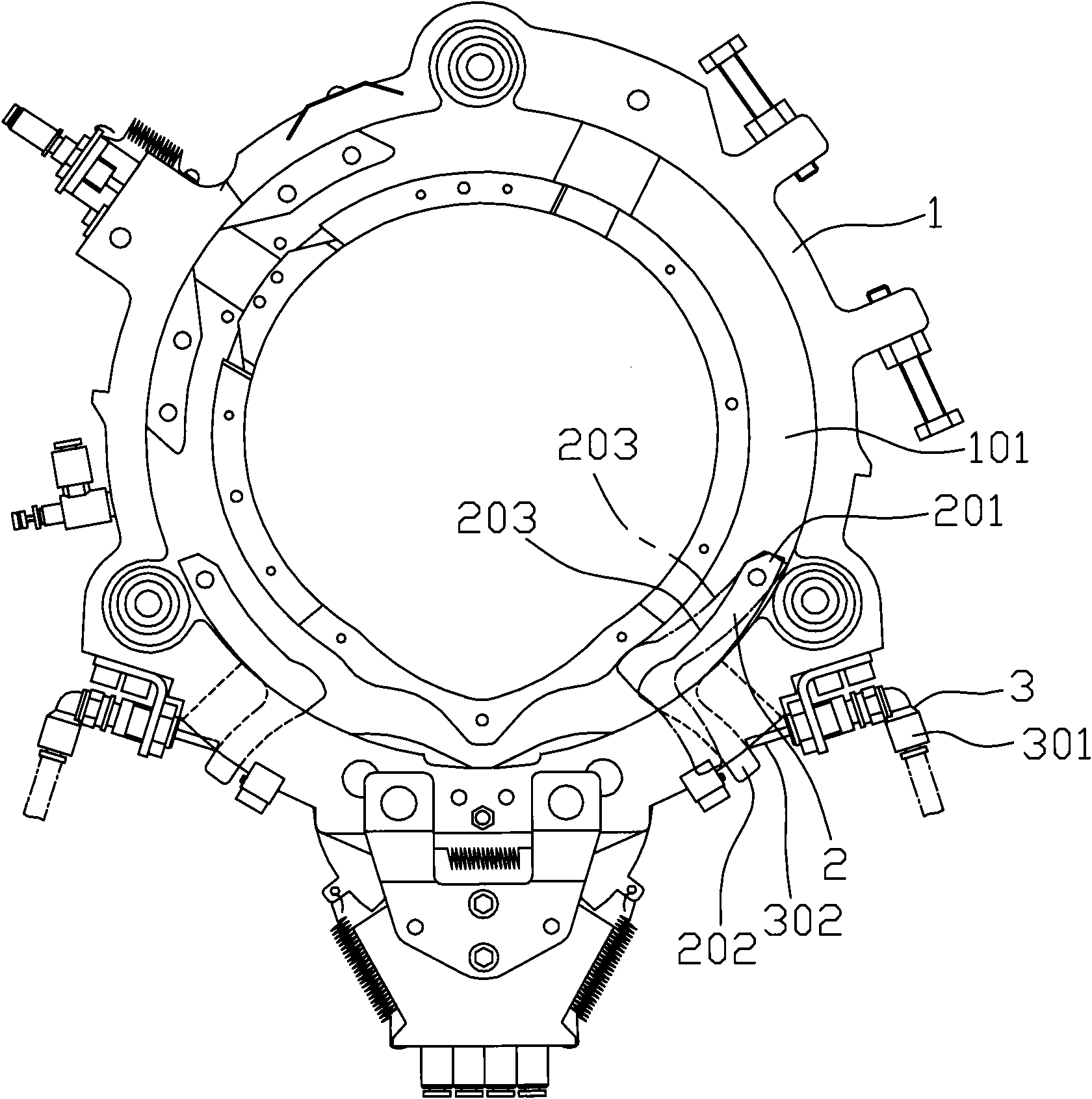

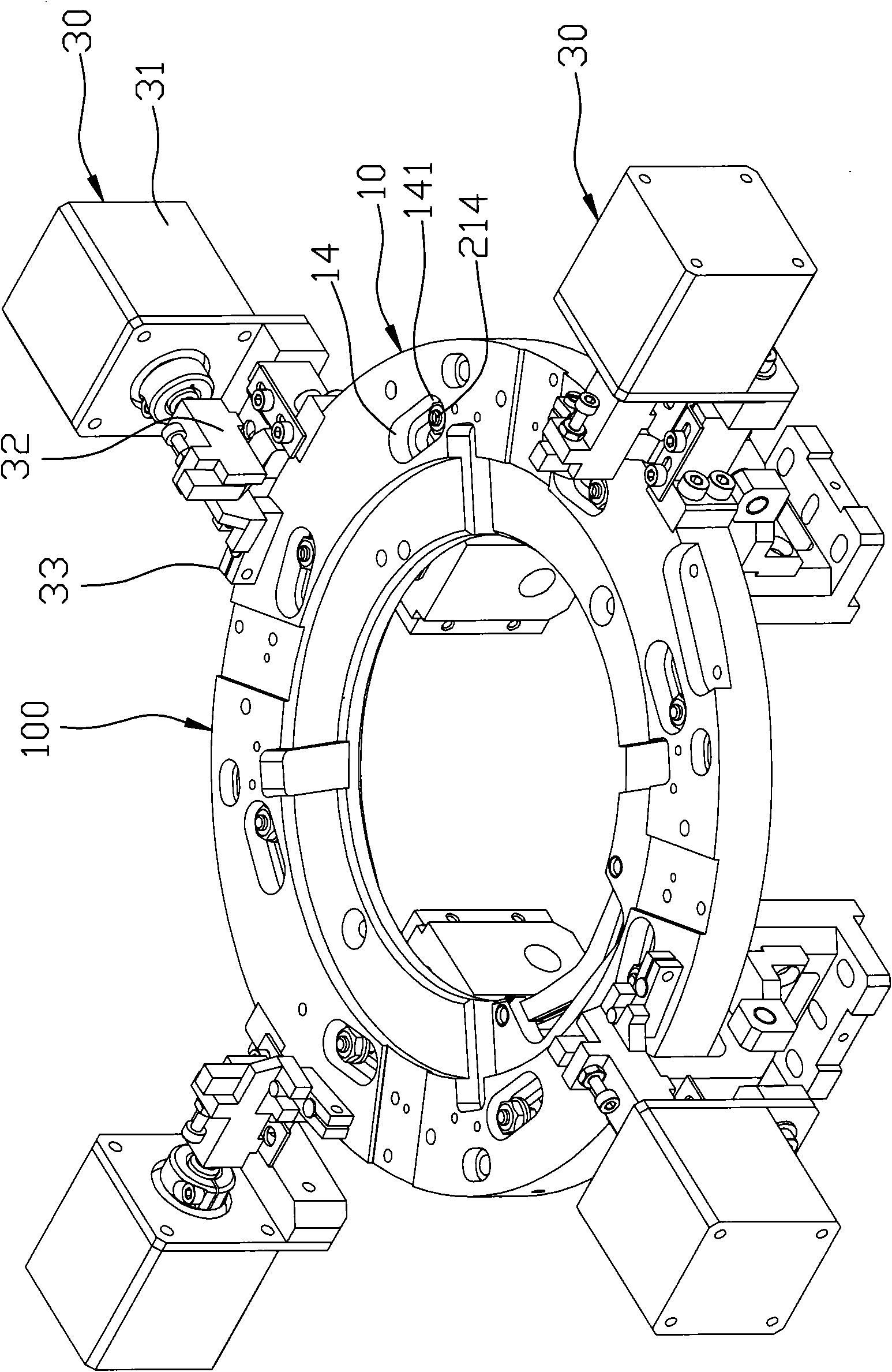

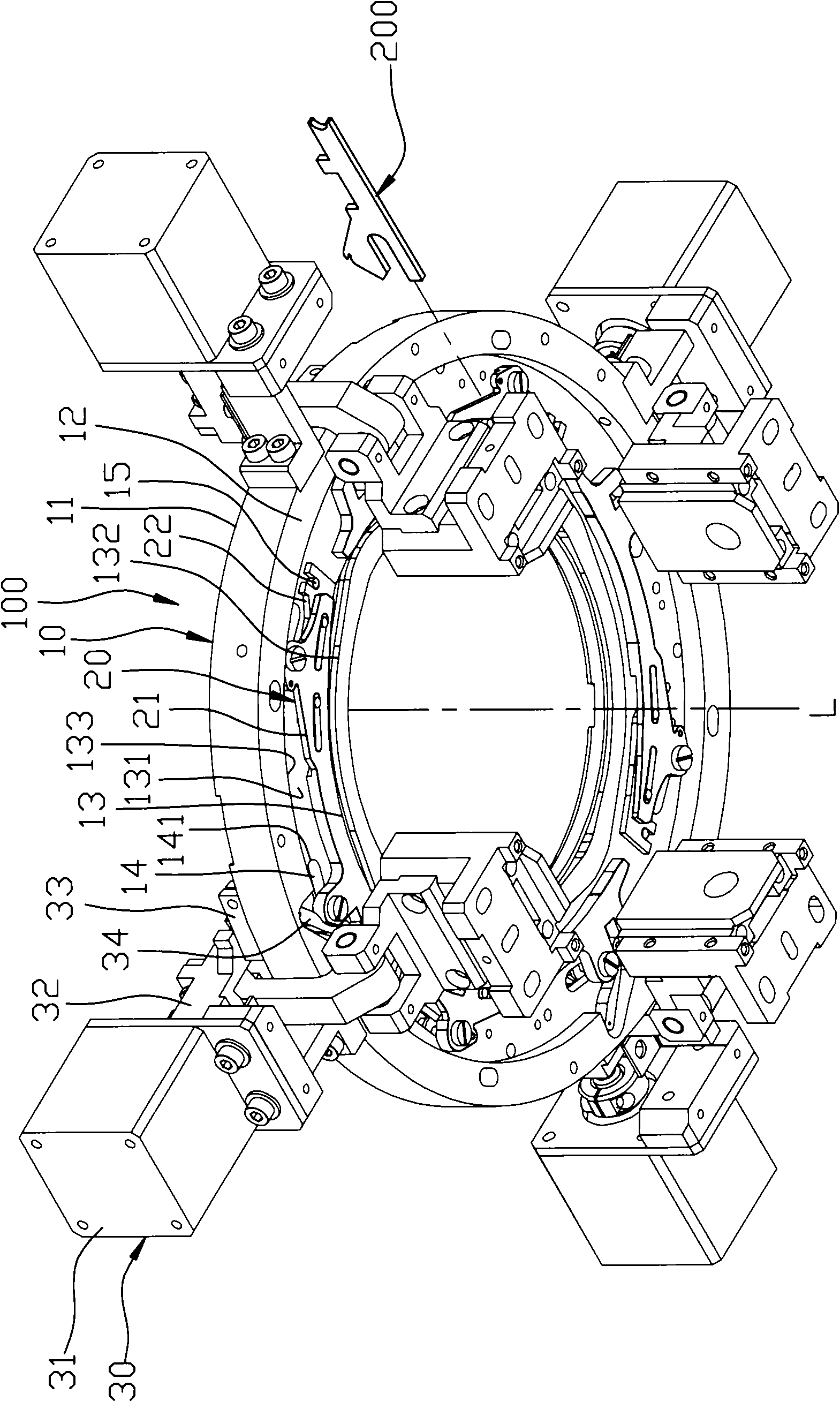

[0016] Such as figure 2 , image 3 and Figure 4 As shown, the preferred embodiment of the squeak control device of the sock knitting machine of the present invention, the control device 100 can provide multiple sacks 200 sleeves, and can control the movement stroke of the squeak 200, the control device 100 includes a Sink cover 10 , a plurality of control units 20 mounted on the Sink cover 10 , and a plurality of drive units 30 mounted on the Sink cover 10 and used to link the control units 20 .

[0017] The Sink cover 10 is hollow and ring-shaped, and has a top surface 11, a bottom surface 12 opposite to the top surface 11, a ring groove 13 formed by the bottom surface 12 and formed around an axis L, and a plurality of corresponding In the guide groove group 14 of the ring groove 13, the ring groove 13 is bounded by a groove bottom surface 131, an inner ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com