Wheel hub spinning machine

A spinning machine and wheel hub technology, applied in the field of wheel hub production equipment, can solve problems such as unloading, shaking, and bending of the rotating shaft, and achieve the effects of precise hydraulic cylinder stroke control, eliminating structural damage, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

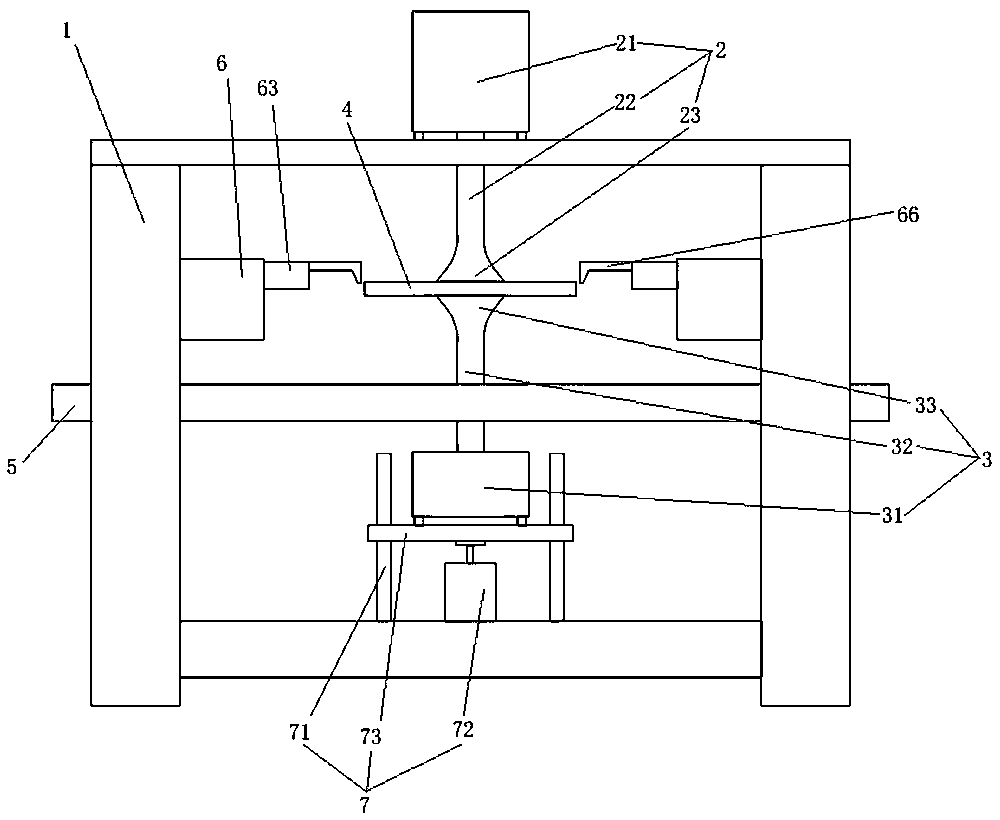

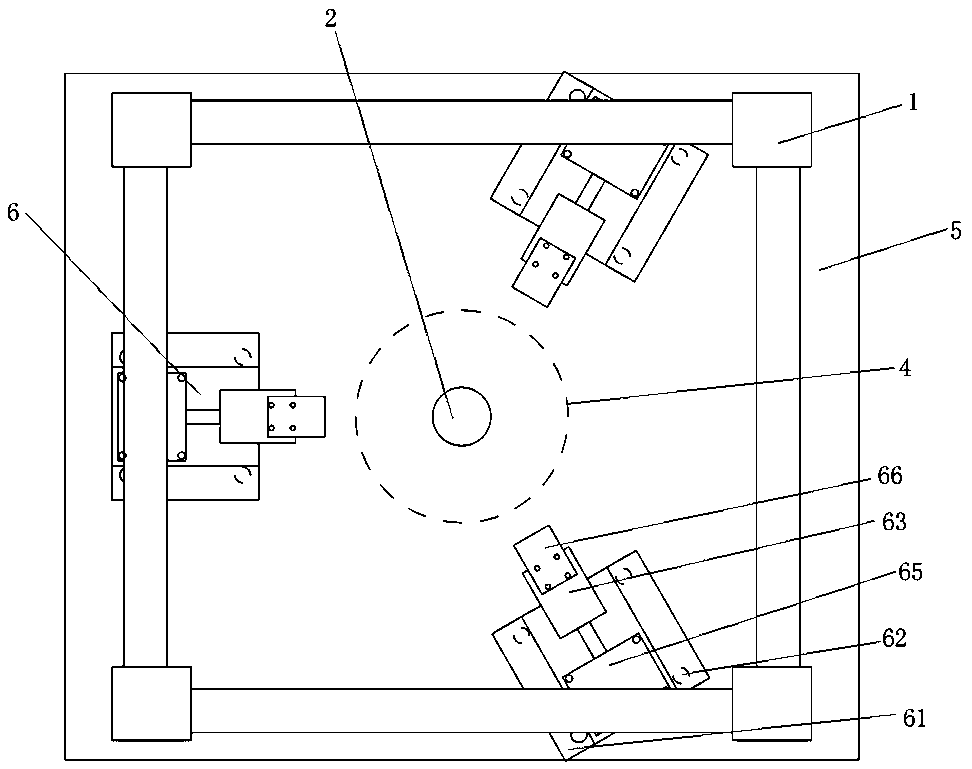

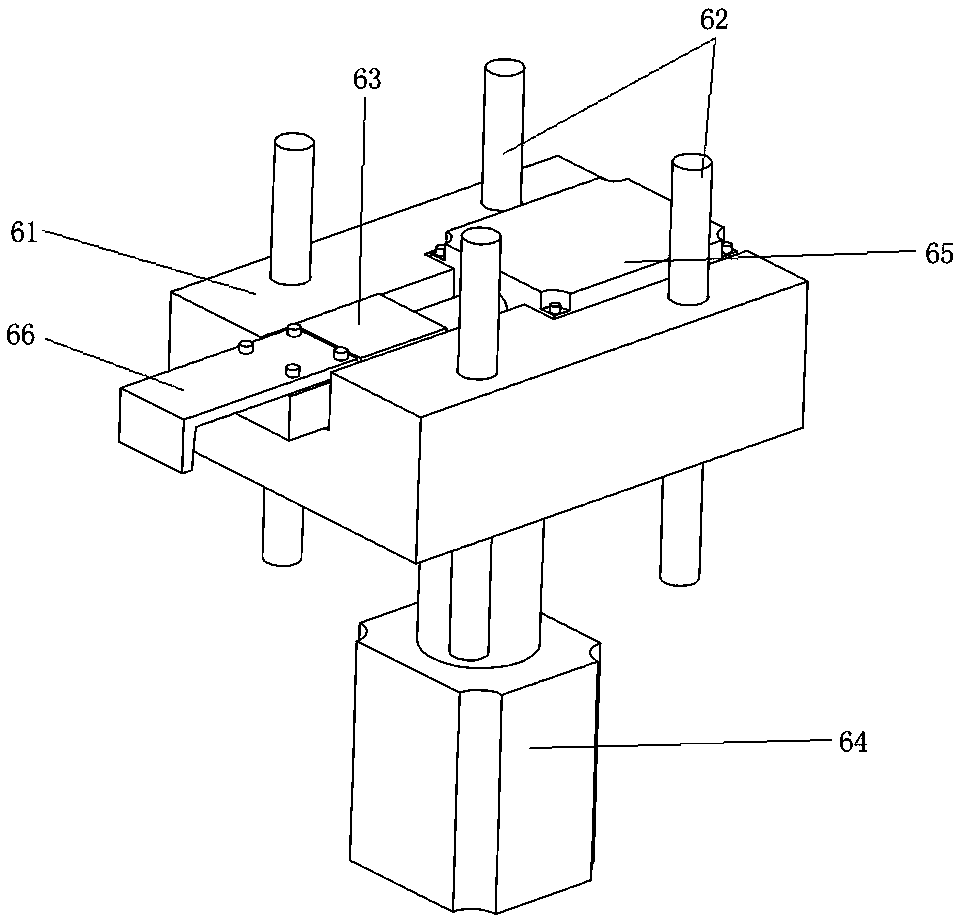

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

[0029] Such as figure 1 , 2 A wheel hub spinning machine shown in .3 includes a frame 1 in the form of a rectangular frame, a spindle module, and a spinning module 6. The spindle module includes the first vertically arranged upper and lower frame 1 for installing the wheel hub blank 4. A shaft group 2 and a second shaft group 3, the first shaft group 2 is longitudinally adjustable on the top plate of the frame 1, including a first servo motor 21 screwed to the top plate, connected to the output end of the first servo motor 21 And pass through the first shaft 22 extending downward from the top plate; the lower part of the frame 1 is equipped with a horizontally movable lower platform 7, and the second shaft group 3 is fixed on the lower platform 7, including screwed on the base plate 73 of the lower platform 7 The second servo motor 31 and the second shaft 32 connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com