Monitoring system of metal extrusion hydraulic press

A monitoring system and metal extrusion technology, applied in the field of hydraulic machinery, can solve problems affecting the monitoring of metal extrusion hydraulic presses, the inability to accurately control the speed, stroke and pressure of the press, and the impact on the precision control of hydraulic presses, so as to improve control accuracy and production. Efficiency, module reduction, and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

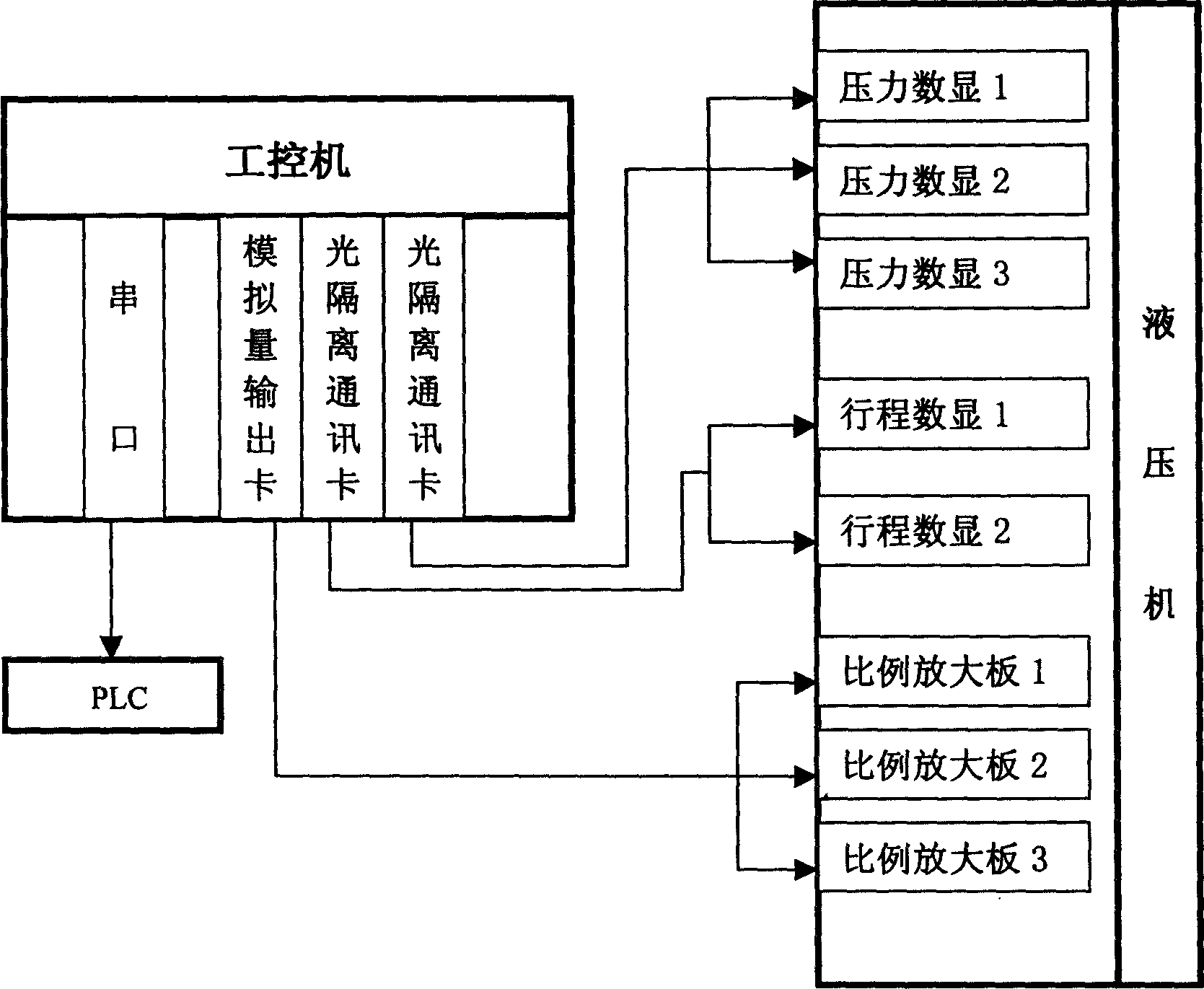

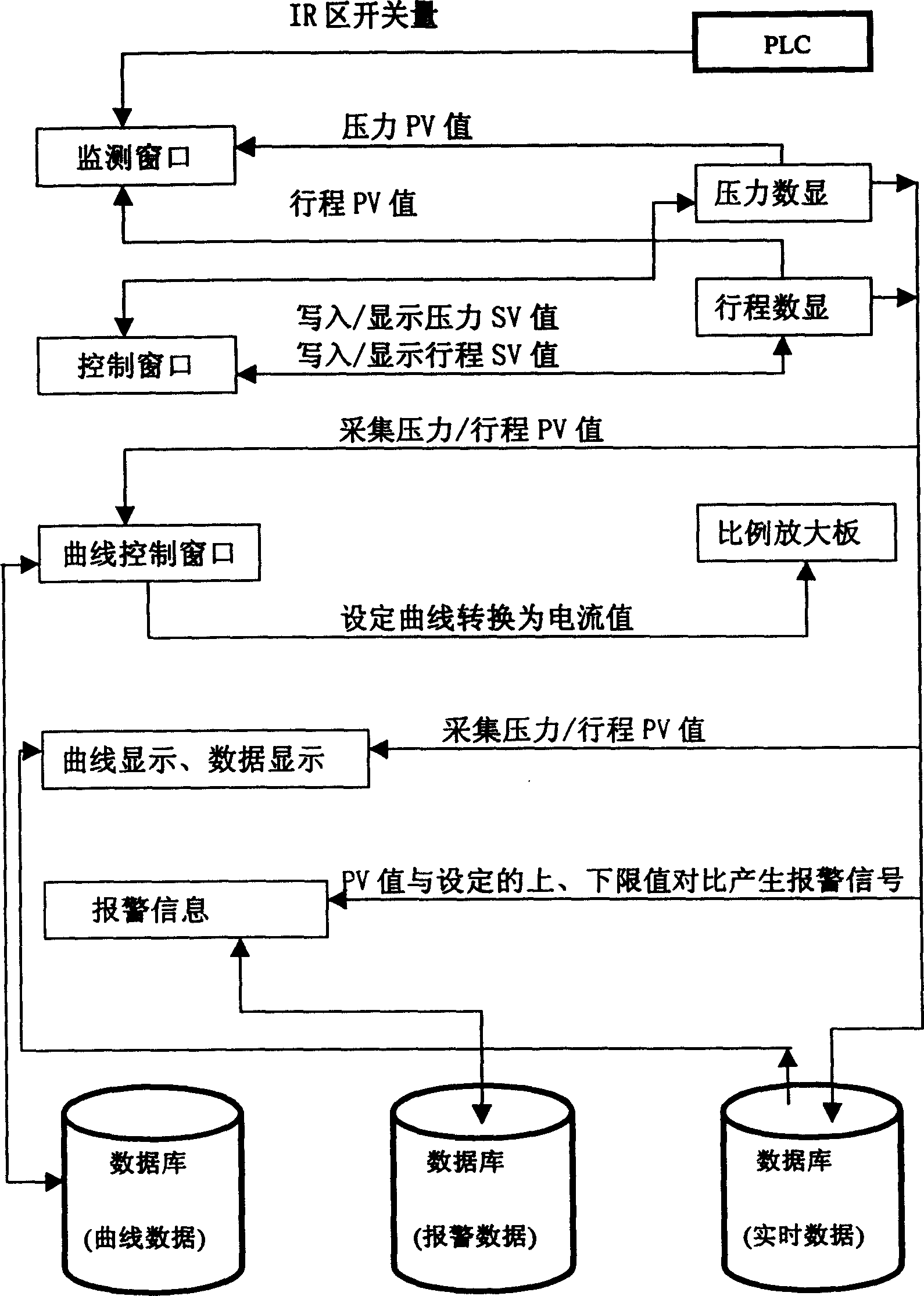

[0021] refer to figure 1 , figure 2 . The metal extrusion hydraulic press monitoring system, the connection between the industrial computer and the hydraulic press is shown in the figure. Insert the two optically isolated RS232 / 485 communication cards (Ci-132i) and Kangtuo analog output board (IPC5476B output 4 channels 4-20mA) into the main board of the industrial computer. The optically isolated communication card is set to the RS485 interface mode. The analog output board is set to output signal 4-20mA. Connect three pressure digital displays (SWP-C403-31-12-HL-P RS485 interface) that respectively display the slider pressure, feeding cylinder pressure, and ejector cylinder pressure in parallel to display the slider stroke and the eject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com