Concrete pump truck intelligent arm support control system and control method thereof

A technology for a concrete pump truck and a control system, which is applied in construction, building structure, and building material processing, etc., can solve problems such as inadequate control, low efficiency, and difficulty in control, and achieve improved pouring accuracy, accuracy and operation. The effect of ensuring the rationality of the hydraulic system and avoiding the influence of the life of the hydraulic system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] For ease of understanding the present invention, below in conjunction with following embodiment the present invention is further elaborated:

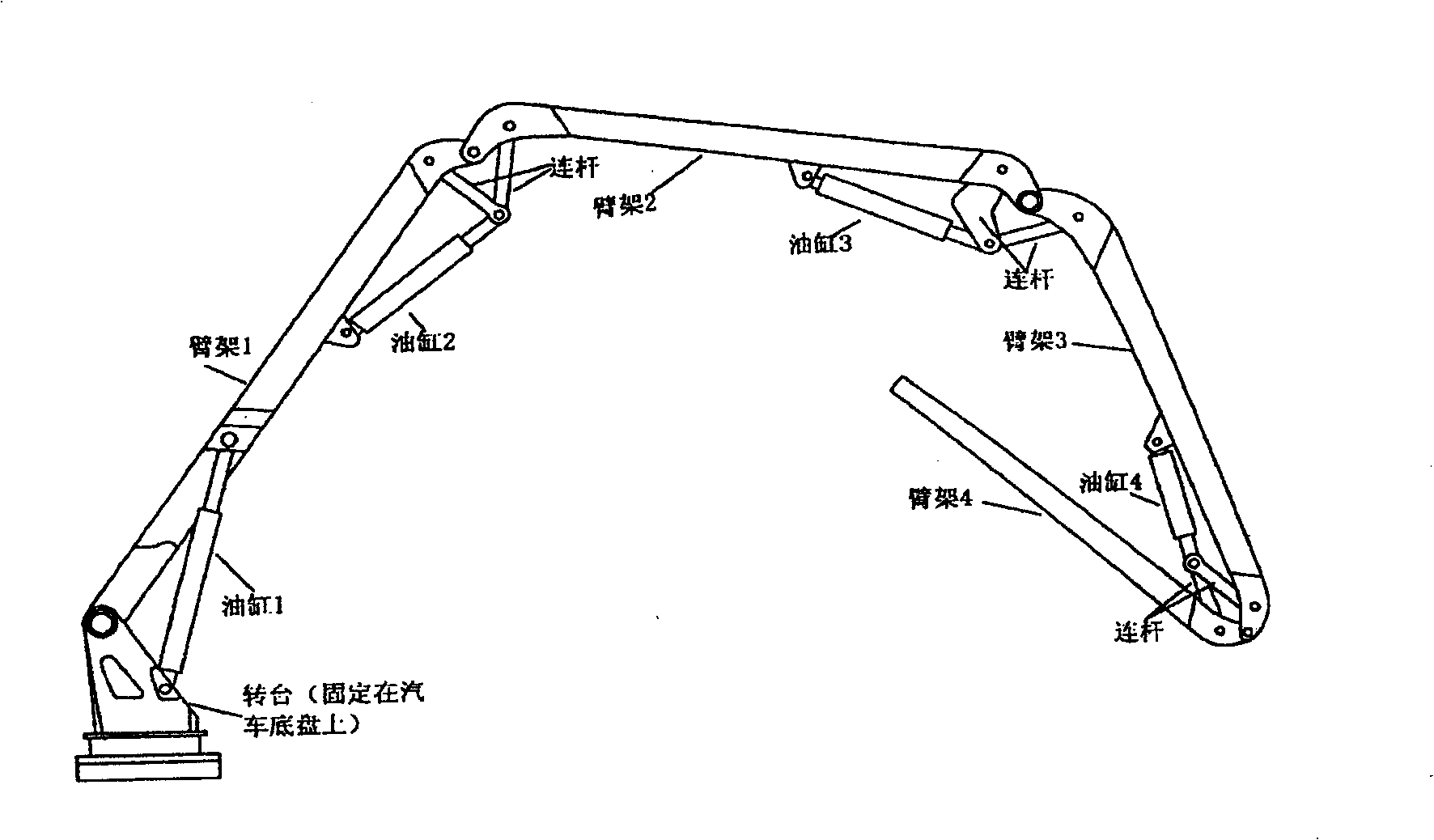

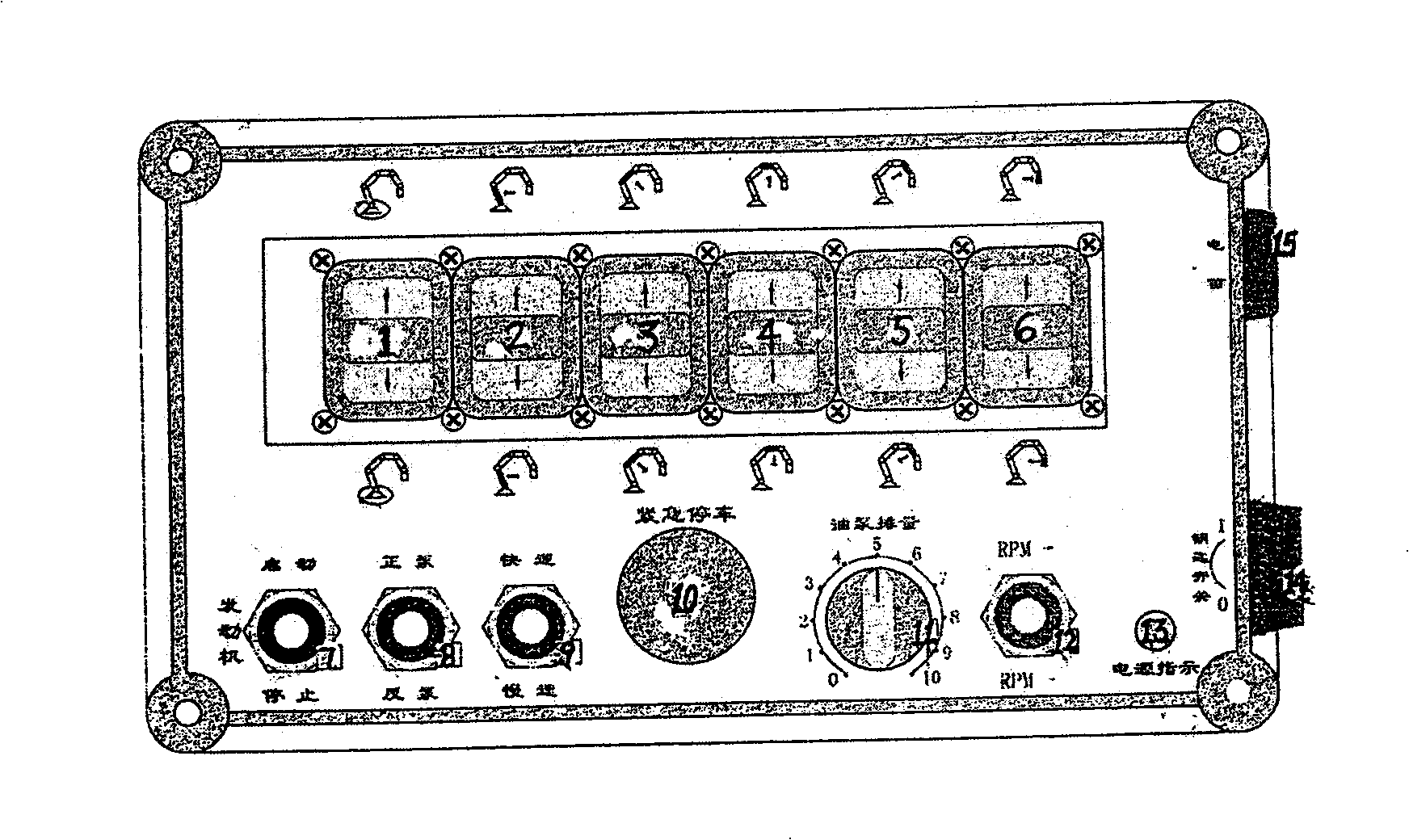

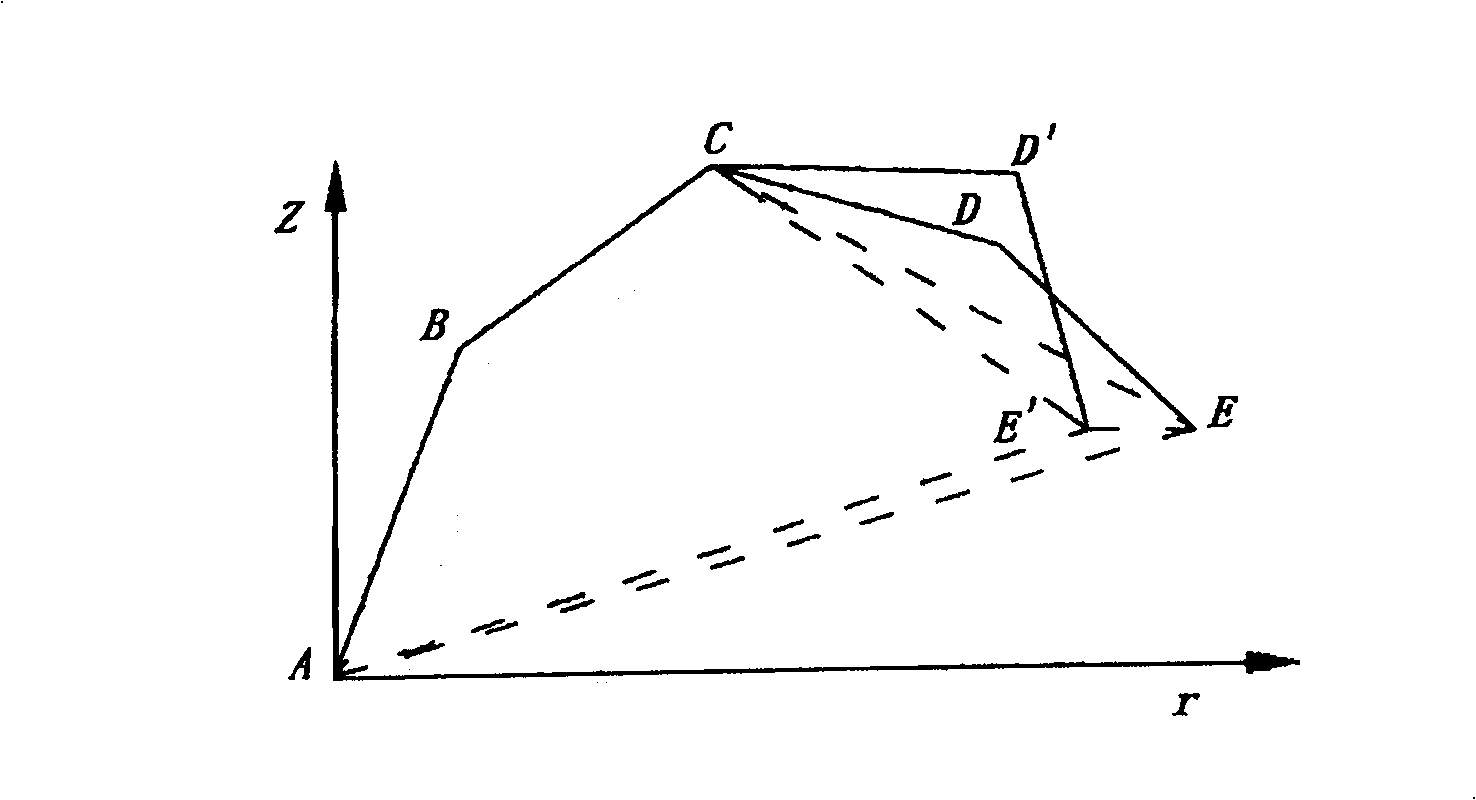

[0047] The core of the present invention is to realize the automatic combined action of each section of the boom and the slewing device through the detection feedback of the boom position signal and the control of the controller, so that the boom end material distribution device can easily move to the operator's expected position, and During the whole movement, keep the whole jib posture in a relatively reasonable state. Based on this kind of operation, the operator of the concrete pump truck does not need to manually adjust the position and rotation angle of a single boom section when performing the operation of pouring concrete, the accuracy of pouring and the rationality of the operation are guaranteed, and the construction efficiency and even the pump truck have a positive effect on the overall service life of the

[0048] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com