Control method, apparatus and system for concrete pump vehicle

The technology of a concrete pump truck and a control method, which is applied in the control field, can solve problems such as energy waste, and achieve the effect of avoiding waste and realizing energy-saving control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

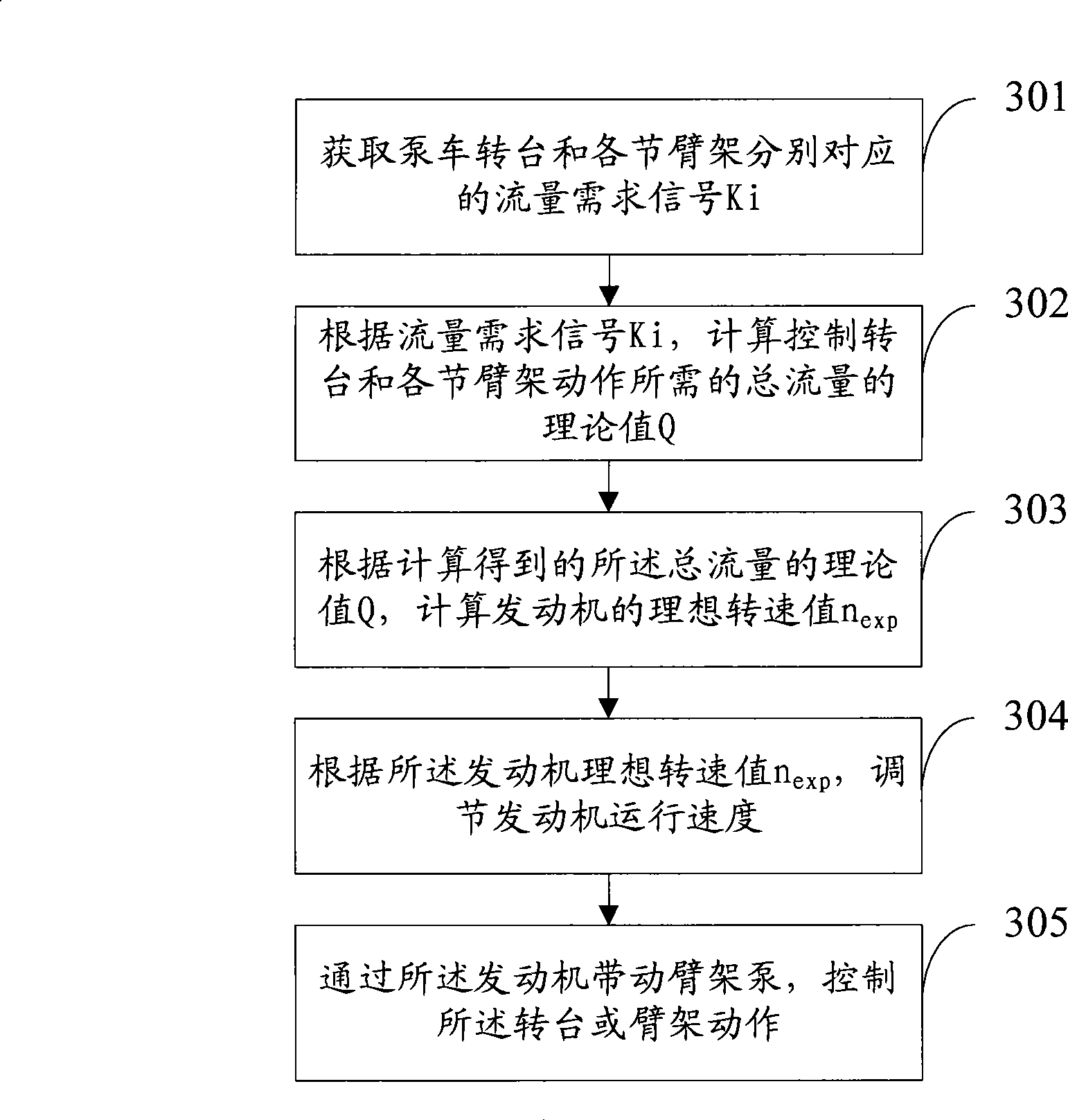

[0139] In the second embodiment, the push of the control handle corresponding to the turntable and each section of the jib is used as the flow demand signal as an example to describe in detail.

[0140] Assume that the flow rate required to control the movement of the turntable and each section of the jib is Qi (i=0, 1, 2, 3, 4). Then according to formula (1), we can get:

[0141] Qi=|Ki|×ARMi_Max_Flux (5)

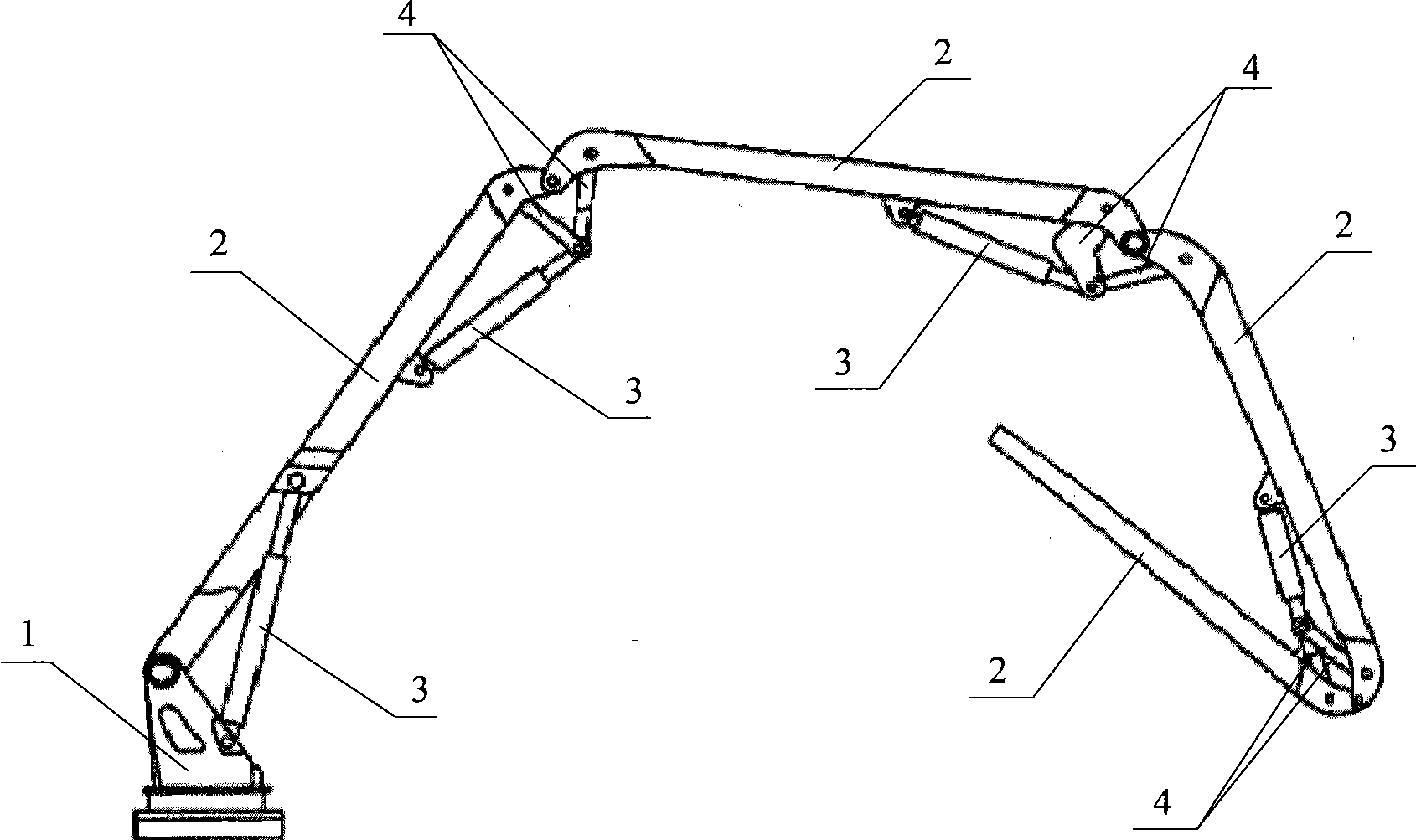

[0142] by figure 1 Take the four-boom pump truck as an example:

[0143] The flow value required to control the movement of the turntable is: Q0=|K0|×ARM0_Max_Flux.

[0144] The flow value required to control the movement of 1# boom is: Q1=|K1|×ARM1_Max_Flux.

[0145] Step 407: Calculate the current value Ii required to control the action of the proportional valve corresponding to the turntable and each boom according to the flow value Qi required to control the movement of the turntable and each boom.

[0146] According to the flow control curve of the proportional v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com