Mortar transfer device

A transfer device and mortar technology, which is used in transportation and packaging, clay preparation devices, cement mixing devices, etc., can solve the problems of inability to guarantee fluidity and quality, labor-intensive operators, and difficulty in finding living grids, and reduce costs. and weight, good perfusion quality and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

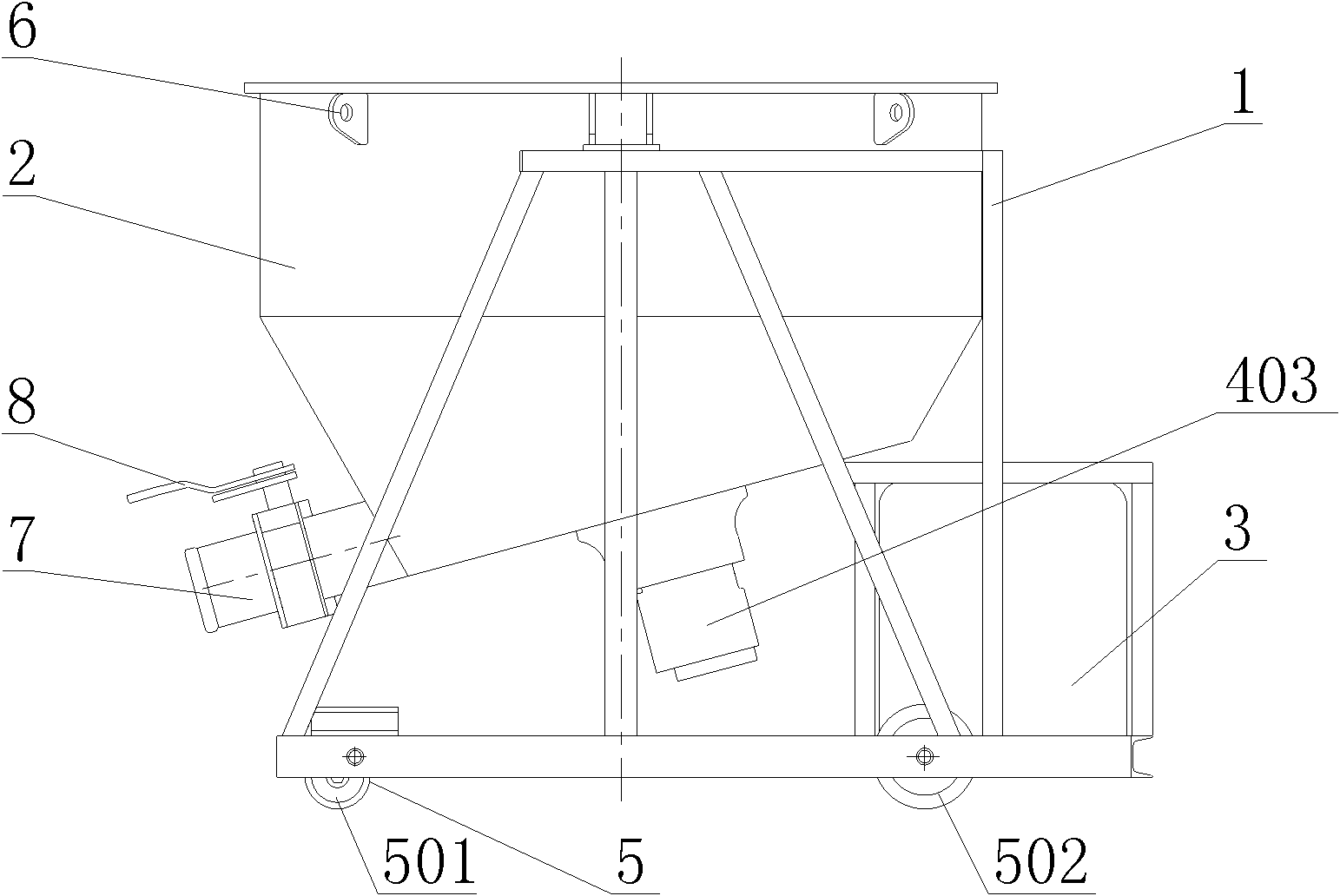

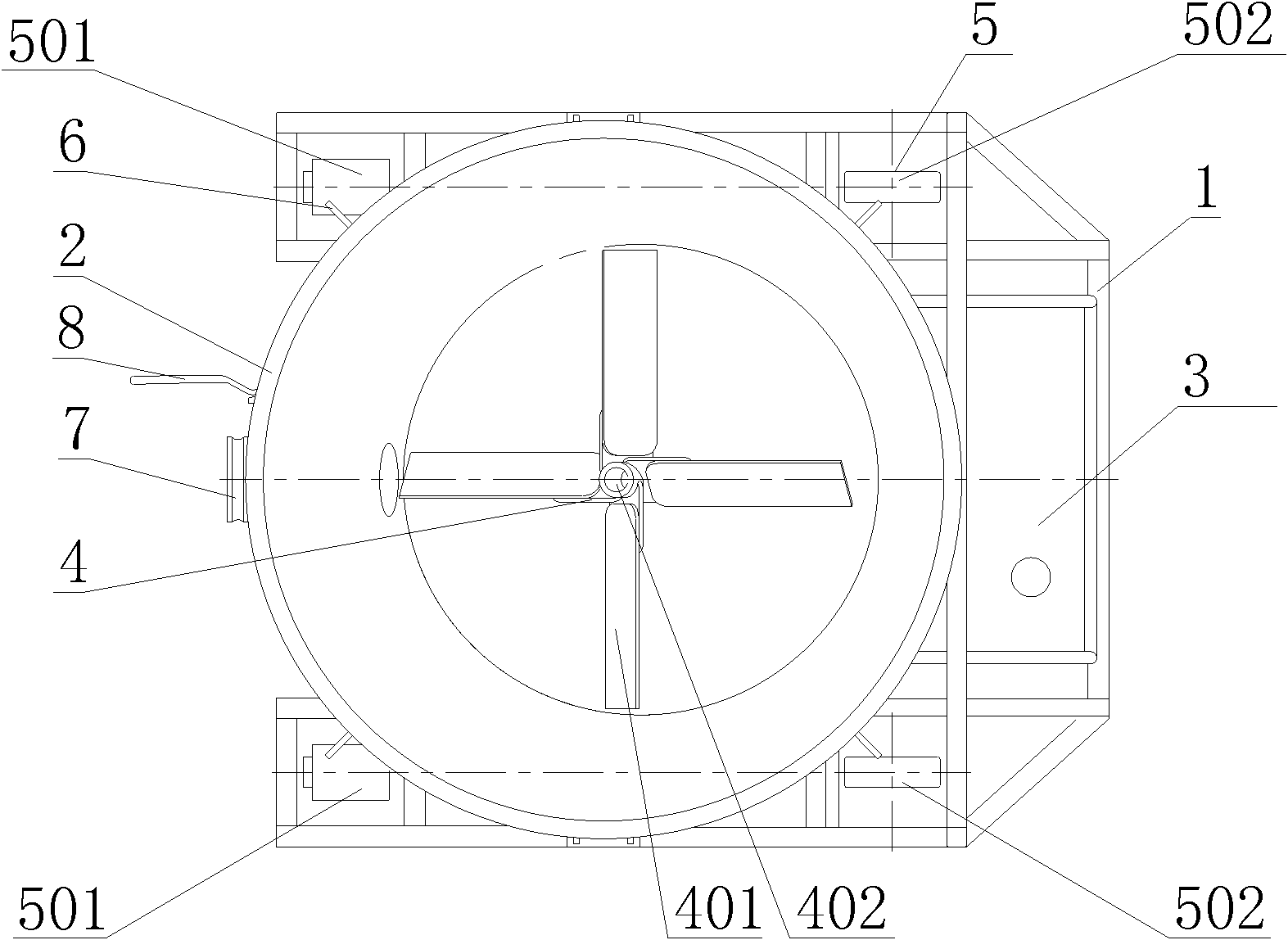

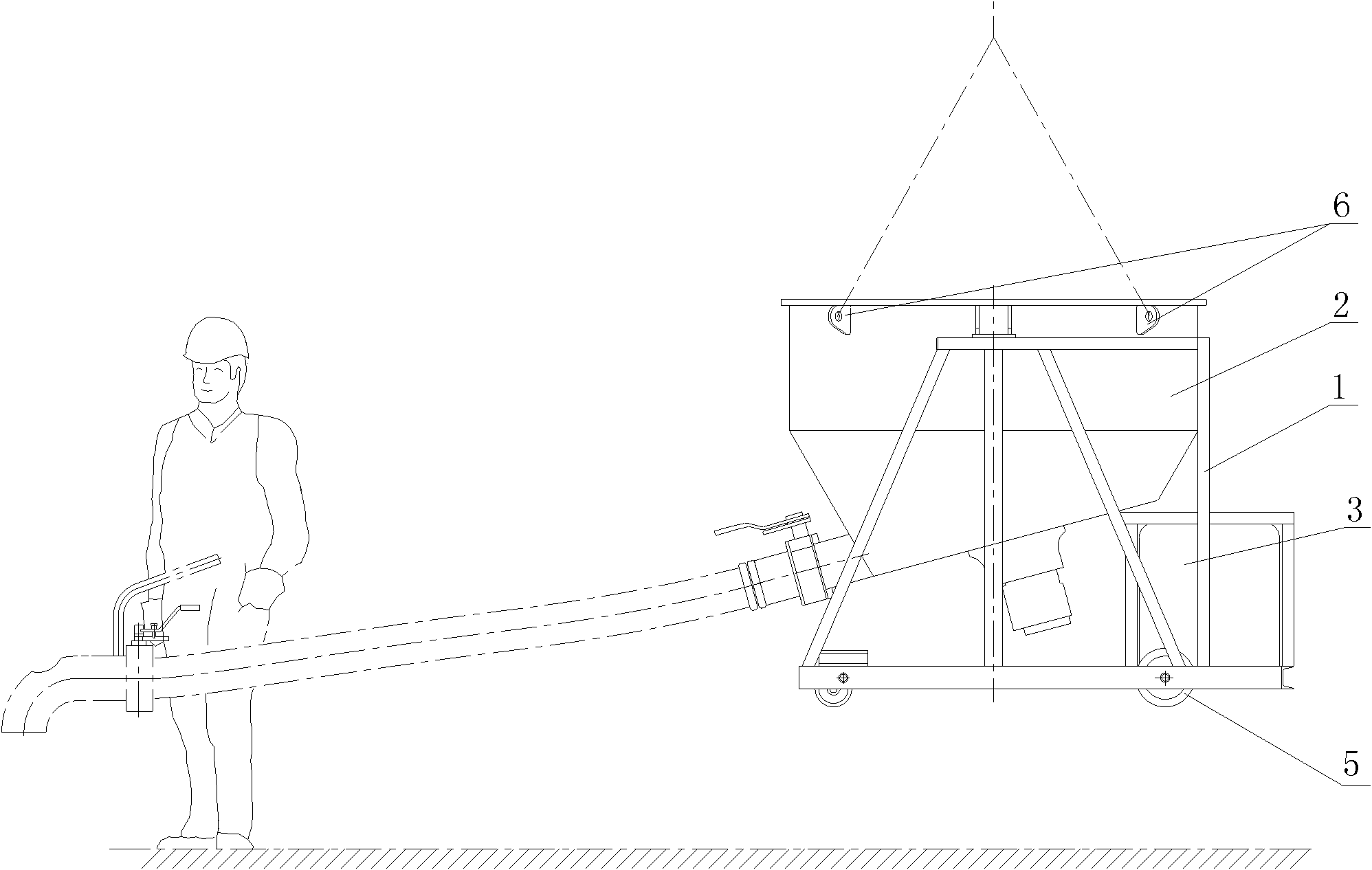

[0022] like figure 1 and figure 2 As shown, a mortar transfer device includes a frame 1 and a hopper 2 fixed on the frame 1, the hopper 2 is provided with a self-stirring assembly 4, and the self-stirring assembly 4 includes an agitating shaft 402, a hopper fixed on the agitating shaft 402 The stirring blade 401 and the motor 403 , the stirring shaft 402 are connected to the output end of the motor 403 , and the motor 403 is connected to the power supply assembly 3 installed on the frame 1 .

[0023] During the transfer process, the power supply component 3 drives the motor 403 to rotate, so that the stirring blade 401 continuously stirs the mortar in the hopper 2, which can prevent the fluidity loss of the mortar and the decrease of the air volume, and can ensure the quality of the finished mortar. The structure of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com