Preparation and application of two-component self-compacting concrete for slab ballastless track

A technology of self-compacting concrete and slab ballastless track, which is applied to clay preparation devices, cement mixing devices, chemical instruments and methods, etc., and can solve problems such as low measurement accuracy, large loss in the construction process, and uncontrollable working performance of the mixture , to achieve the effect of green and environmental protection construction, simple construction procedures and improved controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

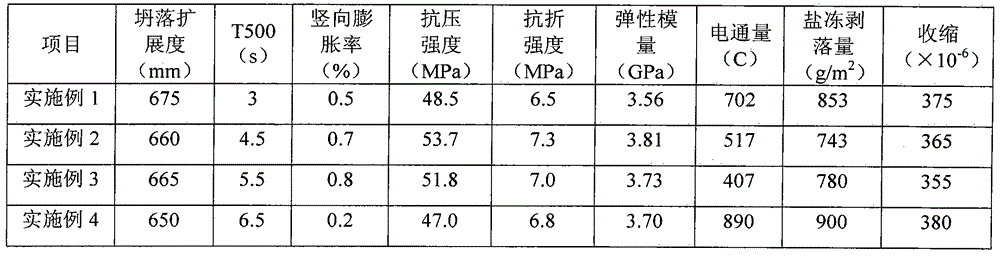

Examples

Embodiment 1

[0038] The raw materials of the dry mixture for two-component self-compacting concrete are weighed according to the following proportions:

[0039] Gelling components: ordinary portland cement: 70 parts, fly ash: 20 parts, finely ground slag powder: 10 parts

[0040] River sand with fineness modulus 2.5: 320 parts

[0041] 5-10mm coarse aggregate: 250 parts

[0042] Bulking component: 11 parts

[0043] The raw materials of the liquid material for two-component self-compacting concrete are weighed according to the following proportions:

[0044] Water: 100 parts

[0045] Polycarboxylate water reducer: 1 part

[0046] Viscosity adjustment component: 3 parts

[0047] Accurately weigh the two materials according to the dry mix: liquid material ratio of 1:0.12, first add the dry mix to the mixer, and stir for 1 min. During the mixing process, add the weighed liquid material into the mixer, and then stir until the The self-compacting concrete is mixed evenly, and the mixing ti...

Embodiment 2

[0050] The raw materials of the dry mixture for two-component self-compacting concrete are weighed according to the following proportions:

[0051] Gelling components: ordinary portland cement: 60 parts, fly ash: 35 parts, silica fume: 5 parts

[0052] Inert mineral admixture: Granite stone powder: 22 parts

[0053] Fineness modulus 2.7 granite machine-made sand: 350 parts

[0054] 5-20mm coarse aggregate: 300 parts

[0055] Polycarboxylate water reducer: 2 parts

[0056] Bulking component: 16 parts

[0057] Viscosity adjustment components: 6 parts

[0058] The raw materials of the liquid material for two-component self-compacting concrete are weighed according to the following proportions:

[0059] Water: 100 parts

[0060] Accurately weigh the two materials according to the dry mix: liquid material ratio of 1:0.13, first add the dry mix to the mixer, and stir for 1 min. During the mixing process, add the weighed liquid material into the mixer, and then stir until the ...

Embodiment 3

[0063] The raw materials of the dry mixture for two-component self-compacting concrete are weighed according to the following proportions:

[0064] Gelling components: ordinary portland cement: 76 parts, fly ash: 20 parts, metakaolin: 4 parts

[0065] Inert mineral admixture: basalt rock powder: 18 parts

[0066] Fineness modulus 2.7 artificial sand: 280 parts

[0067] 5-16mm coarse aggregate: 200 parts

[0068] Polycarboxylate water-reducing and slump-retaining components: 2 parts

[0069] Bulking component: 20 parts

[0070] The raw materials of the liquid material for two-component self-compacting concrete are weighed according to the following proportions:

[0071] Water: 100 parts

[0072] Viscosity adjustment component: 3 parts

[0073] Accurately weigh the two materials according to the dry mix: liquid material ratio of 1:0.13, first add the dry mix to the mixer, and stir for 1 min. During the mixing process, add the weighed liquid material into the mixer, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com