Double-pipe underwater concrete pouring method for super-large-diameter pressure-bearing piles

An underwater concrete and ultra-large diameter technology, which is applied in construction, infrastructure engineering, etc., can solve the problems of inability to guarantee the quality of pile foundations, concrete performance cannot ensure that the primary pouring concrete extends to cover the entire pile bottom, and cannot meet the requirements of primary pouring concrete specifications, etc. problems, to achieve the effect of reducing structural strength and capacity requirements, good economic benefits and social effects, and high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

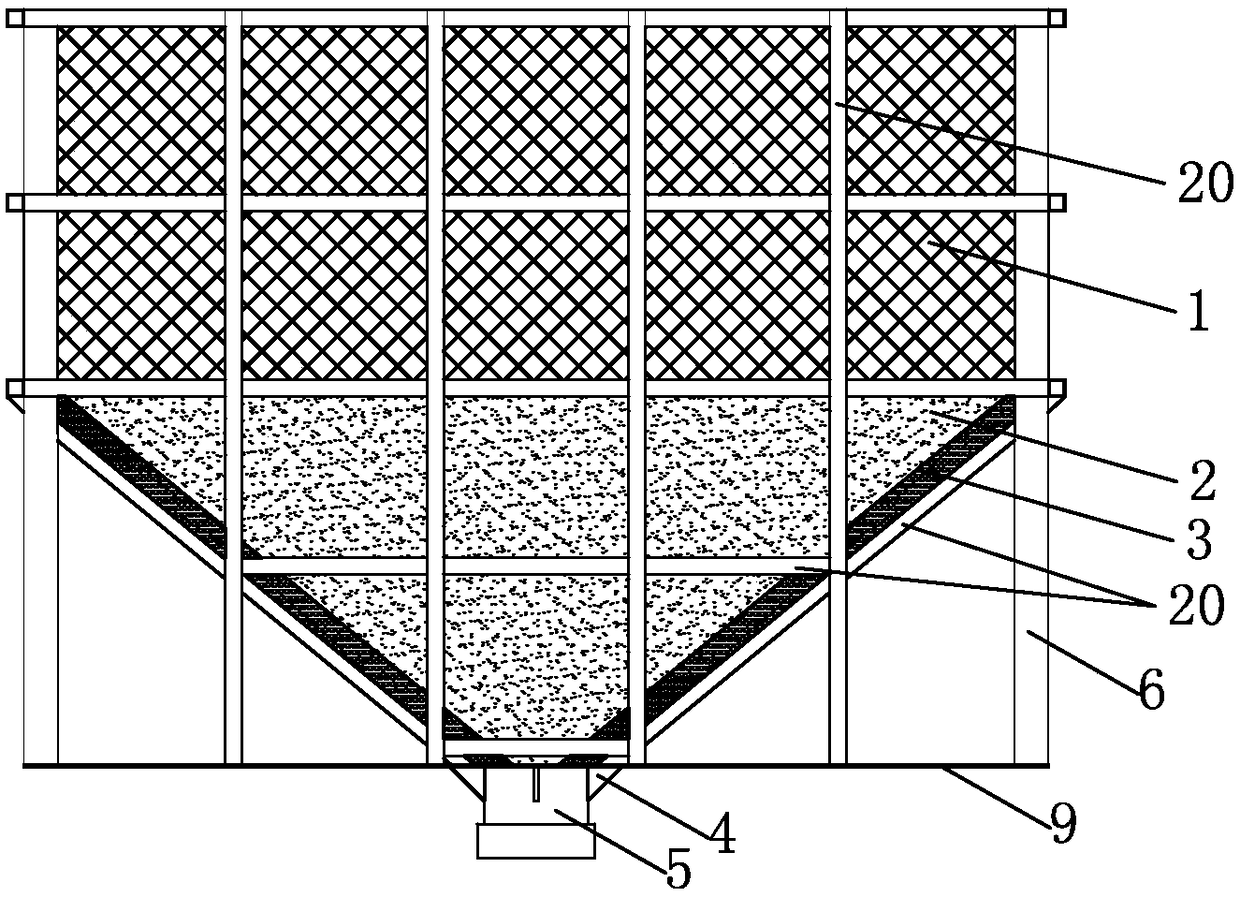

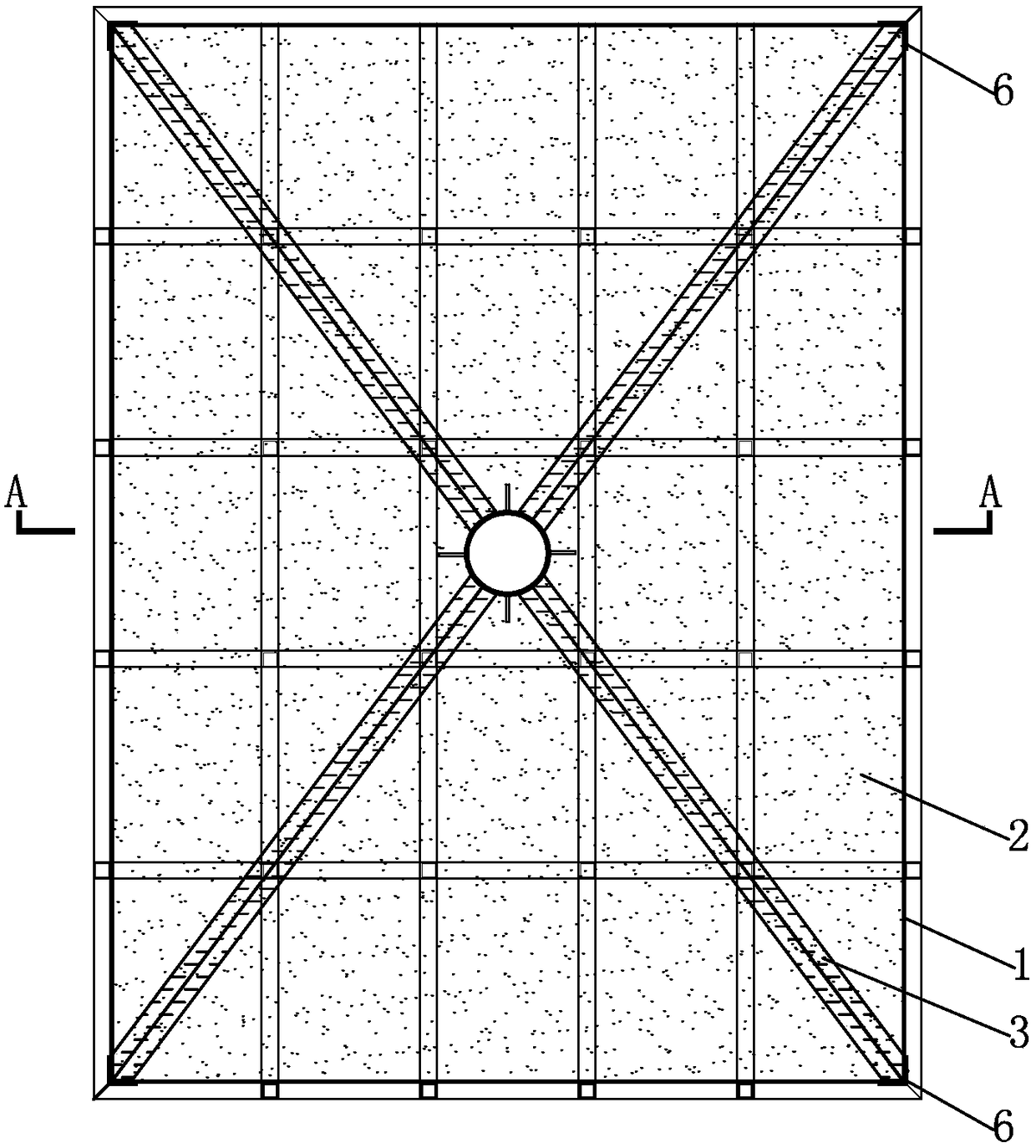

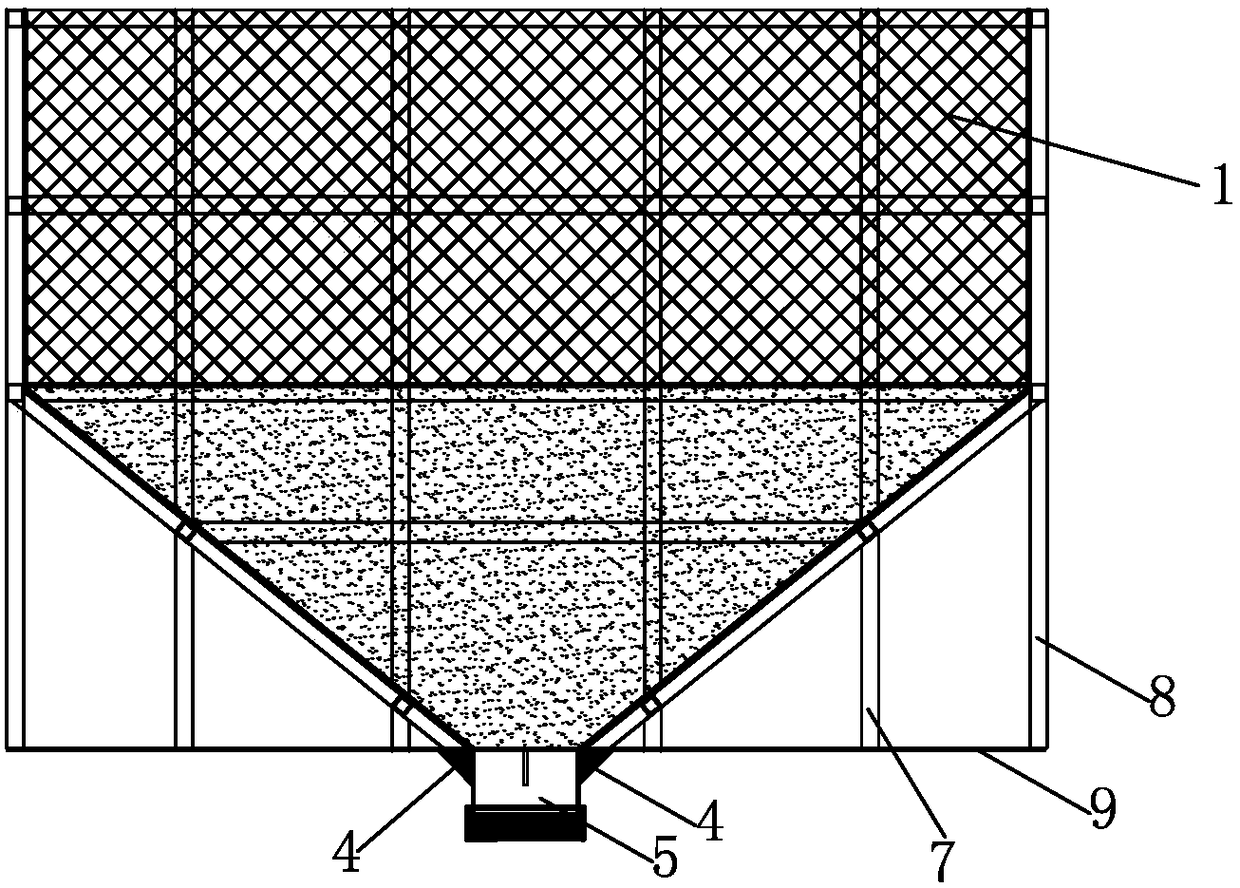

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0024] A double-pipe underwater concrete pouring method for super-large-diameter pressure-bearing piles is characterized in that it includes the following steps:

[0025] Step a: develop a type of underwater self-compacting concrete, as shown in Table 1, the formula of the underwater self-compacting concrete is water, cement, Class II pulverized coal, S95 mineral powder, silica fume, machine-made sand, natural sand, 0- 1 gravel, 132 gravel and admixture, every 1m 3 Self-compacting concrete contains 160kg of water, 270kg of cement, 100kg of grade II pulverized coal, 80kg of S95 mineral powder, 15kg of silica fume, 840kg of machine-made sand, 100kg of natural sand, 260kg of 0-1 crushed stone, 600kg of 132 crushed stone, and 24.3kg of admixture ; The underwater self-compacting concrete prepared by the above formula has a slump of 280mm, a degree of expansion of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| loss on ignition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com