Underwater grouting equipment for large-volume cavity

An underwater grouting and large-volume technology, which is applied in hydropower, construction, infrastructure engineering, etc., can solve the problems of secondary gaps, failure to consider, and slurry escape, so as to prevent slurry backflow and improve perfusion quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

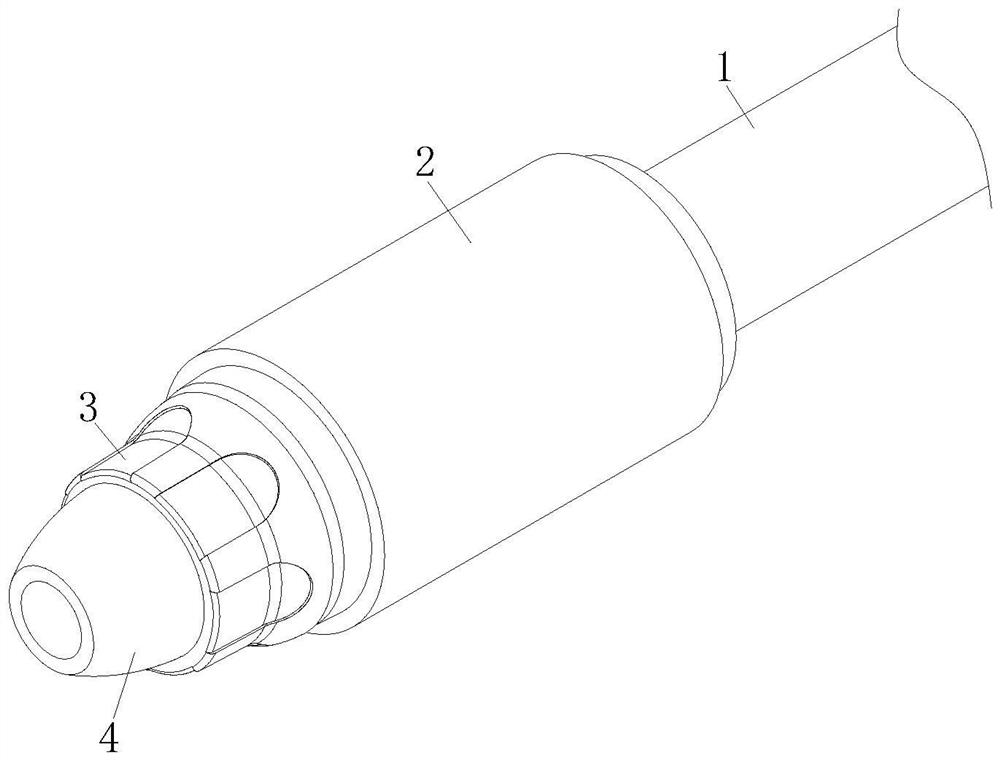

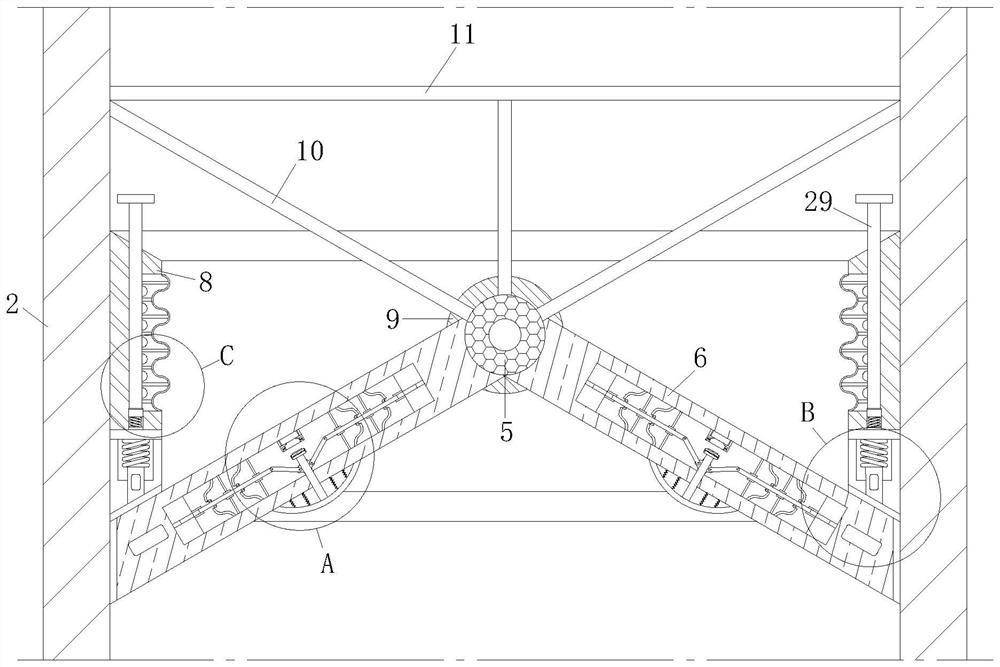

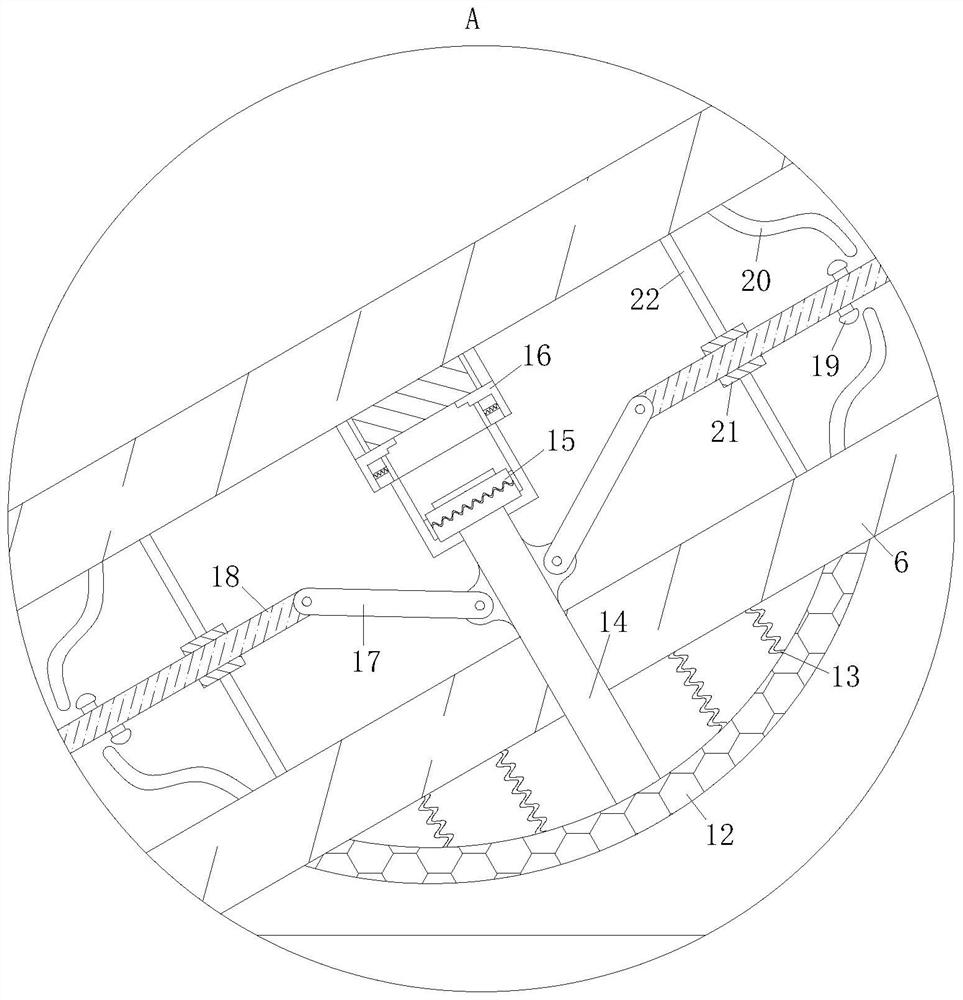

[0040] Example 1. A kind of underwater grouting equipment for large volume cavity, composition such as Figure 1-4 Shown, comprising a grouting tube 1, the grouting tube 1 end is connected to a fully automatic dust-free mixer, the grouting tube 1 at the other end of the socket is connected to the stop housing 2, the stop housing 2 away from the grouting tube 1 end of the socket 3, the connection ring 3 away from the check case 2 end of the socket is connected to the nozzle 4, the stop housing body 2 is fixed inside the support pin 5, the support pin 5 is provided externally with two separators 6, the two of the separator plate 6 is hinged by a torsion spring on the outside of the support pin 5, The baffle 6 is fixed with a rubber plate 7 at one end away from the support pin 5, the plywood 7 is connected to the inner wall of the stop housing 2 sliding connection; when working, the slurry is injected into the grout pipe 1, and then the slurry will be injected into the cavity through ...

Embodiment 2

[0049] Example 2, an underwater grouting apparatus for a large volume cavity, constitutes such as Figure 5 As shown, compared to Example 1, using another embodiment, the difference is that the limit ring 8 is connected internally with a reciprocating rod 29, the bottom end of the reciprocating rod 29 is fixed with a vibration spring 30, the reciprocating rod 29 is fixed to the transmission block 31 near the center of the check housing 2, the transmission block 31 away from the reciprocating rod 29 on one side is provided with a wave rod 32, the wave rod 32 away from the reciprocating rod 29 at one end fixed with a wave housing 33, the wave housing 33 is fixed to the limit ring 8 fixed connection When working, when the slurry is perfused, it will also collide with the reciprocating rod 29, and the impact force will act on the vibration spring 30 through the reciprocating rod 29, thereby causing the reciprocating flutter of the vibration spring 30, and the reciprocating rod 29 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com