Pouring mold and pouring process for light-weight aggregate concrete PC component

A technology of lightweight aggregate concrete and components, applied in molds, manufacturing tools, ceramic molding machines, etc., can solve the problems of aggregate floating, inability to guarantee pouring quality, segregation of coarse and fine aggregates, etc., and achieve ease of floating, easy separation, and distribution uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

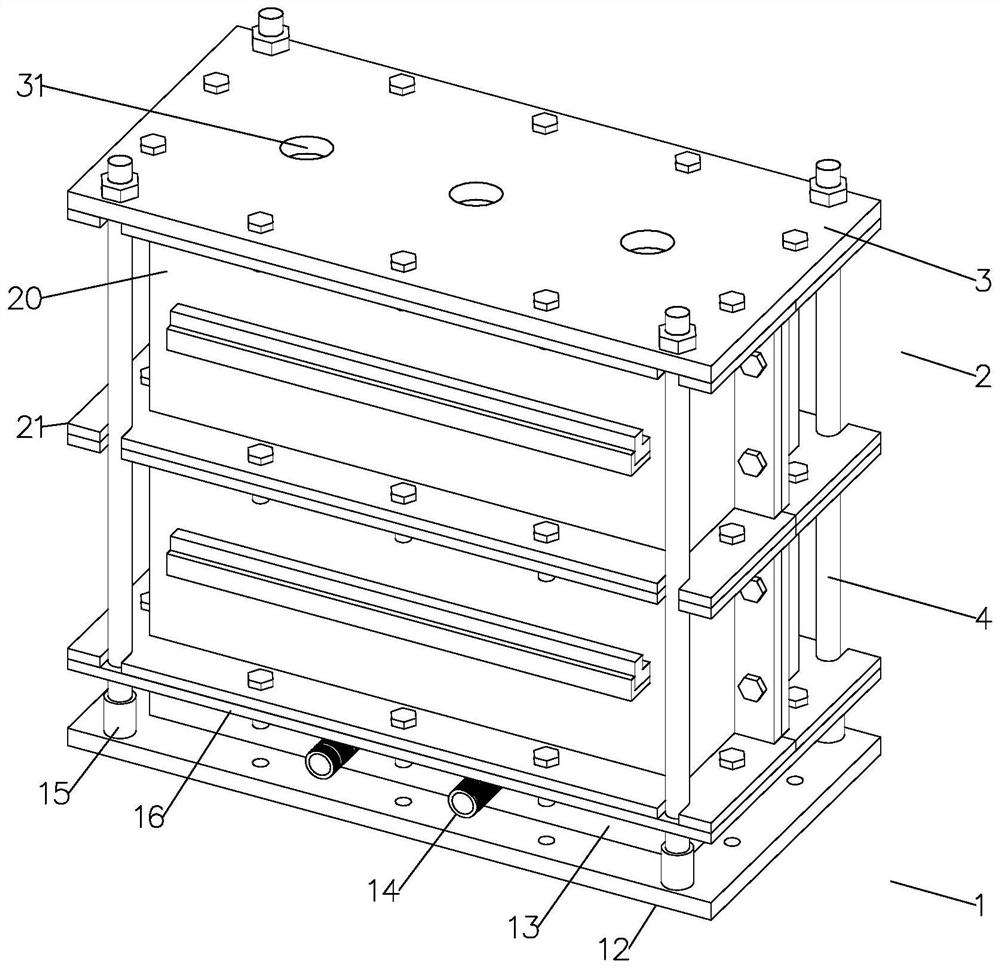

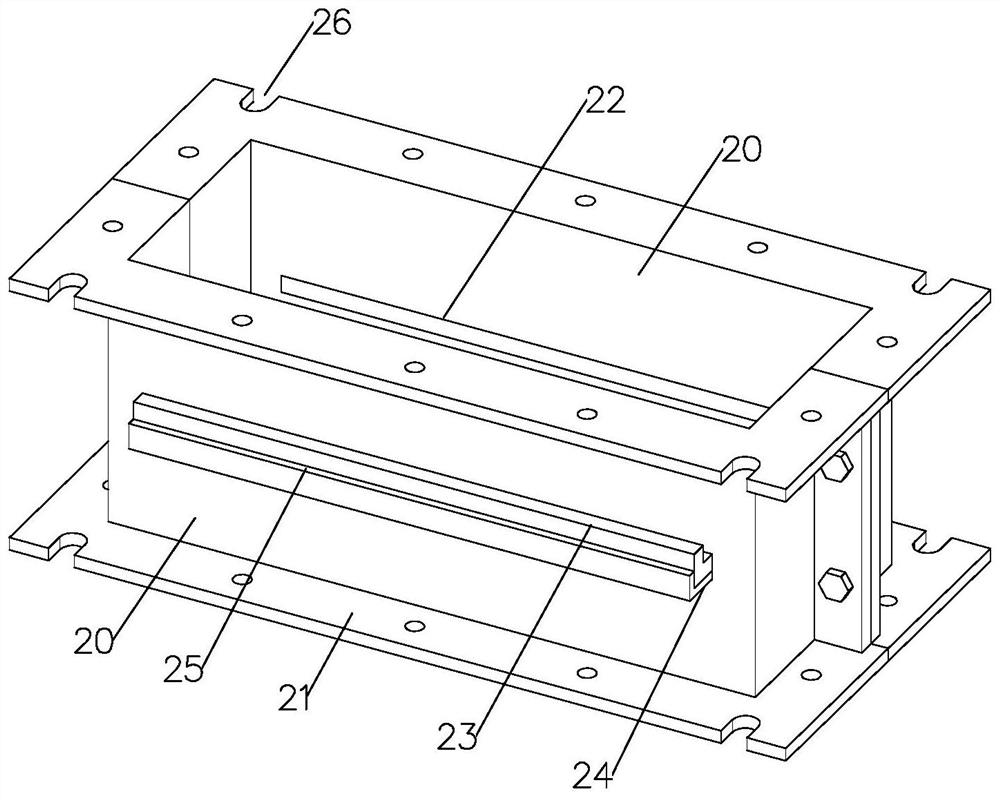

[0049] The following is attached Figure 1-4 The application is described in further detail.

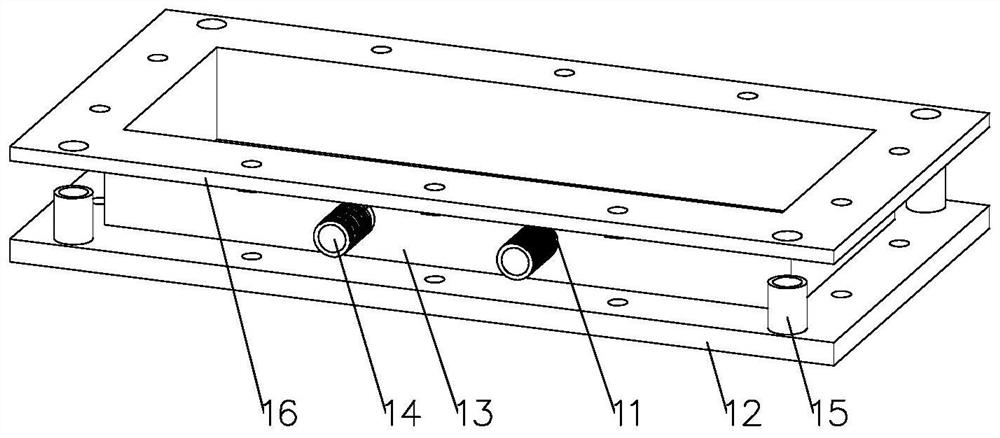

[0050] The embodiment of the present application discloses a light aggregate concrete PC component pouring mold. refer to figure 1 with 2 , the perfusion mold includes a bottom mold 1 with an upper opening, and the bottom mold 1 includes a bottom plate 12 and a frame plate 13. In this embodiment, the lightweight aggregate concrete prefabricated component is set as a rectangular strip member, and the bottom plate 12 is set as a rectangular flat plate, which can be passed through The pre-embedded anchor bolts are fixed on the working ground, the frame plate 13 is set as a rectangular frame, and its four side plates are vertically welded and fixed on the bottom plate 12 .

[0051]Two grouting interfaces 11 are provided on one long side plate of the frame plate 13, the grouting interfaces 11 are arranged as circular holes, the hole walls are provided with threads, and the grouting int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com