Integrated perfusion assembly line for wind turbine blade and perfusion process thereof

A wind power generation blade and assembly line technology, which can be applied to other household appliances, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as high resin viscosity, long infusion time, and impact on infusion quality, so as to reduce equipment costs, Save labor costs and improve perfusion quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific examples.

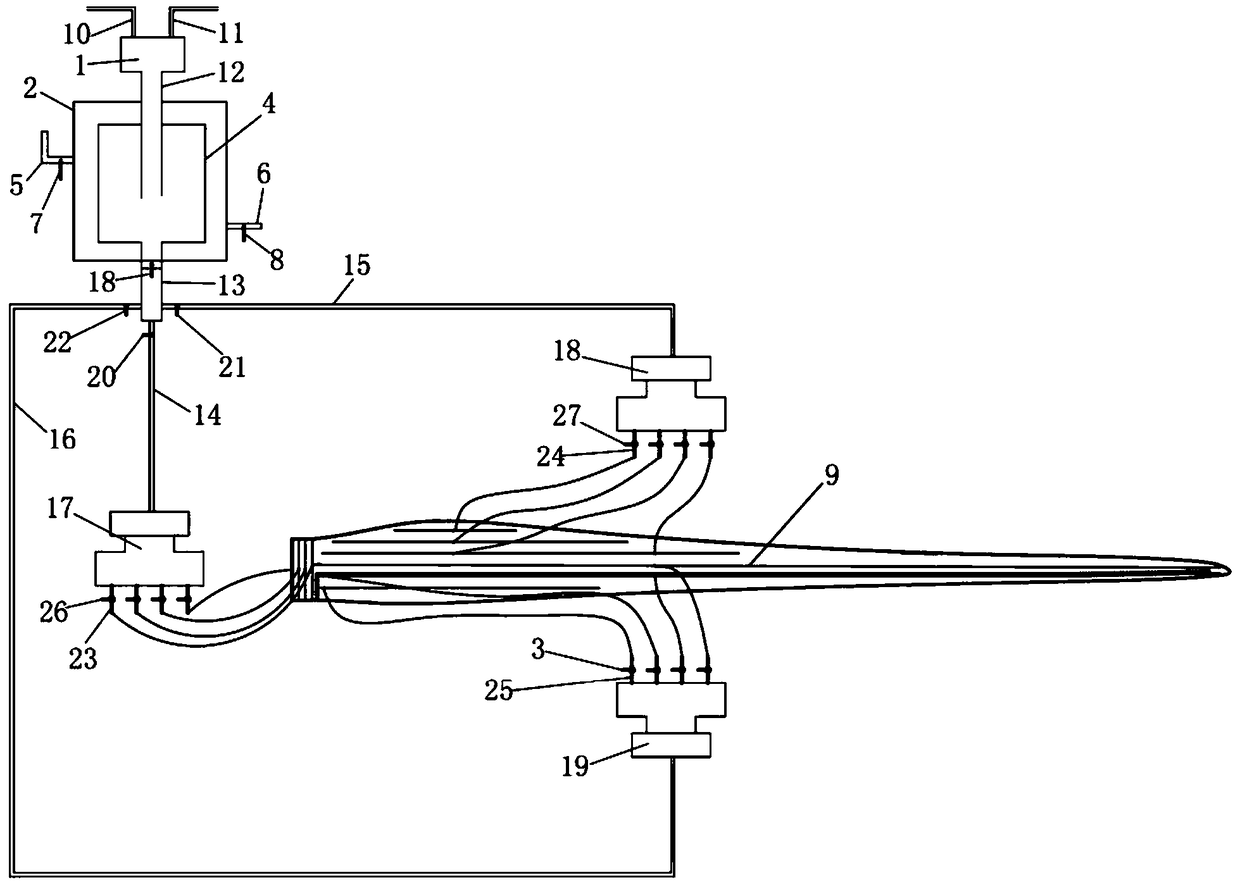

[0043] see figure 1 As shown, the integrated infusion line for wind power generation blades provided in this embodiment includes a resin mixing bin 1, a resin mixing and degassing integrated box 2, and an infusion storage bin, wherein the resin mixing and degassing integrated box 1 An ultrasonic chamber 4 is provided, and the outer wall of the resin mixing and degassing integrated box 1 has a heating or cooling function, and an air release pipe 5 and an air extraction pipe 6 are installed respectively, and an air release port valve 7 is installed on the air release pipe 5 , the pumping pipe 6 is equipped with a pumping port valve 8 and can be externally connected to a vacuum pump, and the resin mixing chamber 1 is respectively equipped with a resin A component feeding pipe 10 and a resin B component feeding pipe 11, and the resin mixing The warehouse 1 communicates with the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com