Efficient thixotropic agent for tunnel lining concrete and preparation method of efficient thixotropic agent

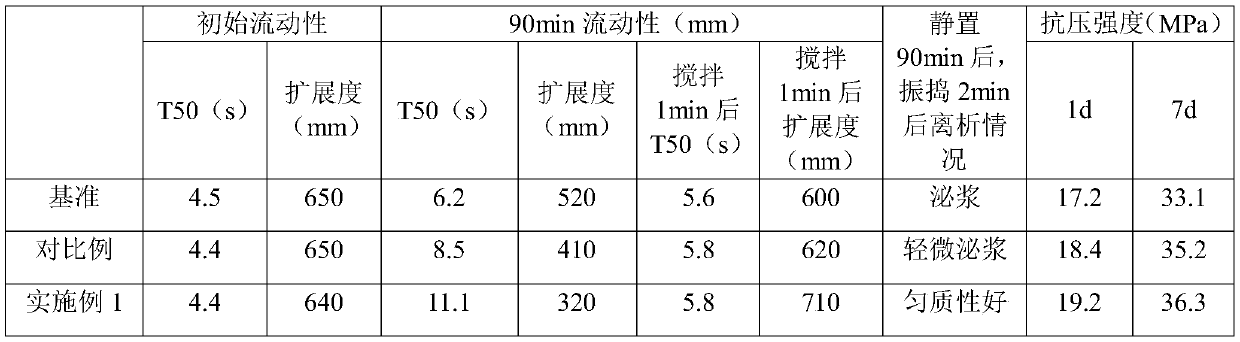

A thixotropic agent and concrete masonry technology, which is applied in the field of building materials, can solve the problems of limited thixotropic effect of high-fluidity concrete, loss of concrete thixotropic effect over time, and large fluctuations in concrete work performance, etc., to achieve thixotropic function Good retention, improved injection efficiency and perfusion quality, and excellent fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

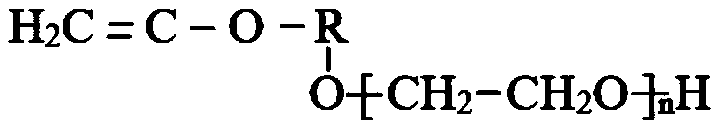

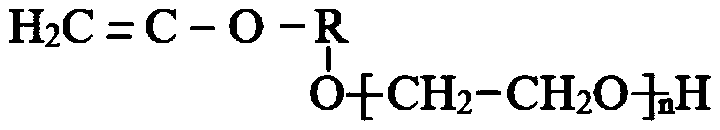

Method used

Image

Examples

Embodiment 1

[0033] In aqueous solution, use ethylene glycol monovinyl polyglycol ether, acrylic acid, hydroxyethyl acrylate, dimethylaminoethyl methacrylate, chain transfer agent, oxidizing agent and reducing agent to synthesize long effective dispersant; in aqueous solution, use sodium propenyl sulfonate, hydroxyethyl acrylate, chain transfer agent, oxidizing agent and reducing agent to synthesize thickener at 35°C±5°C; then add 10 parts of long-acting dispersant, 20 After mixing 1 part of water, 0.5 part of thickener and 0.6 part of ether defoamer, stir well at 50°C±5°C, add 0.4 part of sodium sulfate and stir well, add 4 parts of fumed silica and use high-speed stirring to stir well After that, you get it.

Embodiment 2

[0035]In aqueous solution, use n-butylene glycol monovinyl polyglycol ether, acrylic acid, methacrylic acid, hydroxypropyl acrylate, methacryloyloxyethyltrimethylammonium chloride, chain transfer agent, oxidizing agent and reducing long-acting dispersant at 40°C±5°C; in aqueous solution, use sodium propenyl sulfonate, hydroxyethyl acrylate, chain transfer agent, oxidizing agent and reducing agent to synthesize thickener at 35°C±5°C; Then mix 20 parts of long-lasting dispersant, 60 parts of water, 2.5 parts of thickener, 0.5 parts of silicone defoamer, and 0.7 part of ether defoamer, stir well at 50°C±5°C, add 0.4 Sodium sulfate and 0.8 parts of potassium carbonate are stirred evenly, and 2 parts of fumed silicon dioxide, 2 parts of silica fume, and 4 parts of nano-montmorillonite are added, and then stirred evenly with high-speed stirring to obtain the product.

Embodiment 3

[0037] In aqueous solution, use propylene glycol monovinyl polyethylene glycol ether, maleic anhydride, hydroxybutyl acrylate, 2-acrylamide-2-methylpropanesulfonic acid, chain transfer agent, oxidizing agent and reducing agent at 40 ° C ± 5 Synthesize long-acting dispersant at ℃; in aqueous solution, use sodium propenyl sulfonate, hydroxyethyl acrylate, chain transfer agent, oxidizing agent and reducing agent to synthesize thickener at 35°C±5°C; then 15 parts of long-acting After mixing dispersant, 40 parts of water, 1.5 parts of thickener, 0.4 parts of silicone defoamer and 0.5 part of ether defoamer, stir well at 50℃±5℃, add 0.4 parts of potassium sulfate and 0.4 parts of carbonic acid Stir the sodium evenly, add 2 parts of fumed silica, 2 parts of silica fume, and 2 parts of nano-montmorillonite, and then use high-speed stirring to stir evenly to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com