Automatic weighing system and method for garbage classification

An automatic weighing and garbage classification technology, applied in the directions of trash cans, garbage collection, weighing, etc., can solve the problems of poor timeliness and efficiency of removal and transportation, and achieve the effect of improving the level of informatization and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

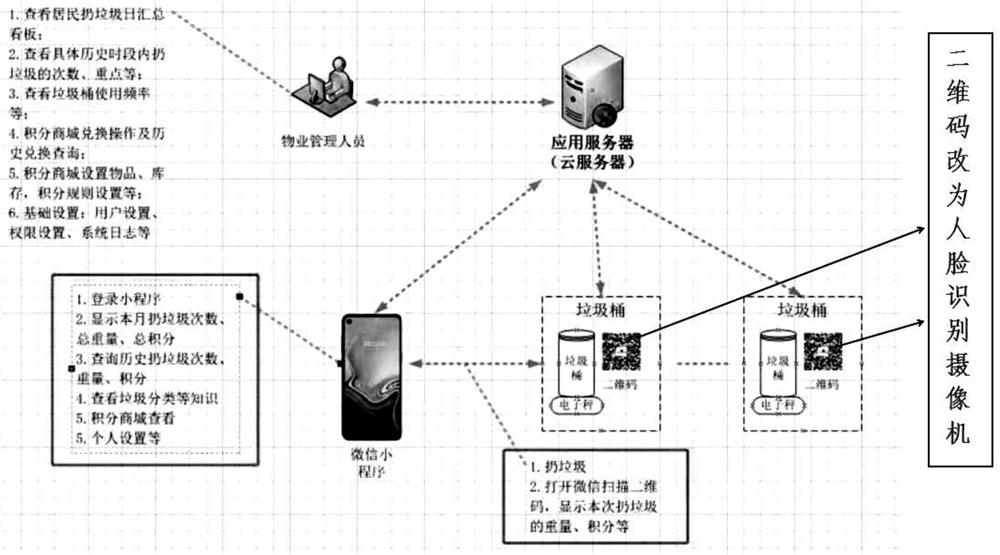

[0031] refer to figure 1 As shown, this embodiment discloses an automatic weighing system for garbage classification. The system is equipped with a face recognition all-in-one. The bluetooth electronic scale is set to transmit the delivery data back to the cloud database server in real time through the data gateway, and the mobile app automatically updates each garbage delivery data, and the cloud database server and the mobile phone app are connected to the smart community platform to realize data visualization analysis and statistics.

[0032] In this embodiment, a camera is set up at the garbage station, and the behavior of the thrower is monitored in real time through the camera, and the safety of the community is assisted in monitoring.

[0033] The kitchen waste trash can in this embodiment is used for storing and collecting garbage, and is also used for transferring garbage.

[0034] In this embodiment, the mobile phone App uploads face data information through a small...

Embodiment 2

[0040] This embodiment discloses an automatic weighing system for garbage classification, including video monitoring: monitor the behavior of the putter in real time through the camera, and assist in monitoring the safety of the community;

[0041] Face: All-in-one face recognition machine, face entry or entry on the App when the first launch;

[0042] Automatic weighing: a bluetooth electronic scale is embedded under the kitchen waste bin to realize automatic weighing each time garbage is placed, and the delivery data is sent back to the cloud database server in real time through the gateway;

[0043] Keep the current trash can: Use the current kitchen trash can to load and transport garbage to reduce construction costs;

[0044] Mobile phone applet synchronization data: Every time you throw garbage data, it will be automatically updated and displayed in your hand, and can be used for reward points;

[0045] Data gateway: through the deployment of the gateway, the weighing d...

Embodiment 3

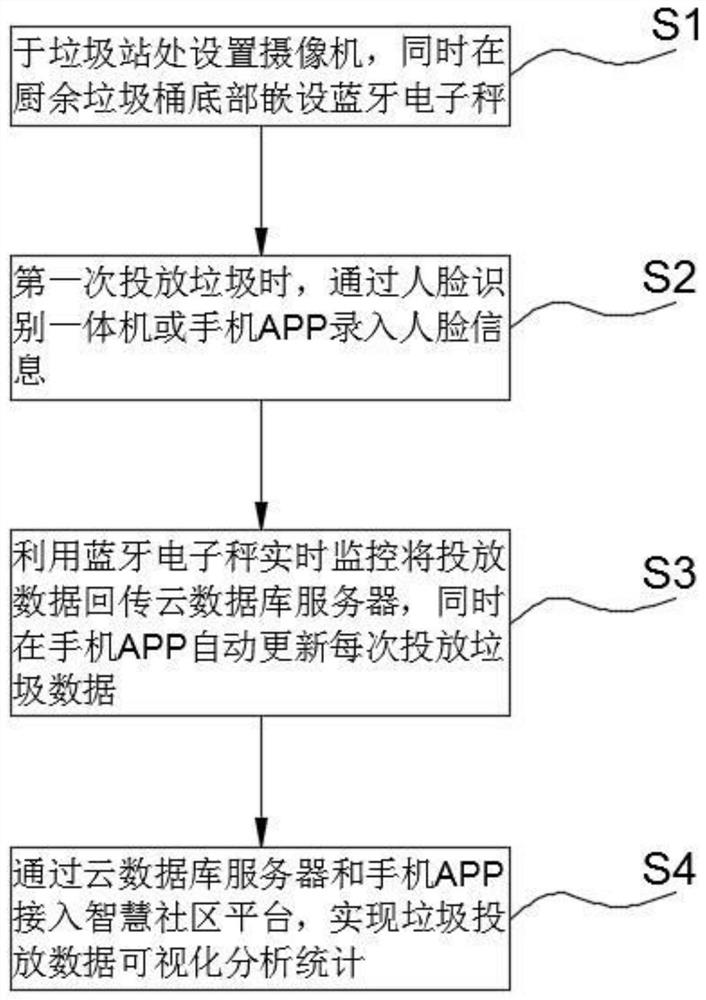

[0051] This embodiment discloses a garbage sorting automatic weighing method, including the following steps:

[0052] S1 sets up a camera at the garbage station, and embeds a bluetooth electronic scale at the bottom of the kitchen waste bin;

[0053] When S2 puts out garbage for the first time, enter the face information through the face recognition all-in-one machine or mobile app;

[0054]S3 uses the bluetooth electronic scale to monitor in real time and send the delivery data back to the cloud database server, and at the same time, the mobile app automatically updates the garbage delivery data every time;

[0055] S4 connects to the smart community platform through the cloud database server and mobile app to realize the visual analysis and statistics of waste disposal data.

[0056] In summary, under the condition of using the existing trash can, the present invention adds some data collection, information communication, video processing and other equipment to realize inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com