Automatic glue preparation device

A technology of automatic glue dispensing and movable rod, which is applied in the direction of mixer accessories, transportation and packaging, dissolution, etc., can solve the problems of inconvenience, a large number of air bubbles, laborious operation, etc., and achieve the goal of ensuring uniformity, convenient weighing, and increasing the amount of preparation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

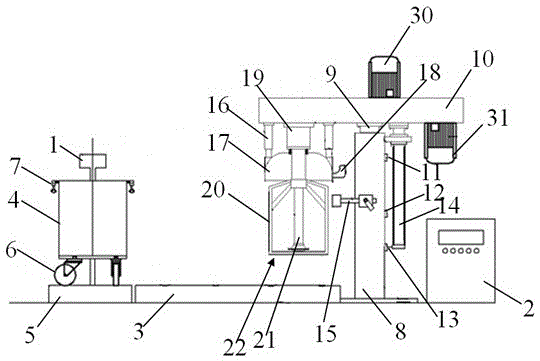

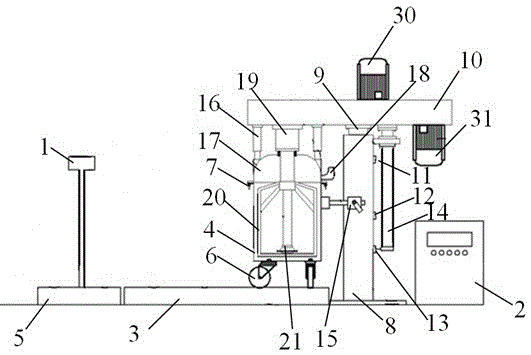

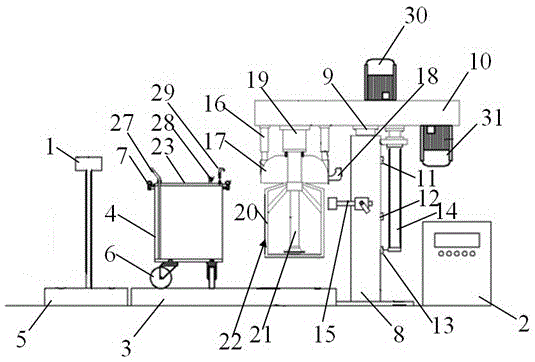

[0036] An automatic glue dispensing device of the present invention will be described in detail below in conjunction with the drawings and embodiments of the description:

[0037] Such as Figure 1~3 As shown, an automatic glue dispensing device includes a weighing system, a stirring system, a sub-packaging system and a mixing tank 4,

[0038] The weighing system comprises an electronic balance 1 and a display 2 connected by a signal line;

[0039] The mixing system includes a working platform 3 and a support column 8, the right side wall of the support column 8 is equipped with an upper limiter 11, a middle limiter 12 and a lower limiter 13 from top to bottom, and the middle part of the left side wall of the support column 8 is equipped with a Barrel fixed mount 15, cylinder 9 is installed above the support column 8, mobile platform 10 is installed above the cylinder 9, fixed rod 14 upper ends are fixed with the lower surface of mobile platform 10, and fixed rod 14 is positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com