Method for enhanced nitrogen removal by utilizing constructed wetland blockages

A technology for artificial wetlands and blockages, applied in chemical instruments and methods, water pollutants, anaerobic digestion treatment, etc., to achieve the effects of shortening the preparation time, improving the removal effect, and improving the denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

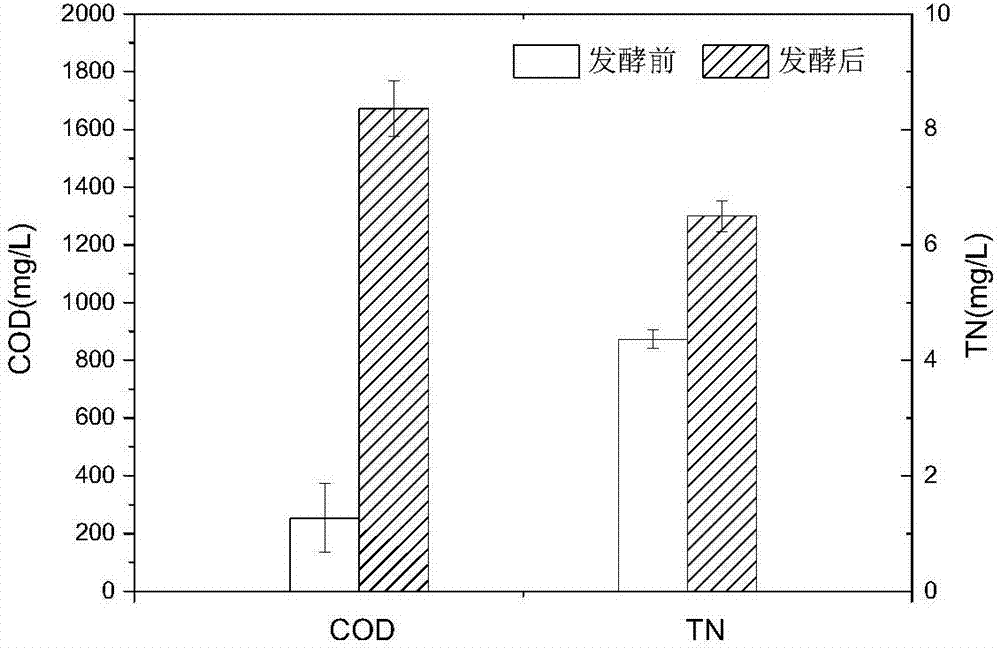

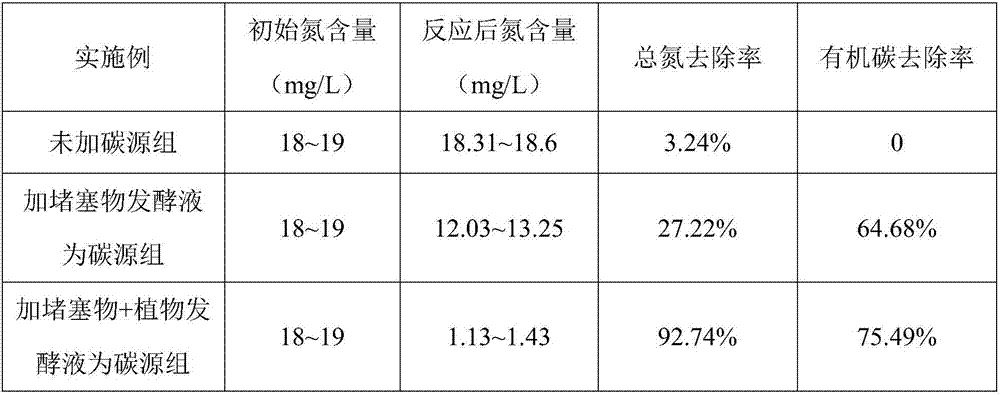

[0034] Carbon source preparation of separate blockages: Excavate the blockages from the constructed wetland system to measure the water content of 63%, remove large particles of impurities, weigh 165g into a 2L Erlenmeyer flask, add 1.5L of water, and use 10M sodium hydroxide Adjust the pH to 12, seal the mouth of the bottle with plastic wrap, and ferment continuously in a shaker at 28°C and 120rpm / min for three days. The release of organic carbon source and total nitrogen is shown in figure 1 , the results show that COD can be obtained from the third day onwards Cr High-carbon and low-nitrogen carbon sources with a content of 1600mg / L and a TN content of less than 6mg / L.

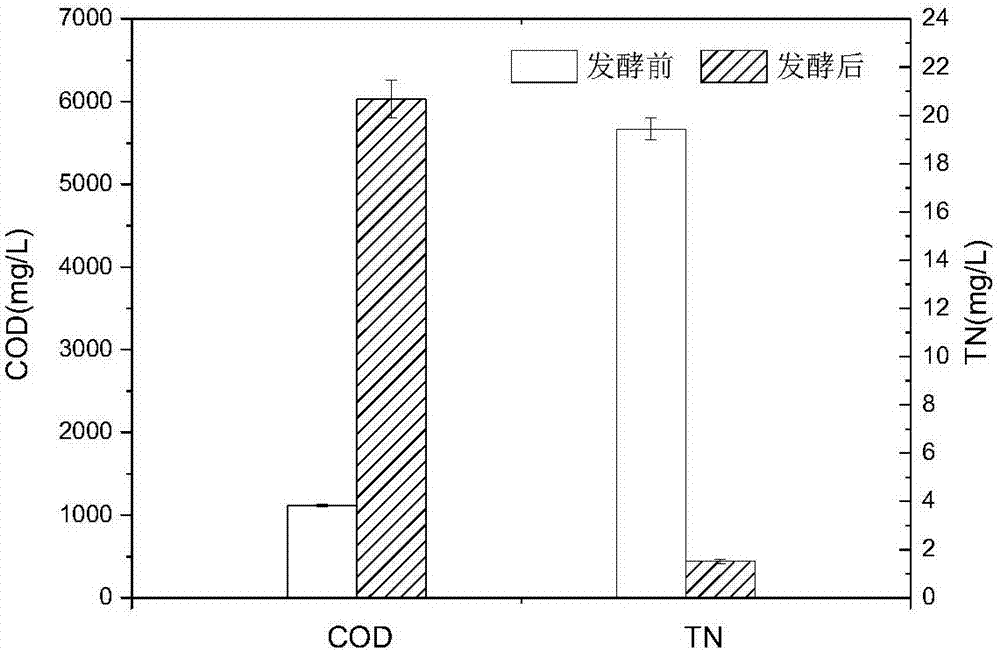

[0035] Carbon source preparation of blockage + plant: Harvest pikegrass from the constructed wetland system, cut it to a small section of about 2cm with scissors, dry the water, add 37.5g of pikegrass according to the proportion, after 165g of blockage, add 1.5L of Water, adjust the pH to 12 with 10M sodiu...

Embodiment 2

[0041] Take blockages from the constructed wetland system, remove large particles of impurities, weigh 110g into a 2L conical flask, add 25g of dried pike grass plants, add 1L of water according to the solid-to-liquid ratio, and adjust the pH with 10M sodium hydroxide to 12. Take plastic wrap to seal the bottle mouth, and ferment continuously for 3 days in a shaker at 28°C and 120rpm / min. The supernatant of the fermentation broth was taken to determine the COD Cr The content is 3572mg / L, collected as carbon source, according to COD Cr Add the ratio of / N to 6 into the water of the artificial wetland small test system, and measure the denitrification effect after the system has been running for one day. The removal rate of total nitrogen can be increased from 53% to 98% in the control group without adding plugging fermentation broth. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com