Mud content detection device for concrete aggregate

A technology of concrete aggregate and detection device, which is applied in the direction of removing certain components and weighing, etc., can solve the problems of low degree of automation, reduce the efficiency of aggregate detection, and increase the labor intensity of workers, so as to reduce labor intensity and detect The process is convenient and rapid, and the effect of reuse is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

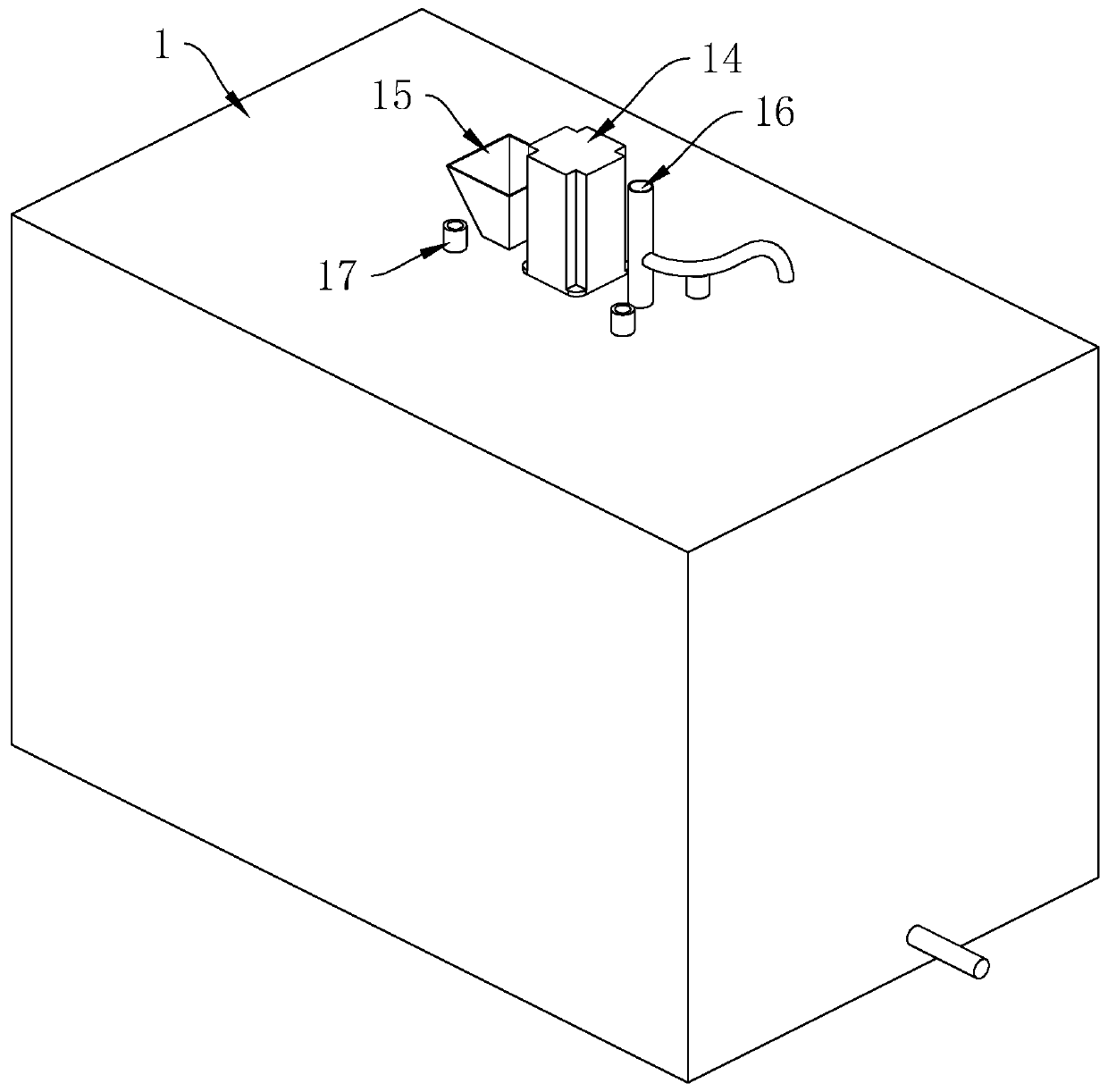

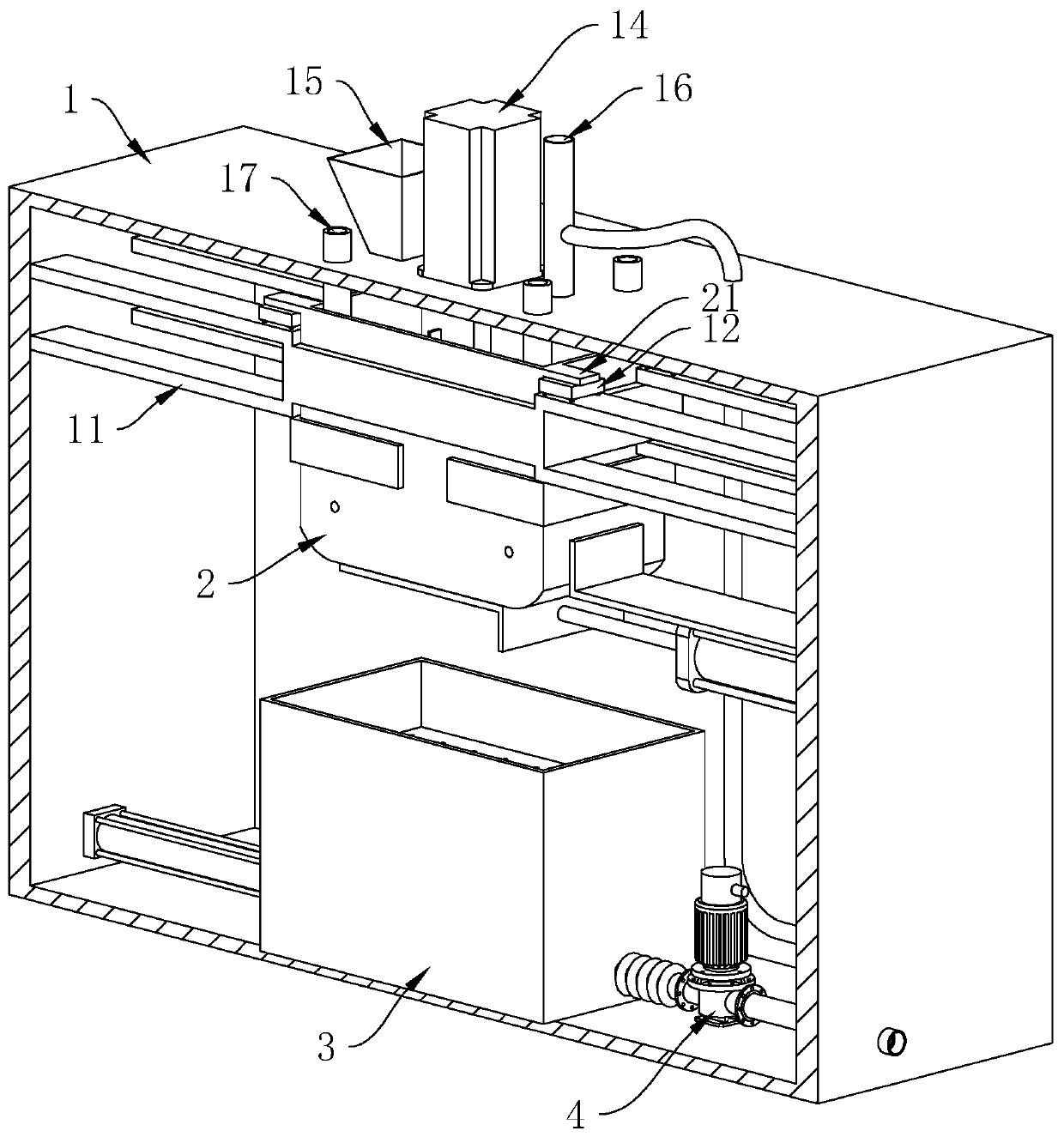

[0037] Such as figure 1 , figure 2 As shown, a concrete aggregate mud content detection device includes a detection box 1, and a detection cylinder 2 with an upper end opening is suspended in the detection box 1. The inner wall of the upper end of the detection box 1 is provided with a support frame 11 , the outer wall of the upper end of the detection cylinder 2 is provided with a corner ear 21 above the support frame 11 , and a weighing instrument 12 is arranged between the support frame 11 and the corner ear 21 .

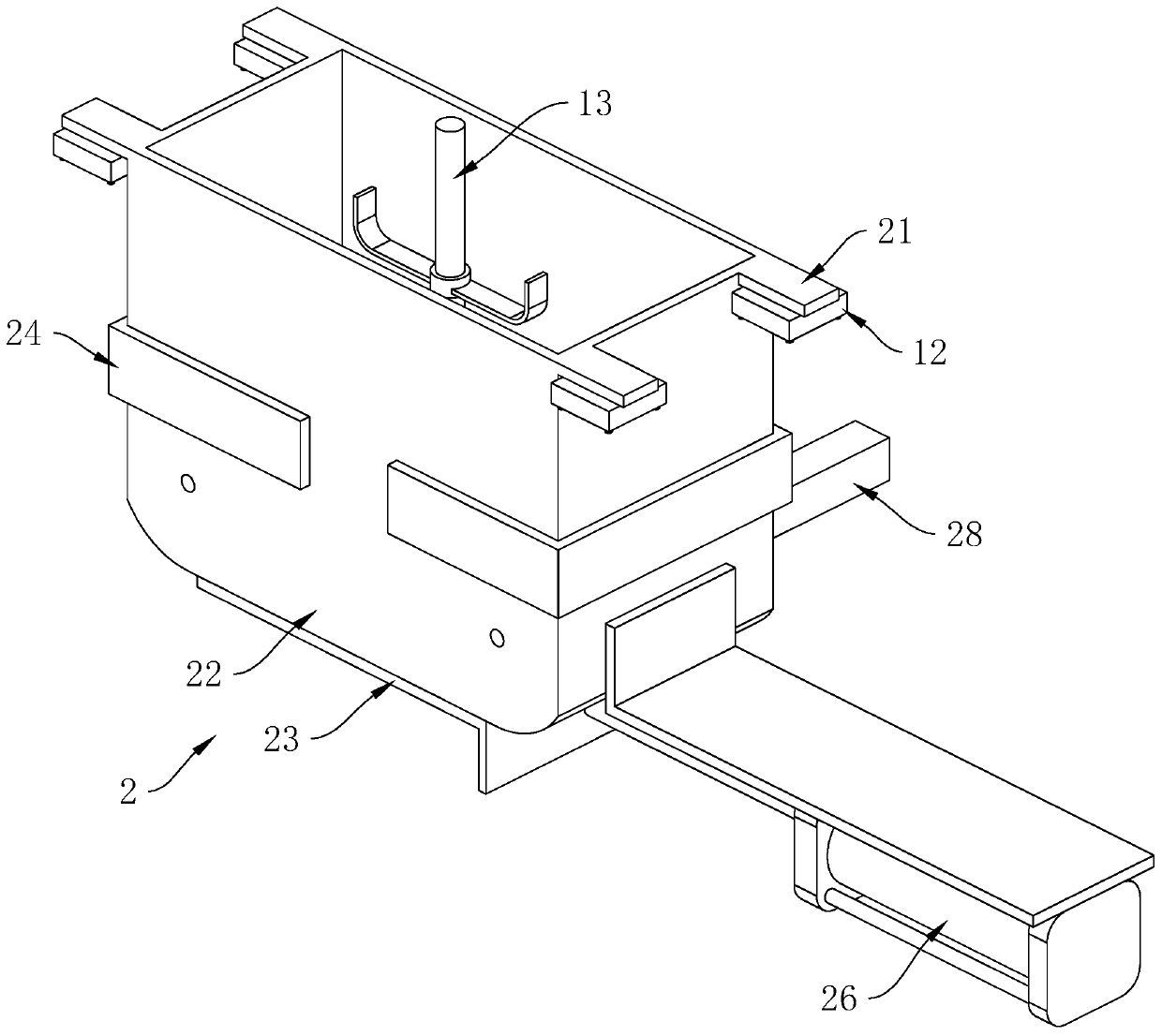

[0038] Such as figure 2 , image 3 As shown, the detection cylinder 2 includes a cylinder body 22 and a switch plate 23 covering the bottom of the cylinder body 22. A plurality of electric heating plates 24 are arranged on the outer wall of the lower end of the cylinder body 22, and a number of leakage holes 25 are evenly distributed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com