Semi-automatic hot-press molding production line for brake pads for brakes for passenger cars

A hot-press forming and brake technology, which is applied in the field of semi-automatic production lines for hot-press forming of brake pads for passenger cars, to achieve the effects of ensuring consistency, improving production efficiency and product quality, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

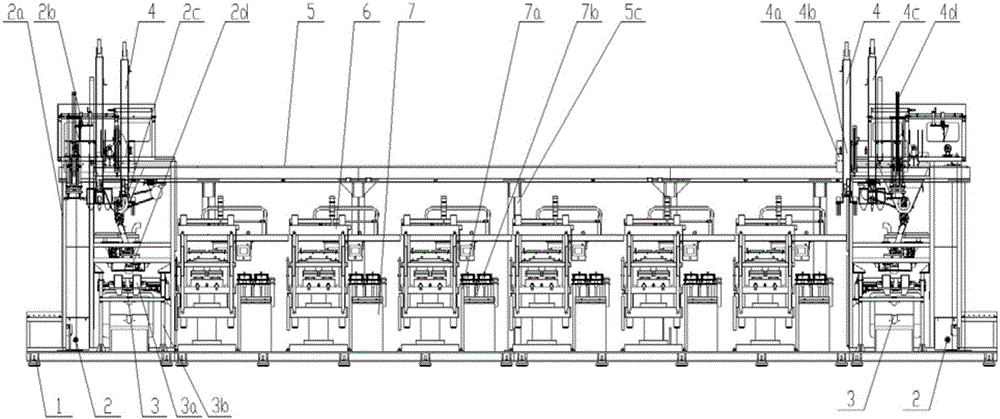

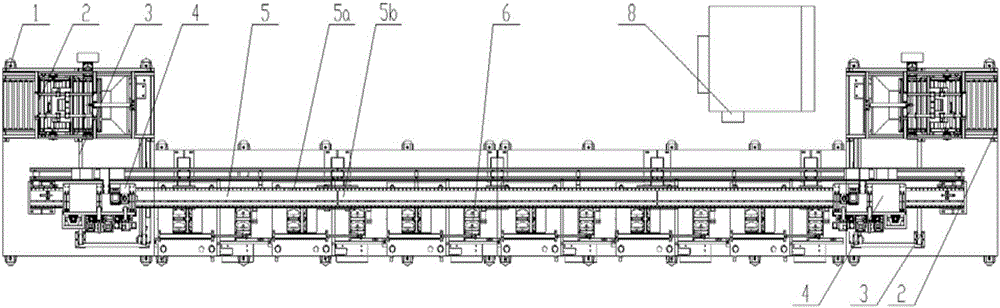

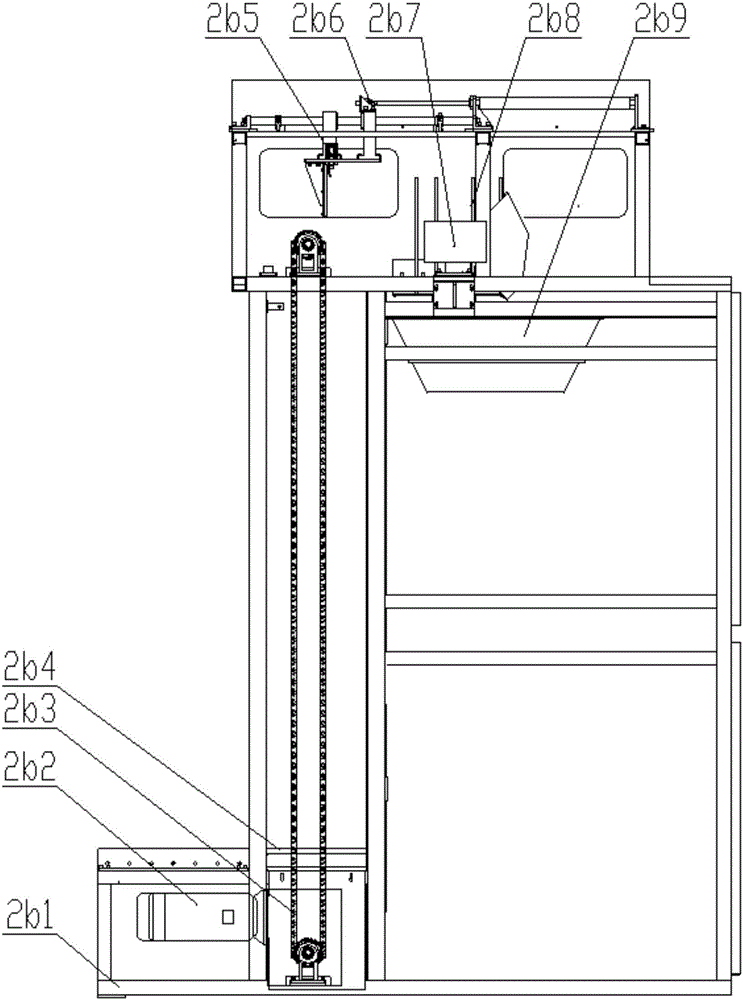

[0018] The present invention will be described in further detail below. see figure 1 and figure 2 , a semi-automatic production line for hot press forming of passenger car brake pads, characterized in that it consists of an installation base 1, two sets of feeding mixing and weighing systems 2, two sets of transfer mechanisms 3, two sets of service robot trolleys 4, trolleys Composed of walking truss 5, six hot press forming machines 6, six sets of steel back lifting mechanisms 7, and oil source 8. The semi-automatic production line for hot press forming of passenger car brake pads has a linear layout. The bottom surface of the installation base 1 is equipped with shock-absorbing feet, which can be placed directly on the level ground. The top plate of the installation base 1 is the installation bottom plate for the rest of the components; The material stirring and weighing system 2 is composed of a supporting frame 2a, a fully automatic feeding mechanism 2b, a stirring and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com