Weighing method applicable to truck scale

A truck scale and weighing technology, which is applied in the direction of weighing, special scales, measuring devices, etc., can solve the problems of large difference and poor compensation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Figure 4 Shown is the main structure of the weighing part of the truck scale applicable to the present invention: the output end of each load cell is connected to a data acquisition device, and the data acquisition device includes a conditioning circuit 1 and an analog-to-digital conversion circuit 2; the weighing signal is in the conditioning circuit 1 is amplified and filtered, and converted into a digital signal by the analog-to-digital conversion circuit 2, and the digital signal is transmitted to the microprocessor 3; the microprocessor is also equipped with a power module 4, a keyboard 6, a display 7 and a communication interface 8; The power supply module 4 supplies power for the conditioning circuit 1, the analog-to-digital conversion circuit 2, the microprocessor 3, and the like. During training, the microprocessor 3 is connected to the external computer 5 through the communication interface 8; during online weighing, the external computer 5 is evacuated.

Embodiment 2

[0088] Embodiment 2: method and steps of actual weighing model training.

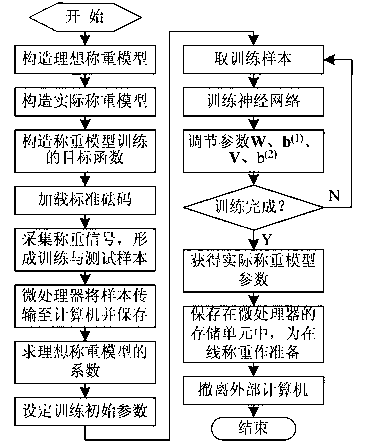

[0089] In this embodiment, the truck scale has 8 load cells ( N =8), the measuring range is 40 tons, the maximum capacity of each load cell is 20 tons, the division number is 4000, and the verification division value e and the actual division value d Both are 10kg; the microprocessor 3 adopts the high-performance single-chip microcomputer MSP430F449 of TI Company. see figure 1 , the steps to train the actual weighing model are as follows:

[0090] (1) Construct an ideal weighing model as the constraint condition of the truck scale weighing system: take N The weighing signal output by the load cell is the input and A(X) is the output, construct the ideal weighing model of the truck scale, as shown in formula (1);

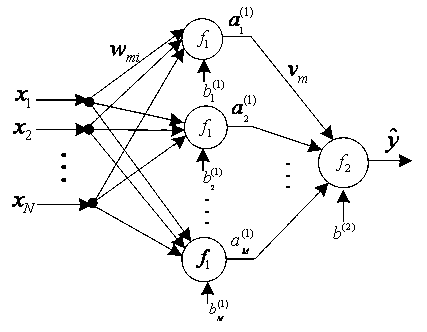

[0091] (2) Construct the actual weighing model of the truck scale based on the neural network: take the weighing signal of 8 sensors as the input and the weighing result of the truck s...

Embodiment 3

[0101] Embodiment 3: online weighing.

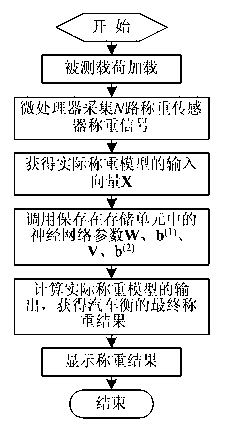

[0102] In this embodiment, the truck scale has 8 load cells ( N =8), the measuring range is 40 tons, the maximum capacity of each load cell is 20 tons, the division number is 4000, and the verification division value e and the actual division value d Both are 10kg; the microprocessor 3 adopts the high-performance single-chip microcomputer MSP430F449 of TI Company, and utilizes the actual weighing model that has been trained and qualified in the embodiment 2 to carry out online weighing. see figure 2 , the online weighing steps are as follows:

[0103] (1) Loading of the measured load: that is, the truck is loaded on any position of the truck scale body, and the weighing signal is collected after stabilization;

[0104] (2) Microprocessor acquisition N The weighing signal of the load cell: the system collects the output signal of the load cell of 8 channels through the load cell, the conditioning circuit 1, the analog-to-digital con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com