Washing and liquid coating machine for test tube

A liquid coating and washing technology, which is applied to the device, coating, liquid spraying device, etc. for coating liquid on the surface, which can solve the problems of non-compliance with the requirements of GMP standards, inability to form large-scale production, and inability to recycle and use. High pass rate, fast working speed, good recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

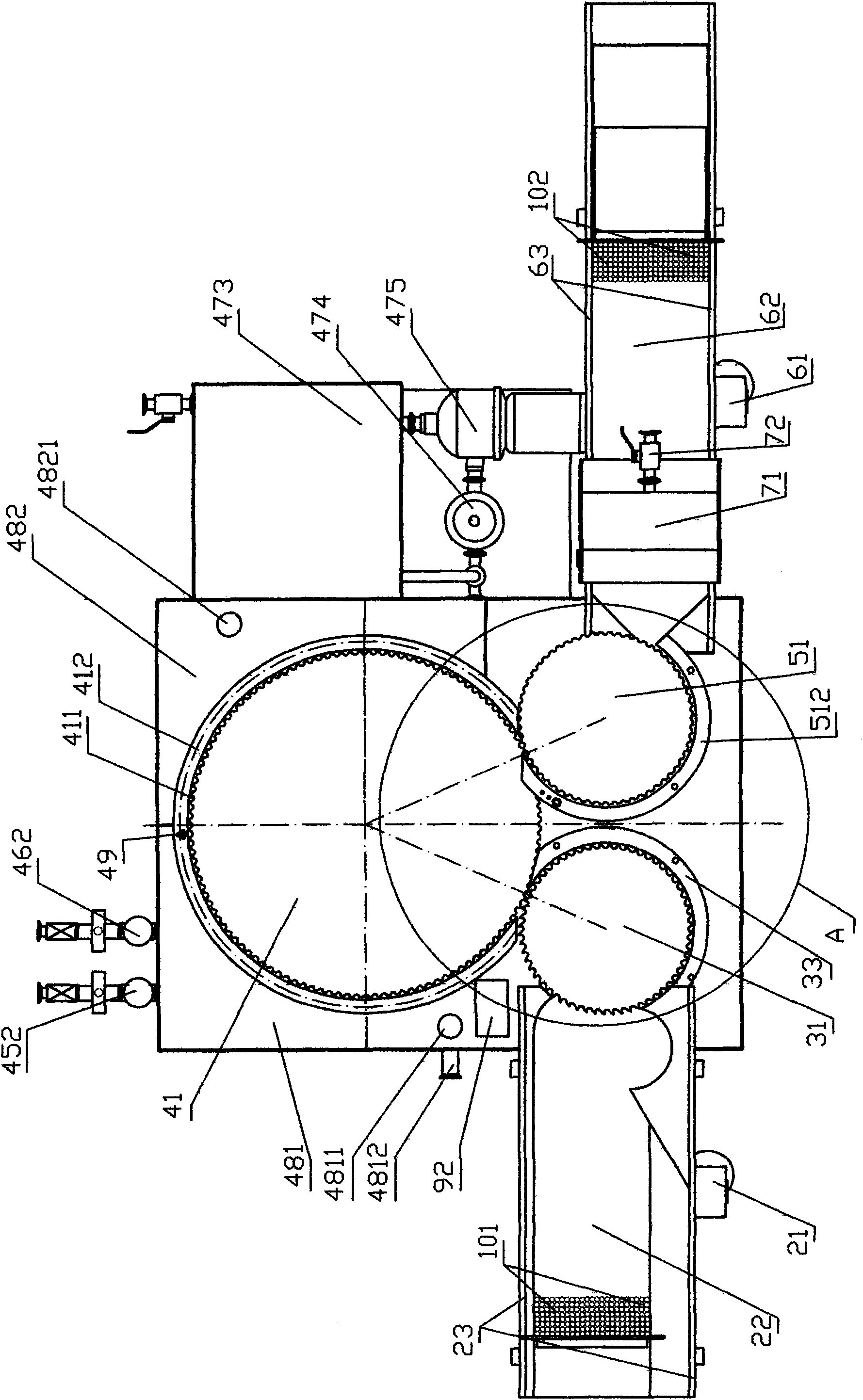

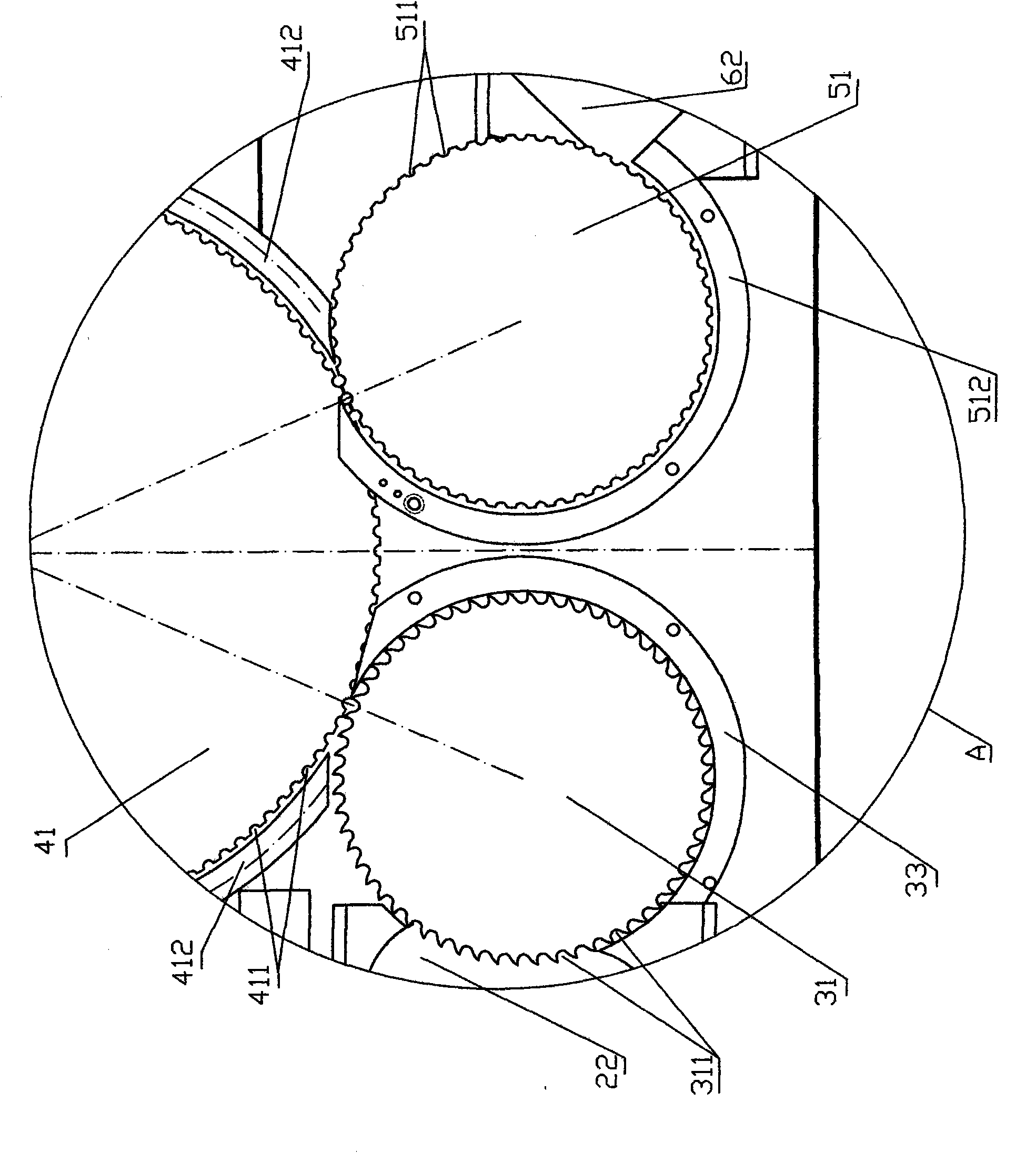

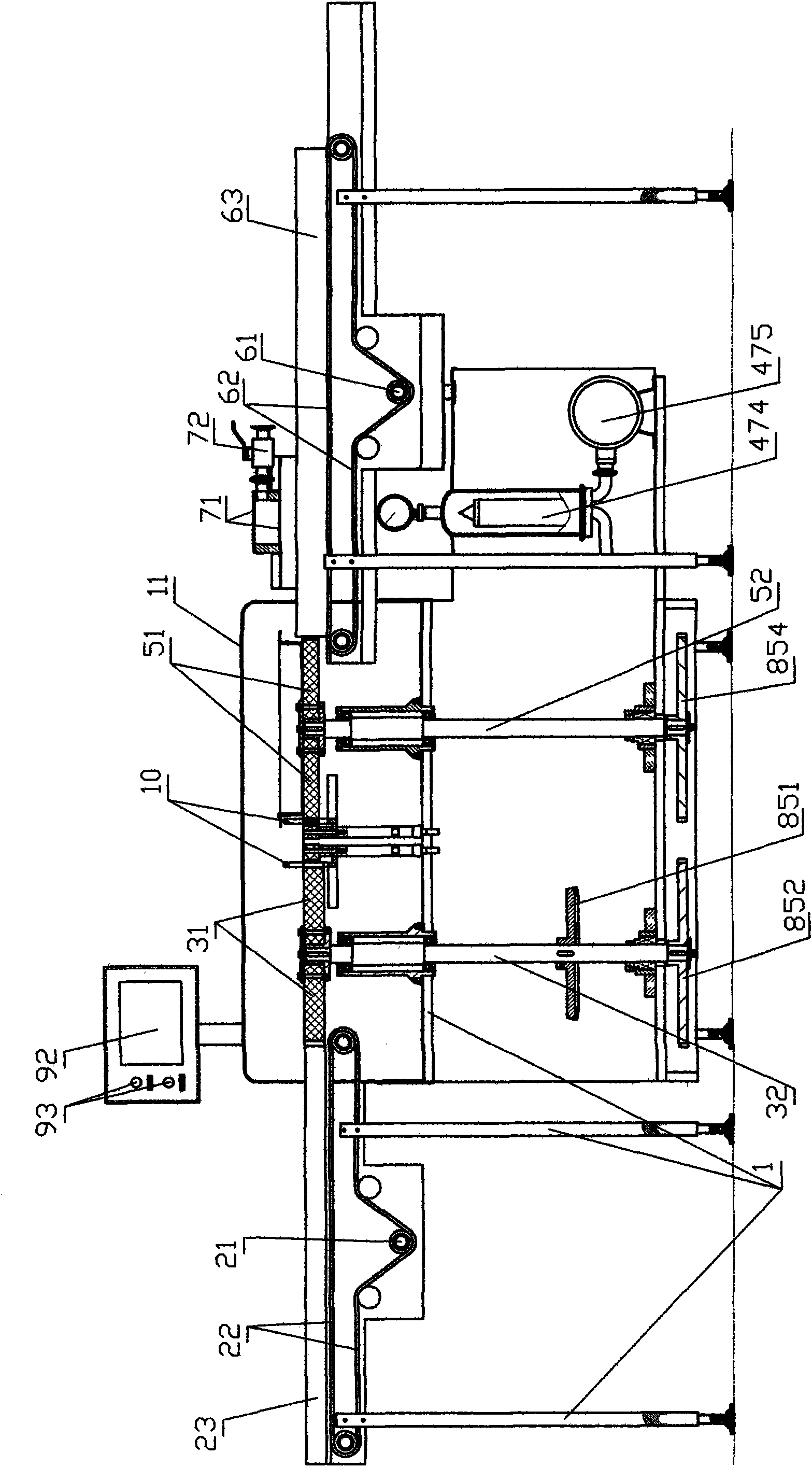

[0021] Such as Figure 1-4 Shown: a test tube washing and liquid coating machine, which includes a frame 1, a tube feeding mechanism, a tube feeding mechanism, a washing and coating liquid mechanism, a tube outlet mechanism, a tube feeding mechanism, a shower tube mechanism, a power transmission mechanism and an operation control system, The pipe transport mechanism includes a pipe motor 21 and a pipe conveyor belt 22. The pipe conveyor belt 22 is a soft belt, preferably a mesh belt. The pipe conveyor belt 22 is movably mounted on the frame 1 through shafts and bearings. The pipe motor 21 is driven by The structure is connected to the installation shaft of the pipeline conveyor 22 (there can be multiple transmission modes, such as transmission shafts, gears, etc., or it can be directly connected to the installation shaft of the pipeline conveyor 22, as long as it is an existing conventional transmission mode. The concept created by the present invention) realizes the transmissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com