Roller washing machine

A drum washing machine and cylinder technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of cost reduction and maintenance, many wearing parts, complex structure, etc., and achieve reduction and maintenance, wearing parts The effect of less and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

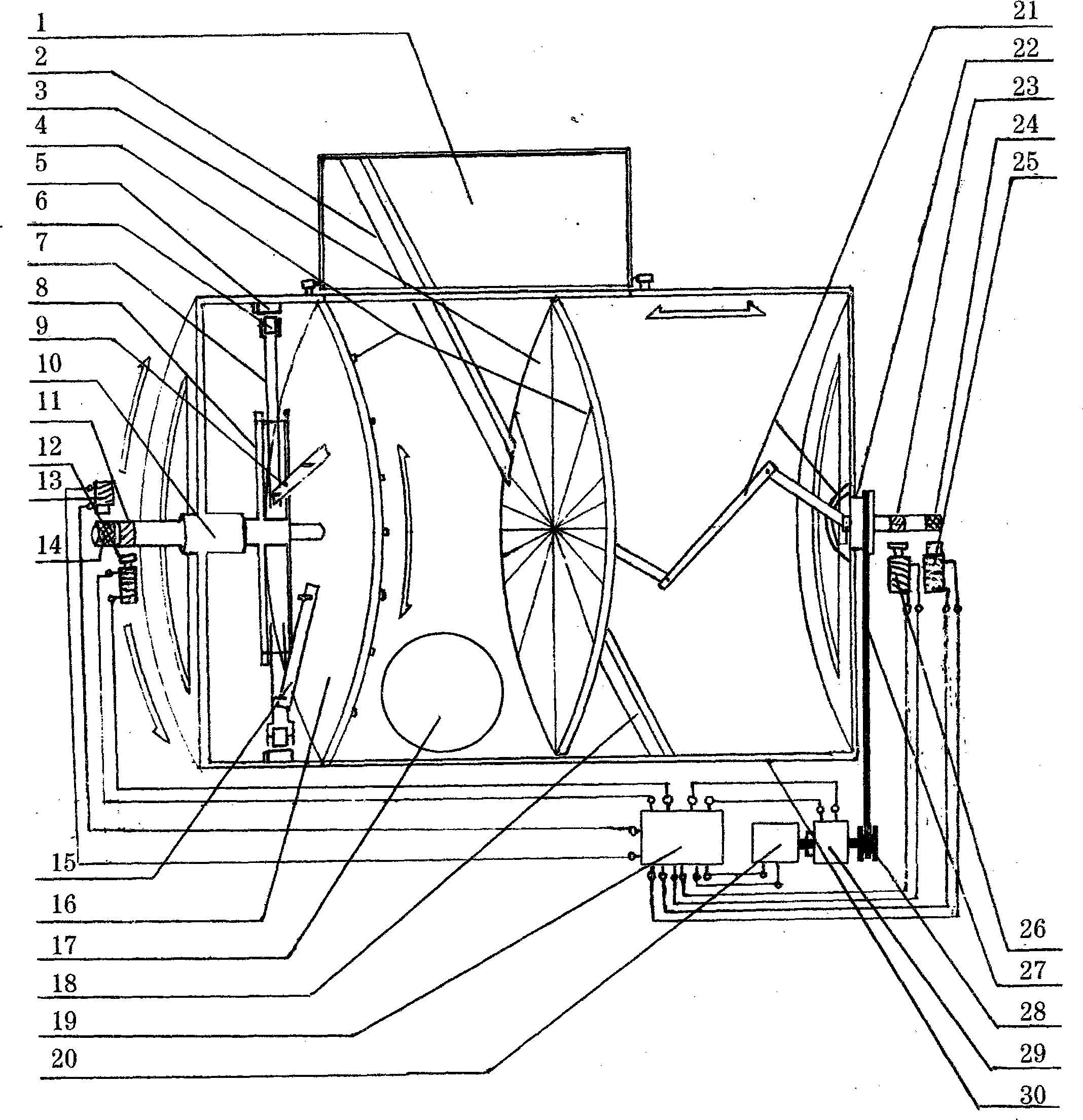

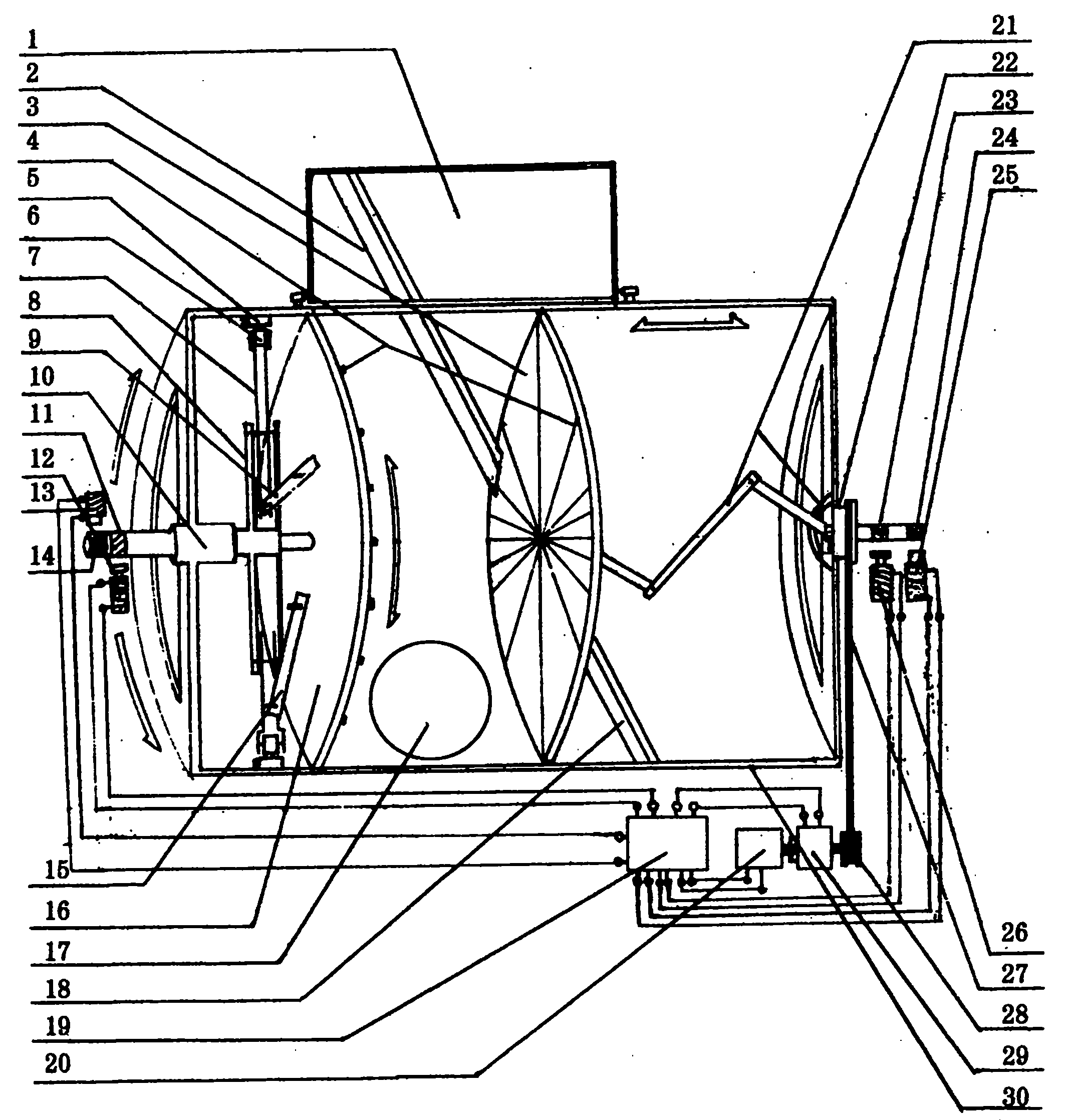

[0012] The cylinder 30 is provided with a spiral slideway 18, the spiral slideway 18 is equipped with a movable kneading disc 3, the opposite is a rubbing disc 16 that can alternately rotate clockwise and counterclockwise, and the cylinder 30 can rotate.: electronically controlled mechanical brake ( 1) 12 is for forward rotation braking or forward and reverse rotation braking, electronically controlled mechanical brake (2) 26 is for forward rotation braking or forward and reverse rotation braking, and electronically controlled transmission 29 is for single-stage or high-low two-stage speed change. Knead the disc 3 and the rubbing disc 16 are provided with convex ribs 4 radiating from the center of the circle to the circumference, a part of the spiral slideway 18 is arranged on the cylinder cover 1, and the rubbing disc holder 8 is provided with a magnet (1) 14 and a brake ring (1) on the outer part of the cylinder 11. Set the rotation detector (1) 13 and the electromechanical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com