Waste box for sheet metal parts

A technology for waste bins and sheet metal parts, applied in metal processing equipment, feeding devices, manufacturing tools, etc., can solve problems such as short service life, inconvenient use, and affecting production efficiency, so as to improve production efficiency and facilitate unloading , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

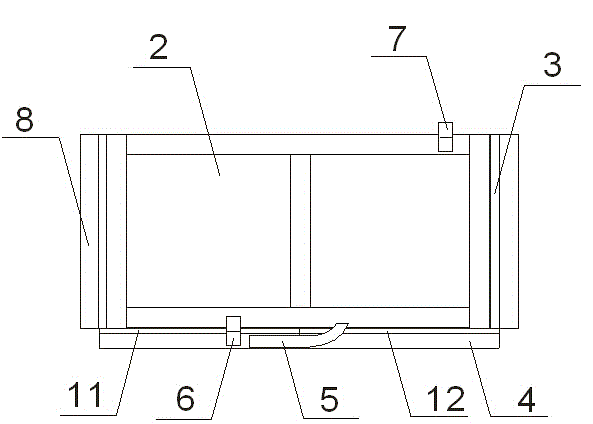

[0010] Example: see figure 1 , A sheet metal scrap box, including a rectangular box body, the box body includes a bottom plate, two side plates 2 and two end plates 3, the two end plates 3 and the two side plates 2 are fixedly connected to form a frame; The bottom plate, the side plate and the end plate are all metal plates with a thickness of 5-10 mm, which can further improve the stability of the box body and prolong its service life. The bottom plate includes a left bottom plate 11 and a right bottom plate 12, and the left bottom plate 11 and the right bottom plate 12 are respectively rotatably connected with the two end plates 3; a bottom bracket frame 4 is respectively fixed under the left bottom plate 11 and the right bottom plate 12. A guide rod 5 is respectively provided on the two bottom bracket frames 4, and the two guide rods 5 are respectively located on both sides of the frame; the guide rod 5 includes a horizontal section and an upwardly curved arc section, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com