Safe and intelligent shear-fork forward-moving type forklift

A scissors and safety technology, applied in the direction of hoisting equipment safety devices, lifting devices, etc., can solve the problems of easy shaking of goods, uneven force on the load-carrying wheels, and impact on service life, so as to improve unloading efficiency and prevent goods from dumping , Improve the effect of loading efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

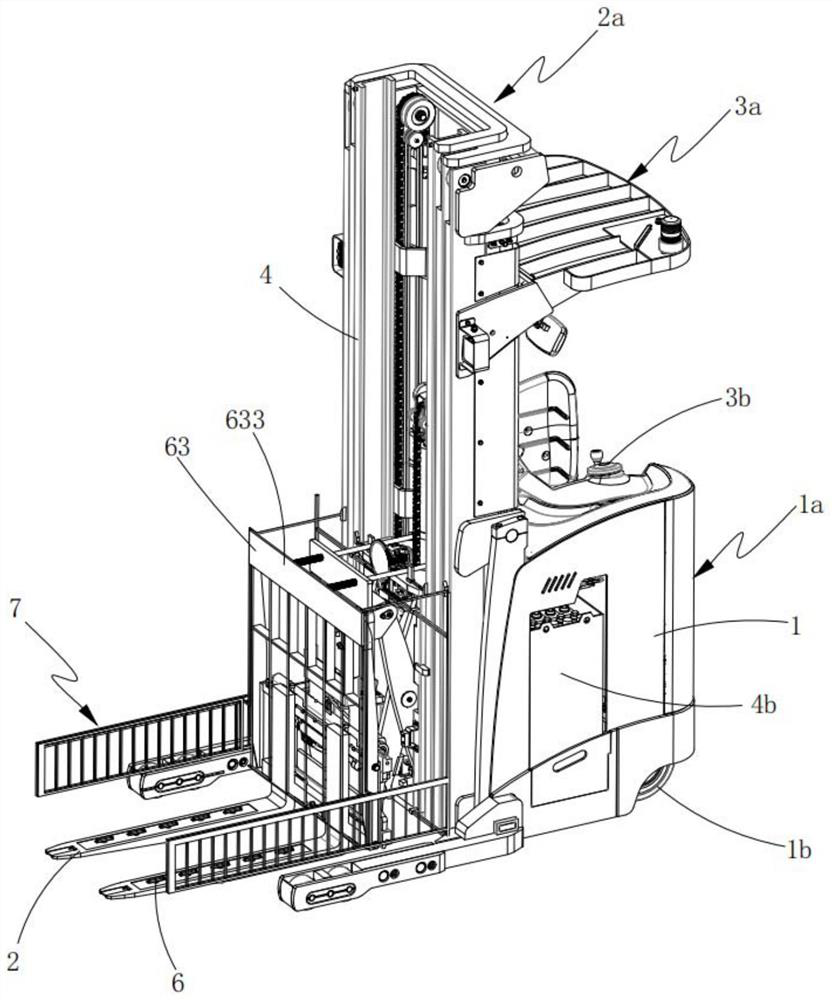

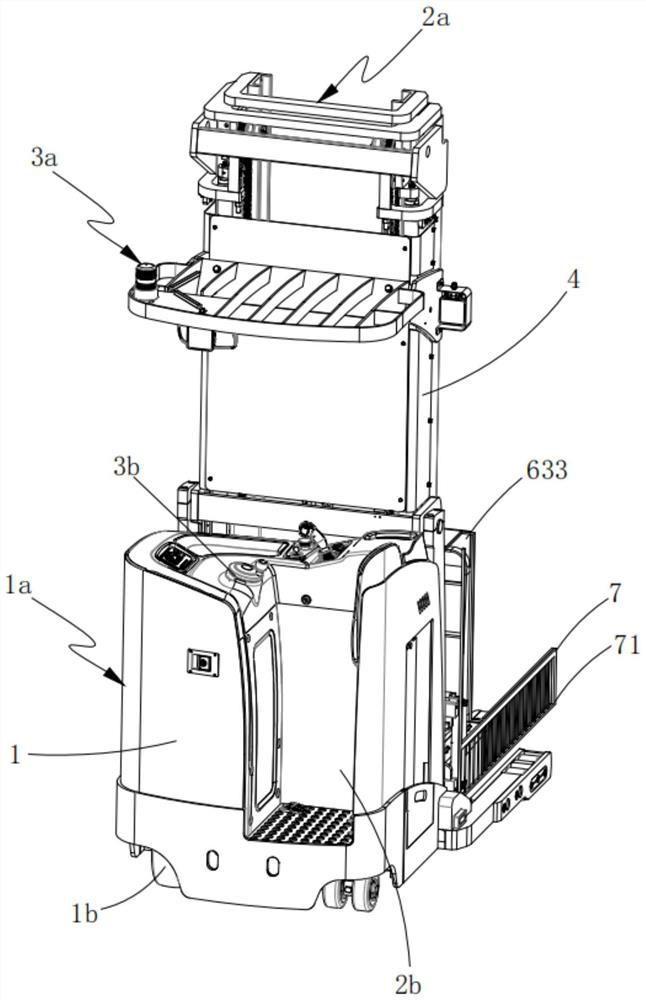

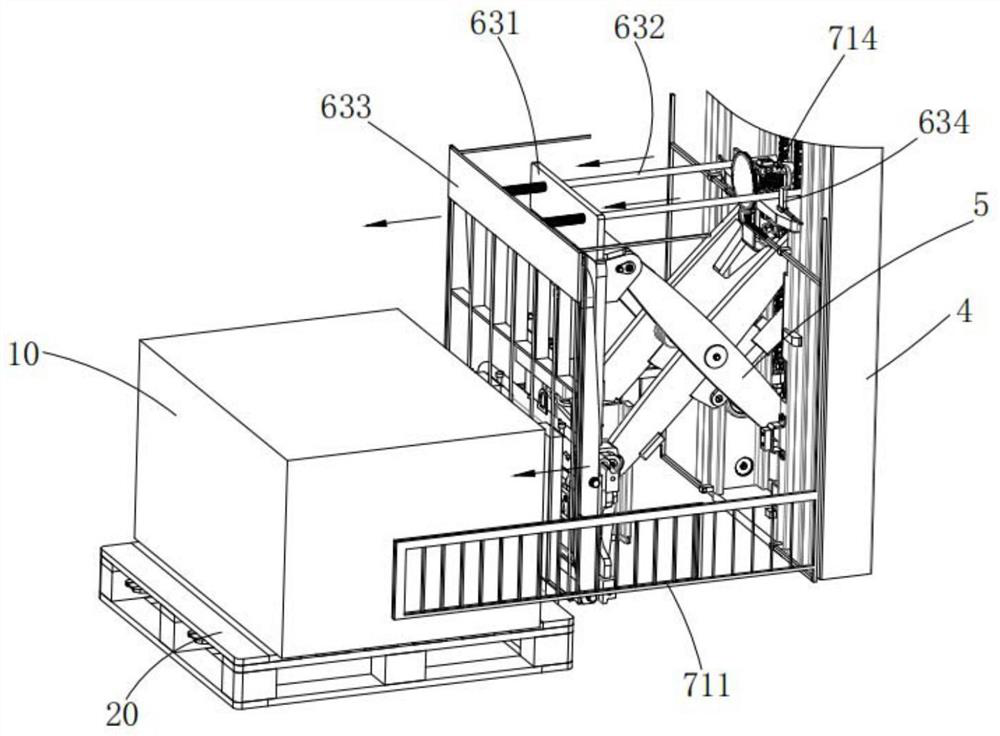

[0050] Such as figure 1 and figure 2 As shown, a safe and intelligent scissor reach forklift includes a body part 1a, a mast part 2a arranged on the front side of the body part 1a, and a roof guard part 3a arranged on the upper side of the body part 1a; Part 1a includes a vehicle frame assembly 1, a drive unit 1b is provided on the left rear side of the vehicle frame assembly 1, a station cab 2b is provided on the right rear side, and a control unit is provided above the front side of the station cab 2b. unit 3b, a battery unit 4b is arranged below the control unit 3b, and a hydraulic station 6 is arranged above the drive unit 1b; the mast part 2a includes a fork 2 and a mast structure 4, and the mast structure 4 are provided with a scissor structure 5 that can move up and down along the door frame structure 4, the fork 2 is arranged at the front end of the scissor structure 5, and also includes a support structure 6 installed on the fork 2 and a set Anti-dumping structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com