Automatic member-embedding injection mould

An insert injection molding and mold technology, applied in the direction of coating, etc., can solve the problems of limited connection accuracy, discontinuous production process, long production cycle, etc., and achieve the effect of fast blanking, high stability and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

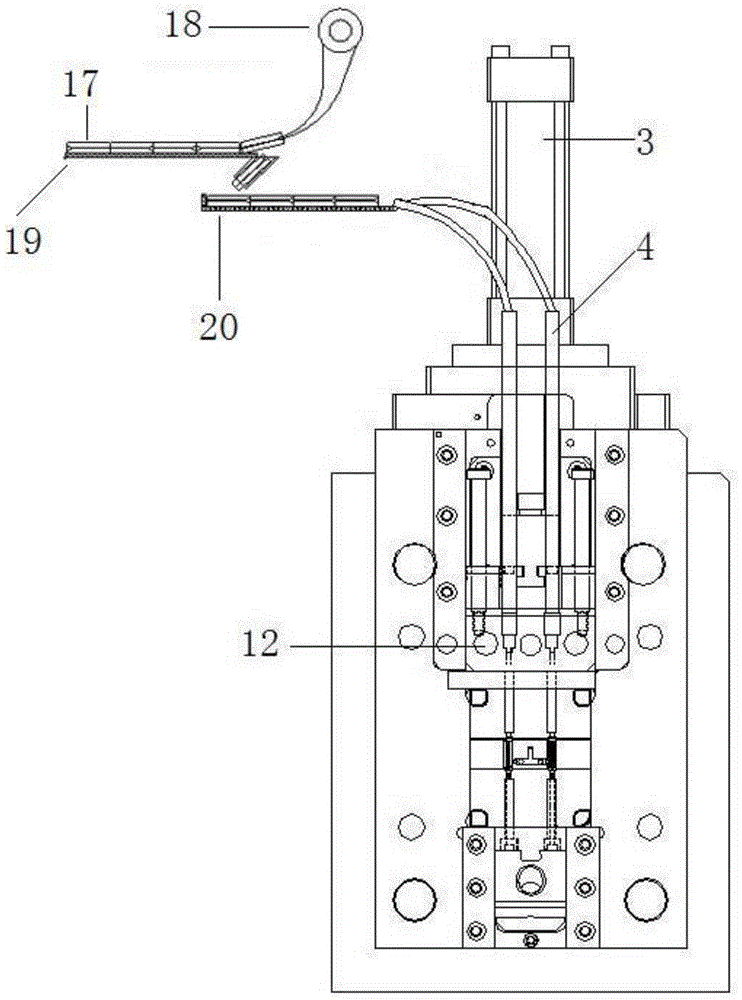

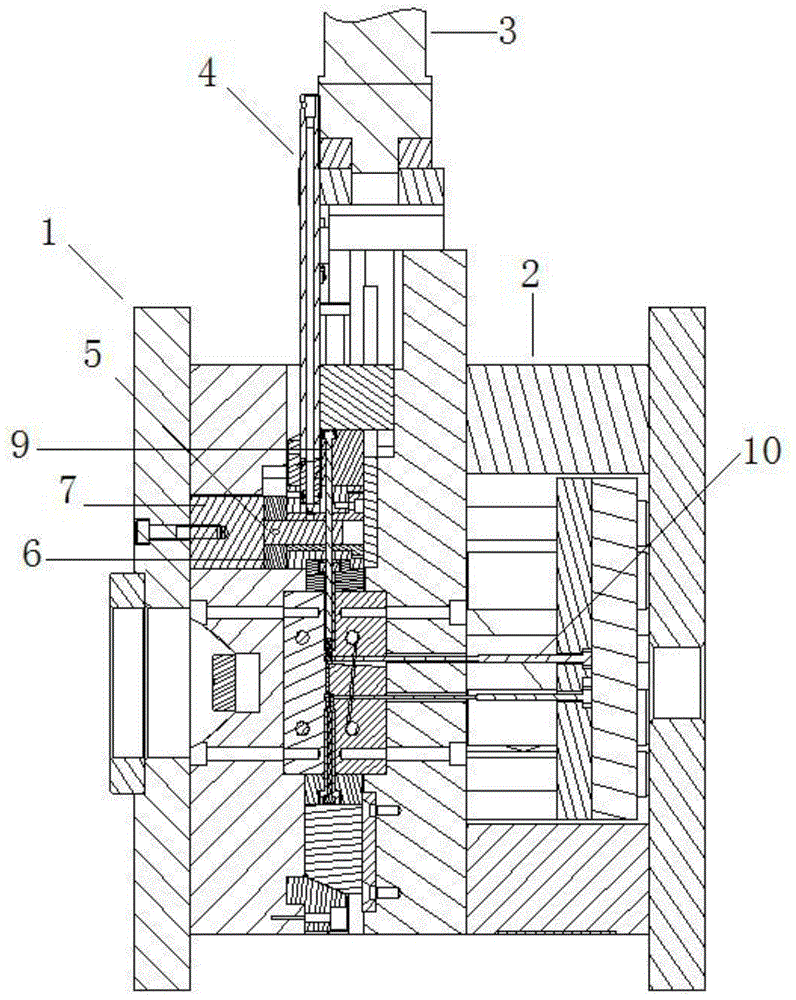

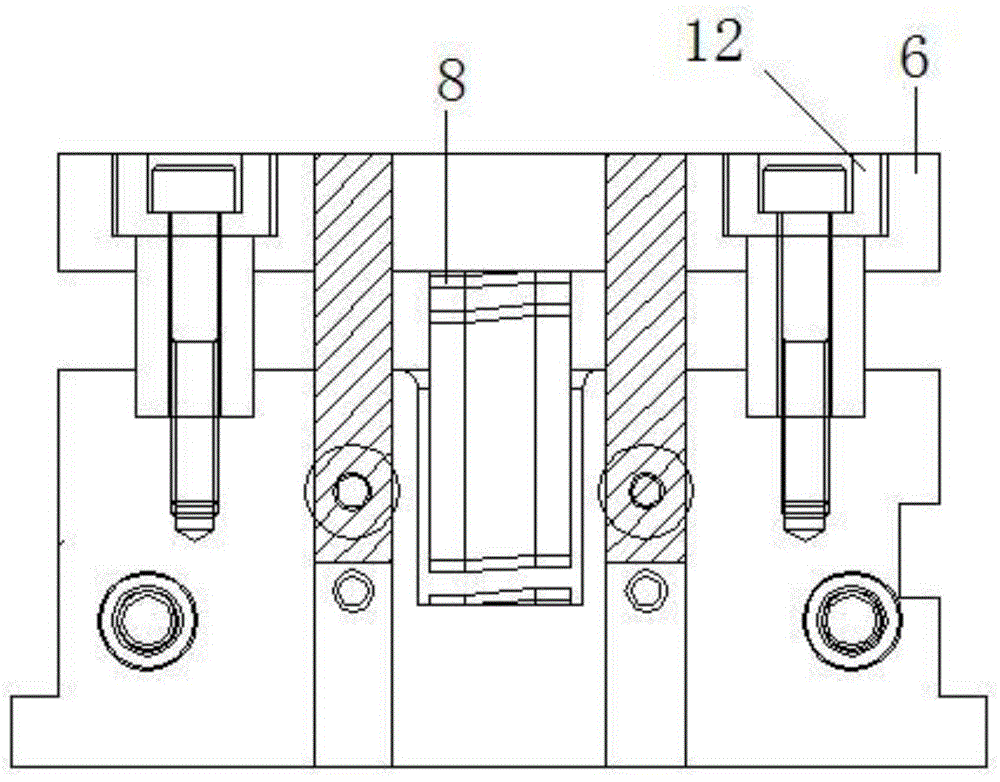

[0024] Such as figure 1 , figure 2 , image 3 , Figure 5 In the shown embodiment, an automatic insert injection mold includes an upper mold 1, a lower mold 2, a cylinder 3, and a blanking mechanism. The blanking mechanism includes a blanking tube 4 connected to a vibrating plate. The lower end of the feeding pipe 4 is provided with a feeding push block 5 with a material holding hole, and the feeding push block 5 is located in a push block groove slidingly connected with the feeding push block 5, and the described feeding push block 5 is provided with There is a push plate 6, the front of the push plate 6 is in contact with the upper mold pressing block 7 in the upper die 1, the back of the push plate 6 is provided with a spring 8, and the spring 8 is in a compressed state when the mold is closed. The blanking mechanism also includes a feeding push rod 9 driven by the cylinder 3. The lower end of the feeding push rod 9 is facing one end of the material holding hole, and th...

Embodiment 2

[0027] In this embodiment, the basic structure and implementation mode are the same as in Embodiment 1, and the differences are as Figure 4 , Figure 6 , Figure 7 Shown in: described feeding pipe 4 is provided with air intake pushing structure, and described air feeding pushing structure comprises main air pipe 14, and described main air pipe 14 is connected with some oblique air pipes 15, and oblique air pipe 15 is connected with unloading pipe 4 communicated, and the communication position between the inclined air pipe 15 and the feeding pipe 4 is at the lower part of the inclined air pipe 15 and above the pre-embedded position. The main air pipe 14 is used to connect air supply devices such as air pumps. During blanking, the air supply device supplies gas, and the gas is blown into and pressed into the lower part of the feeding pipe 4 through the inclined air pipe 15 to promote the ceramic ferrule 17. The assembly and connection precision of the ceramic ferrule 17 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com