Automatic picking and assembling machine and automatic picking and assembling method for small tile paster groups

A technology of small tiles and patches, applied in the direction of automatic packaging control, packaging, packaging protection, etc., can solve the problems of difficulty in placing in cartons, labor intensity of workers, low production efficiency, etc., to improve production efficiency and degree of mechanization, High-reliability blanking and packing, improving the effect of suction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

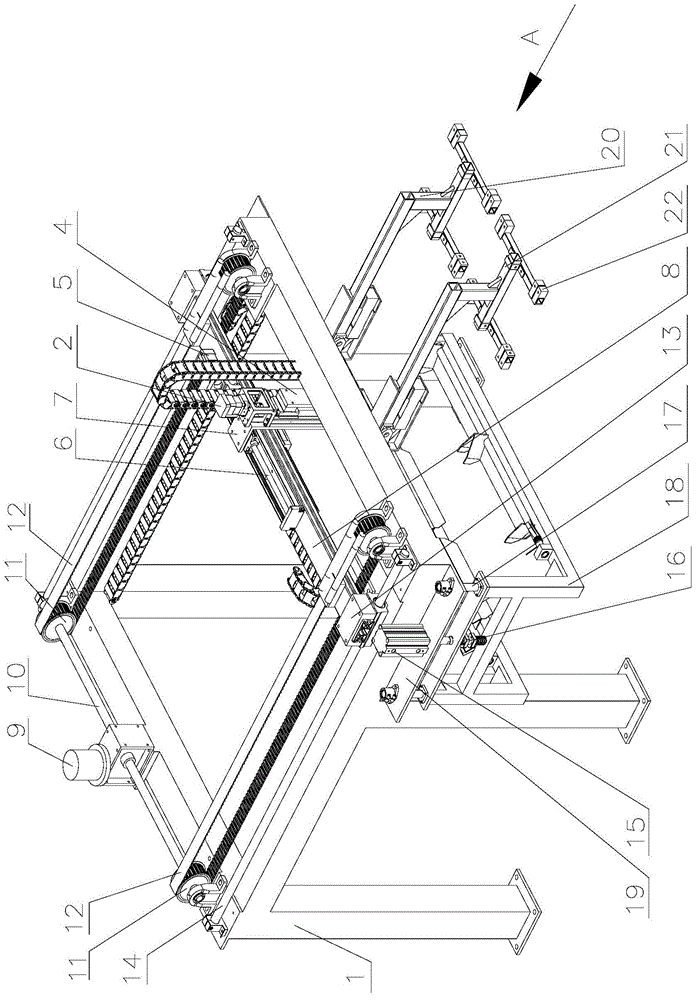

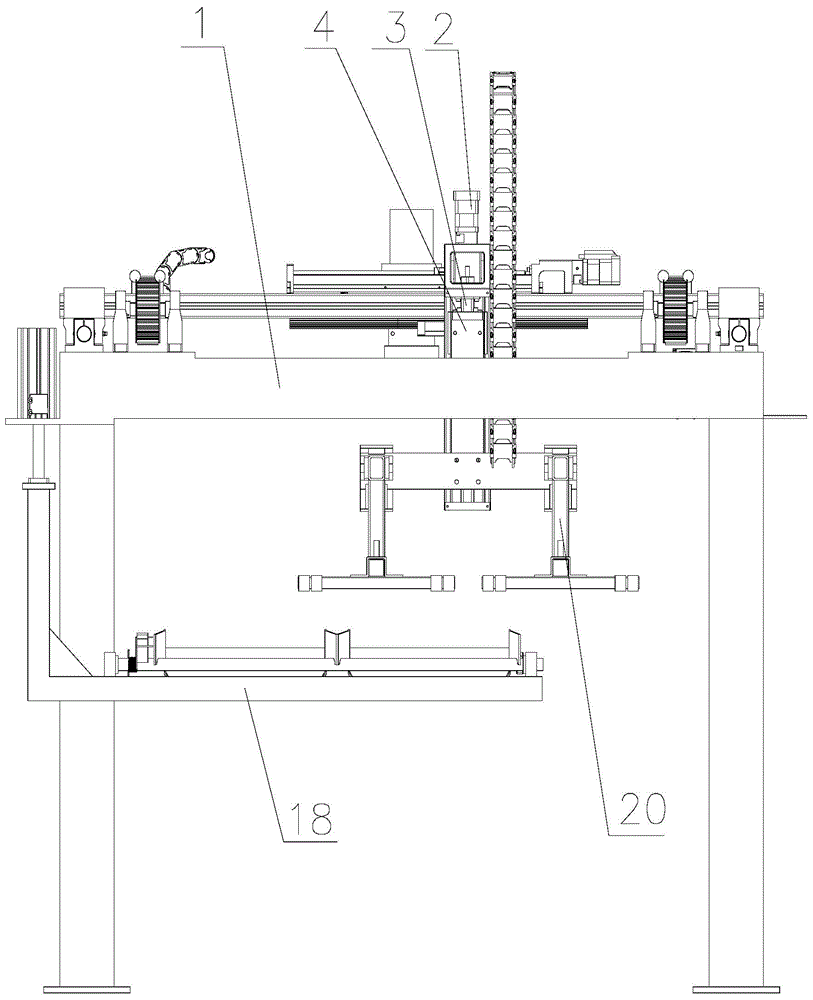

[0029] A kind of automatic loading and unloading machine that is used for small ceramic tile patch group in this embodiment, such as figure 1 or figure 2 As shown, it includes a support frame 1, a box support mechanism and a suction mechanism. The box support mechanism is set on one side of the support frame, and the suction mechanism is set above the box support mechanism; the suction mechanism is a three-axis manipulator structure, and the suction mechanism is connected with X-axis movement Mechanism, Y-axis moving mechanism and Z-axis moving mechanism.

[0030] Wherein, the Z-axis moving mechanism includes a Z-axis motor 2, a Z-axis screw 3 and a Z-axis slider 4, the output shaft of the Z-axis motor is connected with the Z-axis screw, and the Z-axis slider is threadedly connected with the Z-axis screw. Z-axis guide rails are respectively provided on both sides of the axis slider; one side of the suction mechanism is fixedly connected with the Z-axis slider, and the bracke...

Embodiment 2

[0043] This embodiment is an automatic loading and unloading machine for small tile patch groups. Compared with Embodiment 1, the difference is that a load cell is provided on the bracket of the suction cup group, and the suction mechanism is externally connected to the product detection system through the load cell. .

[0044] In this embodiment, an automatic loading and unloading method for a small tile patch group is realized by the above-mentioned loading and unloading machine, including the following steps:

[0045] (1) When the empty box used to pack the small tile patch group enters under the box-supporting mechanism, the box-supporting mechanism will fully open and position the empty box; below the box-supporting mechanism is the packaging area for qualified products, which is opposite to the supporting mechanism The lower side of the shelf is the storage area for non-qualified products;

[0046] (2) The suction mechanism moves to the small tile patch group and sucks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com