Pumping conveying vehicle

A technology for transporting cars and vehicles, which is applied in the field of suction equipment, which can solve problems such as time-consuming and power-consuming, inflexible structure, time-consuming and labor-intensive problems, and achieve the effects of avoiding dust and noise pollution, superior performance and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

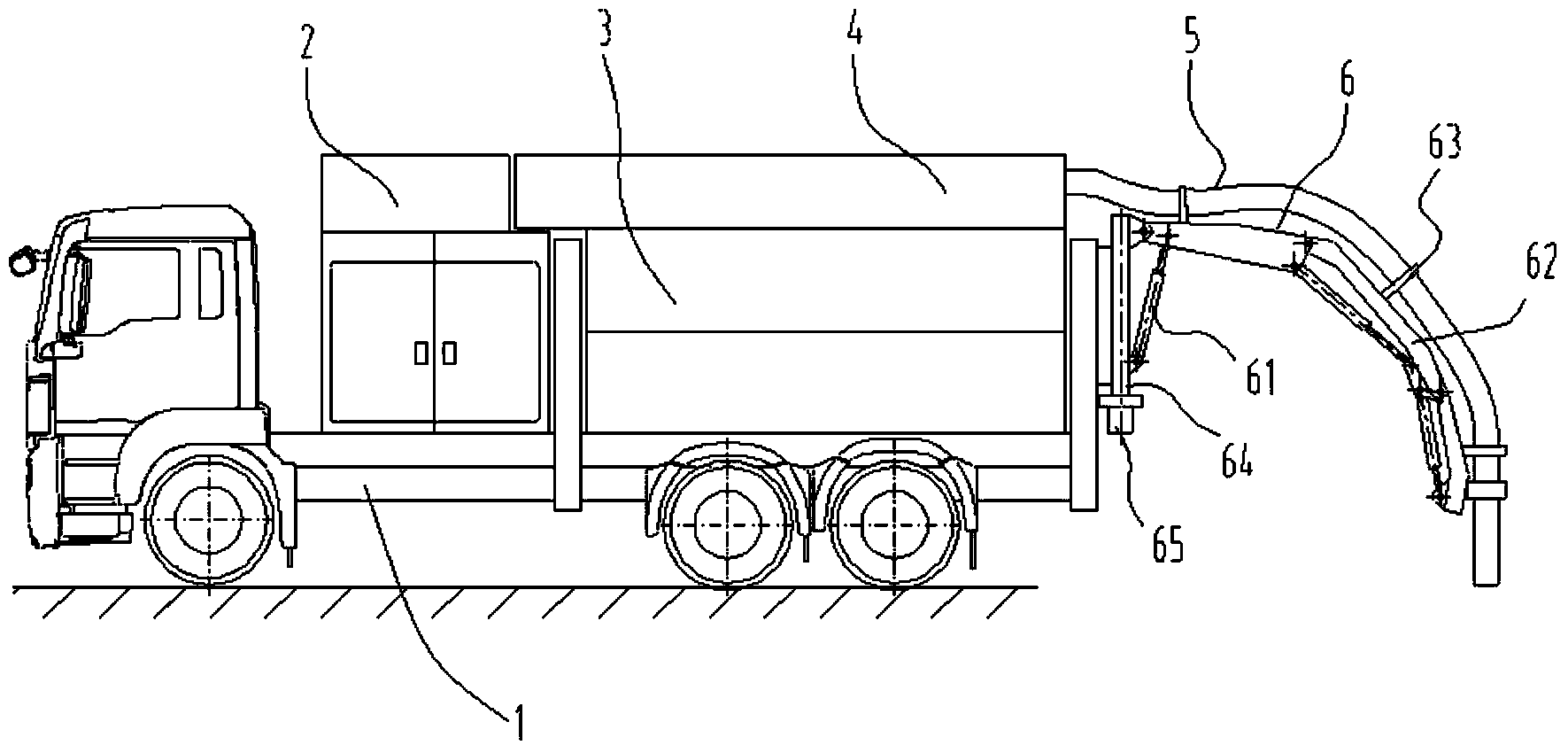

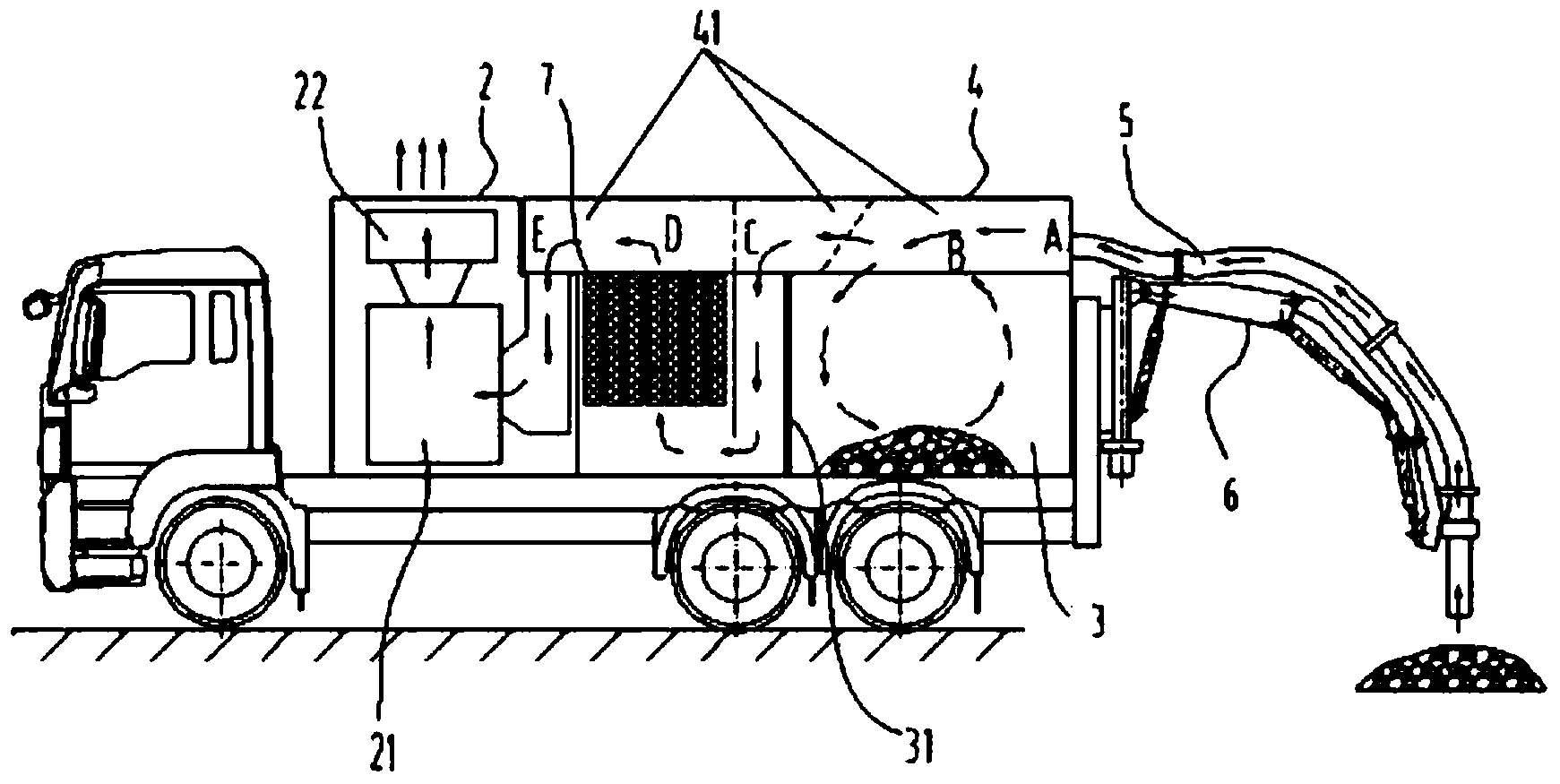

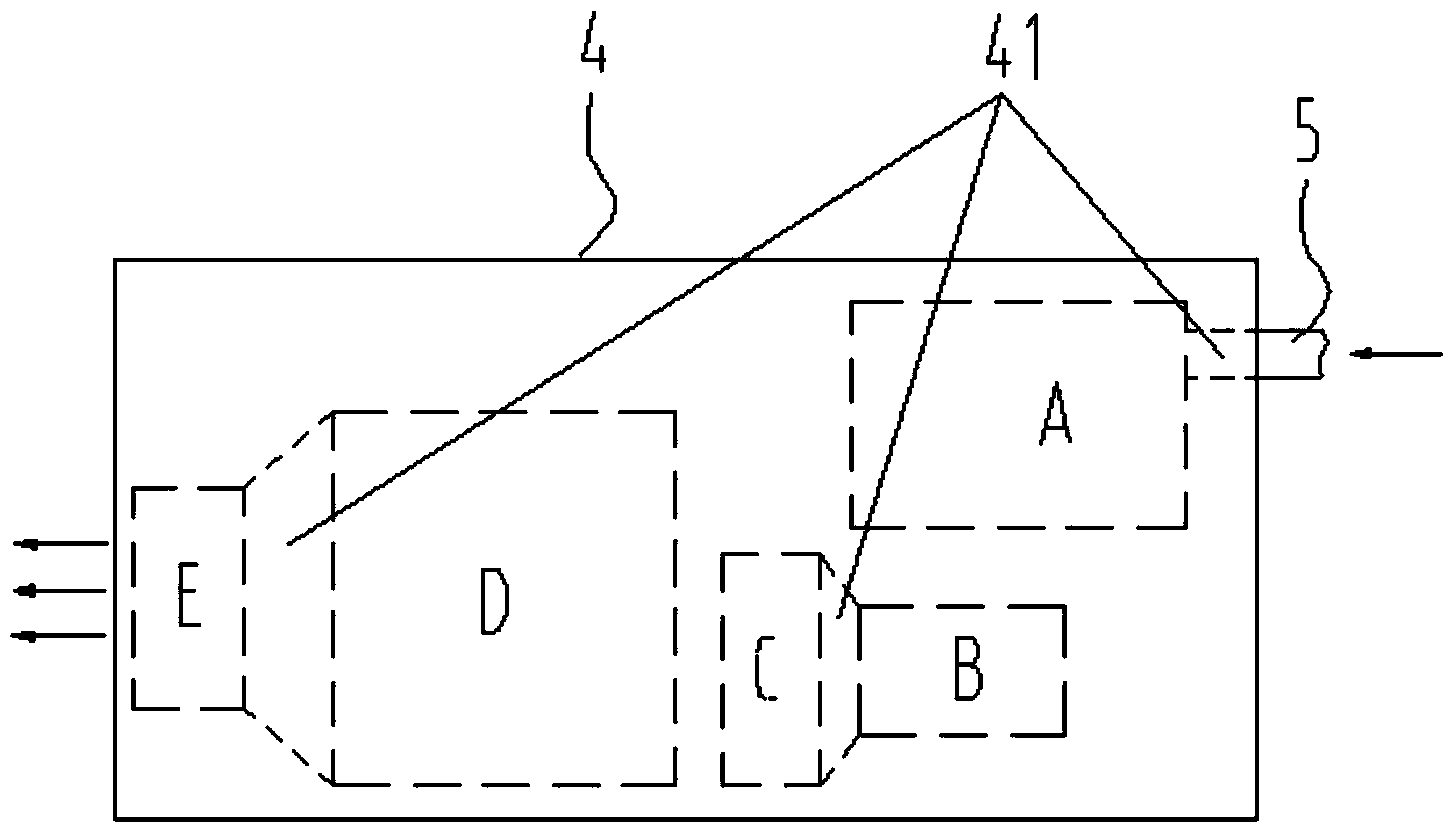

[0030] Such as figure 1 and figure 2 As shown, the present invention provides a suction vehicle, which is applied to the suction, transportation and unloading of materials. The suction vehicle includes a vacuum unit 2, a filter device 7, a storage bin 3, a suction Suction arm 6 and discharge device 8 (such as Figure 6 shown); the filter device 7 is respectively connected with the vacuum unit 2 and the storage bin 3; the top of the storage bin 3 is provided with an openable storage bin top cover 4, and the inside of the storage bin top cover There is a passage 41 for air flow transmission, which makes the filter device 7 communicate with the storage bin 3; the suction pipe 5 is attached to the suction arm 6, and is spatially positioned with the movement of the suction arm 6. One end of the pipe 5 is connected to the top cover 4 of the storage bin, and the other end is connected to the material to be sucked; the discharge device 8 is arranged on both sides or the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com