Transient unloading loose simulating system for excavating jointed rock mass

A technology for transient unloading, loosening, and jointed rock mass. It is used in material inspection products, soil material testing and other directions. It can solve the problem of slow unloading rate of unloading experimental system, unsatisfactory engineering unloading conditions, and joint rock model strain rate. lower problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

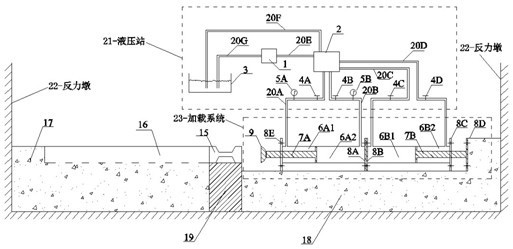

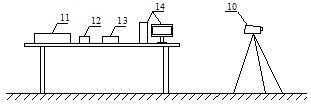

[0034] like figure 1 As shown, the present invention includes: a reaction pier (22), a jointed rock mass model, a test bench (17) provided with displacement scale marks, a transition block pad box (19), a pad box placed on the transition block pad box (19) Transition block (15), hydraulic station (21), loading device (23), loading device support table (18) and monitoring system.

[0035] Both the test platform (17) and the loading device support platform (18) are poured with high-strength concrete, such as Figure 7~8 As shown, the test bench (17) is 1.2m long, 0.5m wide, and 0.4m high, and a groove with a length of 1.0m, a width of 0.1m, and a height of 0.1m is arranged in the middle of the broad side of the upper surface of the test bench (17), for The jointed rock mass model is placed, and the width and height of the jointed rock mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com