Bottle unloading machine

A bottle machine and bottle technology, applied in the field of bottle unloading machine, can solve the problems of work efficiency and bottle unloading speed to be improved, and achieve the effect of compact structure layout, efficient cooperation, and firm structure of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

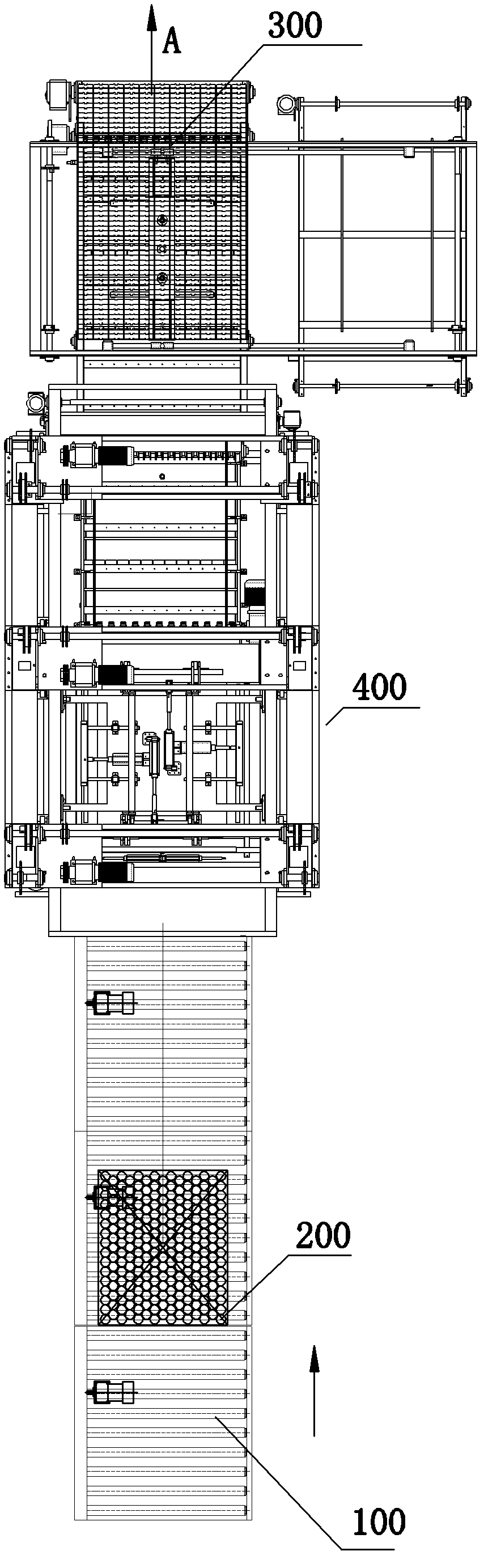

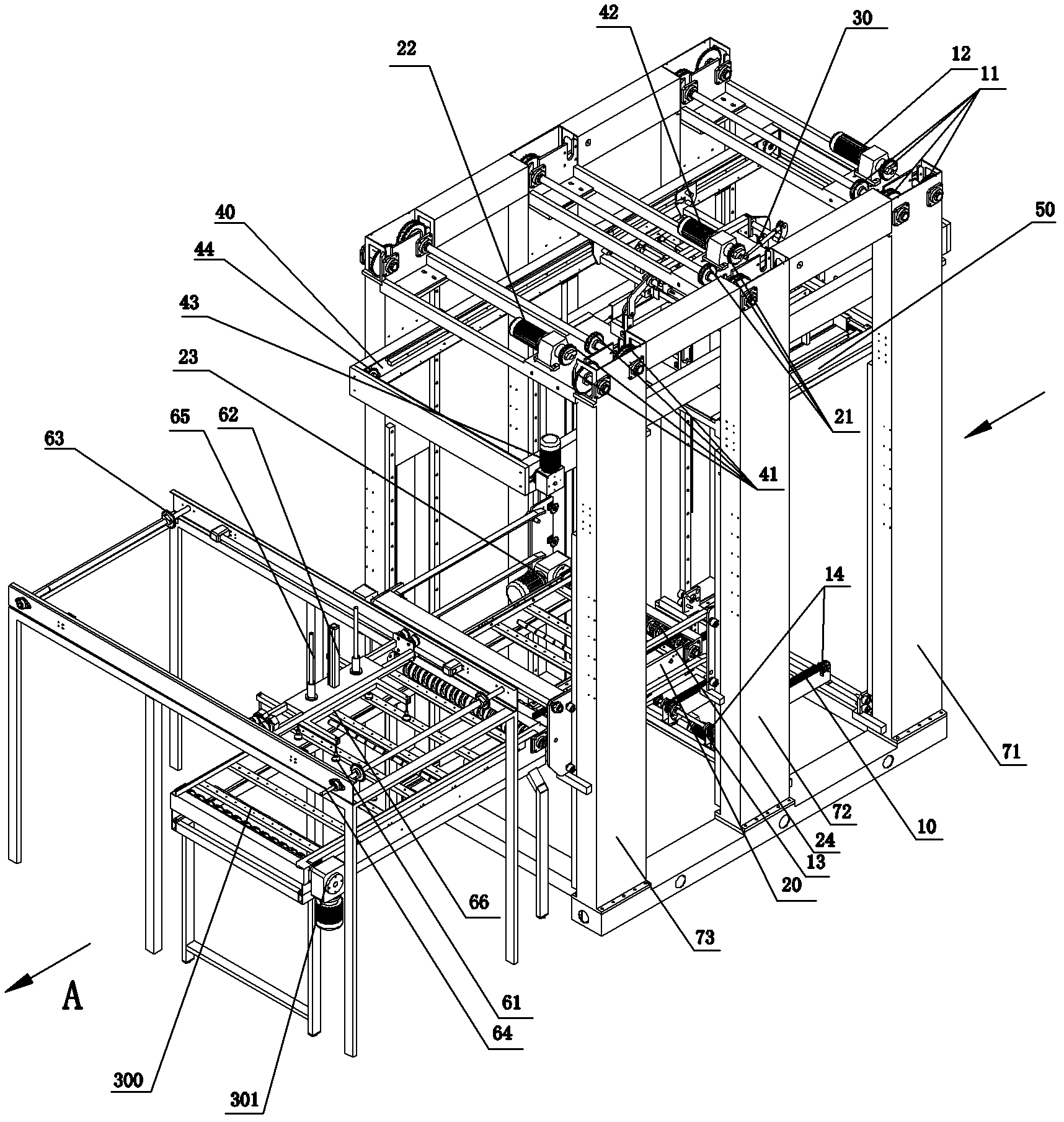

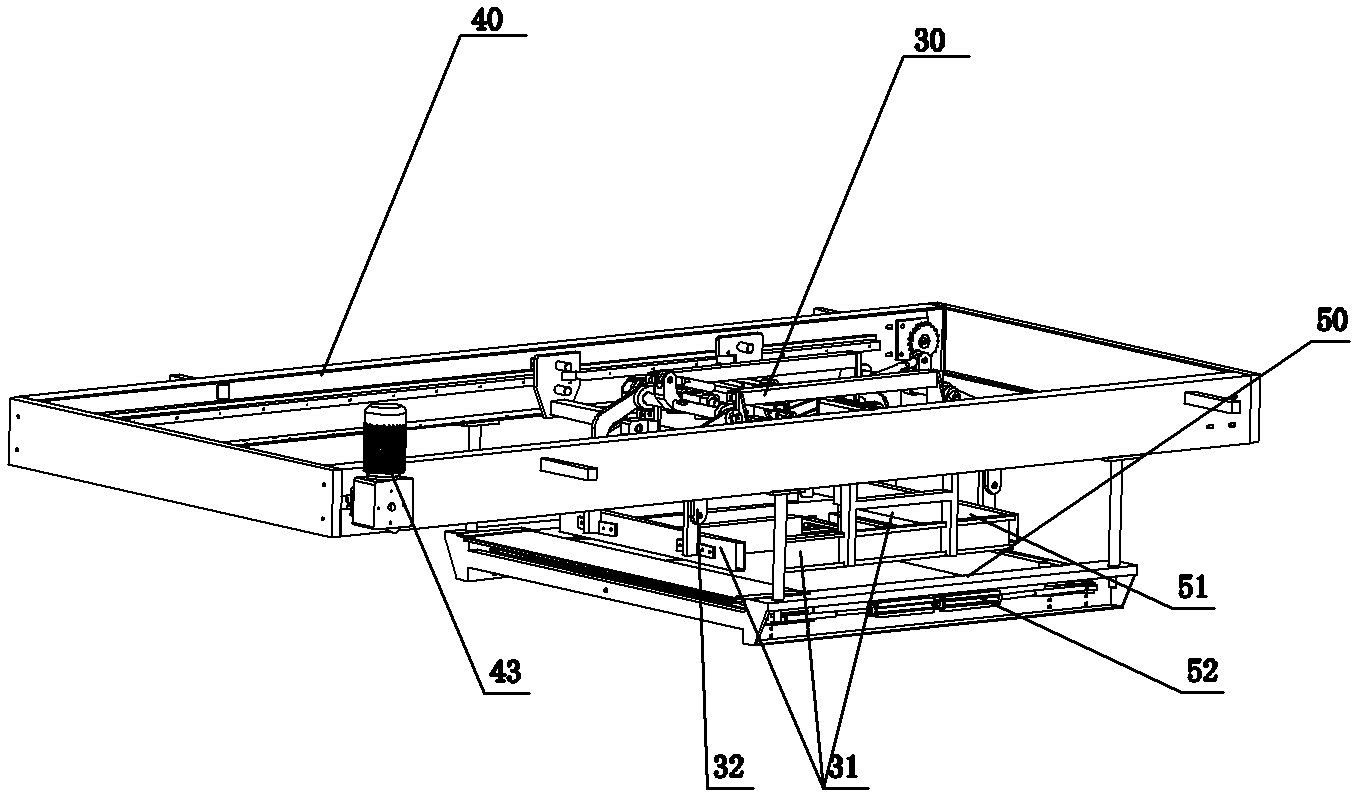

[0024] Refer to attached picture. The bottle unloading machine 400 provided by the present invention comprises:

[0025] The first platform carrying the whole stack of bottles, the first platform is connected with the first lifting transmission mechanism, and is a platform that can be lifted, and the first platform has a low working position that is equal to the working surface of the input conveying line 100; The input conveying line 100 refers to that the entire pile of bottles 200 is imported into the conveying device of the present invention, and its working surface refers to the side where the conveying device carries the whole pile of bottles 200. For example, if the conveying device is a roller type, the working surface is The upper surface of the roller table that carries the entire stack of bottles. Reference numeral 10 is the frame of the first platform, and the whole stack of bottles is formed by stacking several layers of bottles, the bottom of which is a pallet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com