Steel bar automatic feeding device

A technology for automatic feeding and bar material, which is used in measuring devices, analyzing materials, and testing the strength of materials by applying a stable bending force. It can solve the problems of low inspection efficiency, potential safety hazards, and inaccurate inspection results. Safety, accurate positioning, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

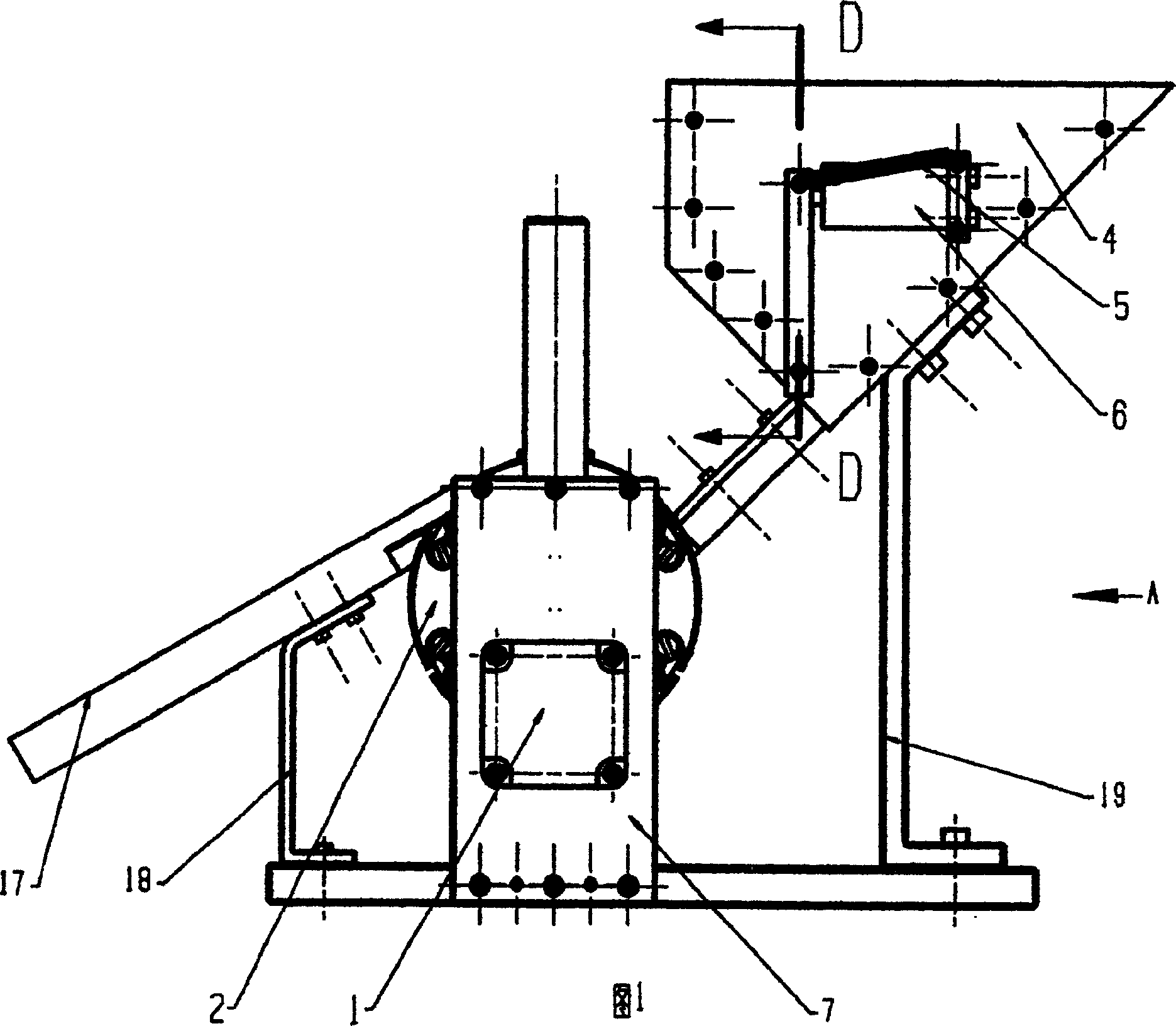

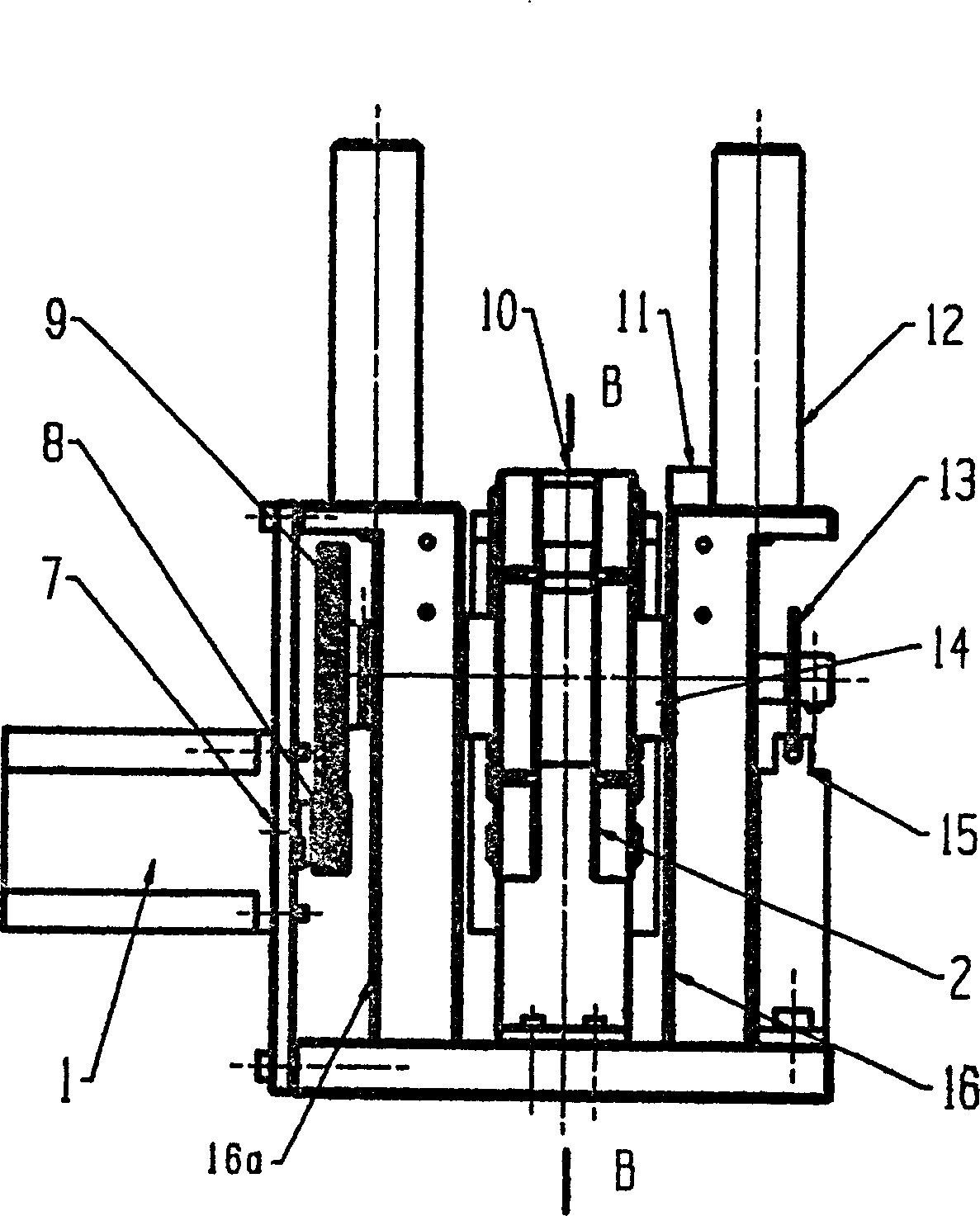

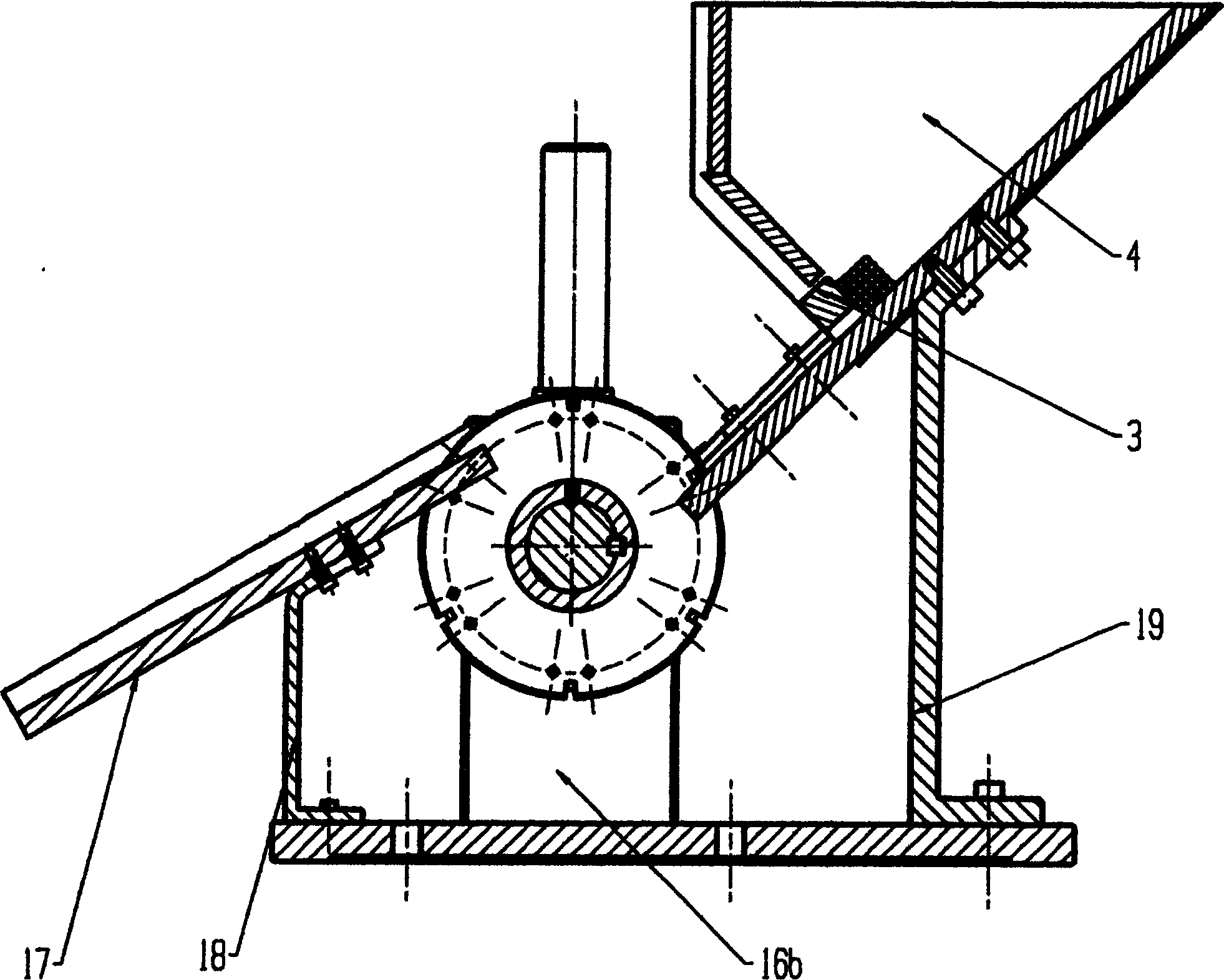

[0011] The bar material automatic feeding device of the present invention is composed of mechanical parts, pneumatic feeding parts and electrical control parts; as shown in Figure 1- Figure 4 As shown, the mechanical components include a hopper 4, a frame 16, a discharge port 17, and a rear support 19 and a front support 18 that support the hopper 4 and the discharge port 17 on the frame 16; the stepper motor 1 is fixed on the support plate 16c On the top, the output end faces the inside of the frame 16 and the gear 8 is installed. The shaft 14 passes through the left and right brackets 16a, 16b and is fixed on it. The gear 9 is fixed on the shaft 14, and is close to the outer end of the left bracket 16a and meshes with the gear 8. The feeding turntable 2, the station disk 13 and the gear 9 are coaxially arranged, and the station disk 13 is fixed on the shaft 14, close to the outer end of the right bracket 16b; the left bracket 16a or the right bracket 16b is designed to recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com