Multi-station automatic knife sharpening equipment

An automatic sharpening and multi-station technology, applied in metal processing equipment, grinding/polishing equipment, other manufacturing equipment/tools, etc., can solve problems such as difficulty in meeting design requirements, poor precision, and low efficiency, and achieve high efficiency The effect of automatic uninterrupted feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described in detail below with reference to the embodiments and the accompanying drawings.

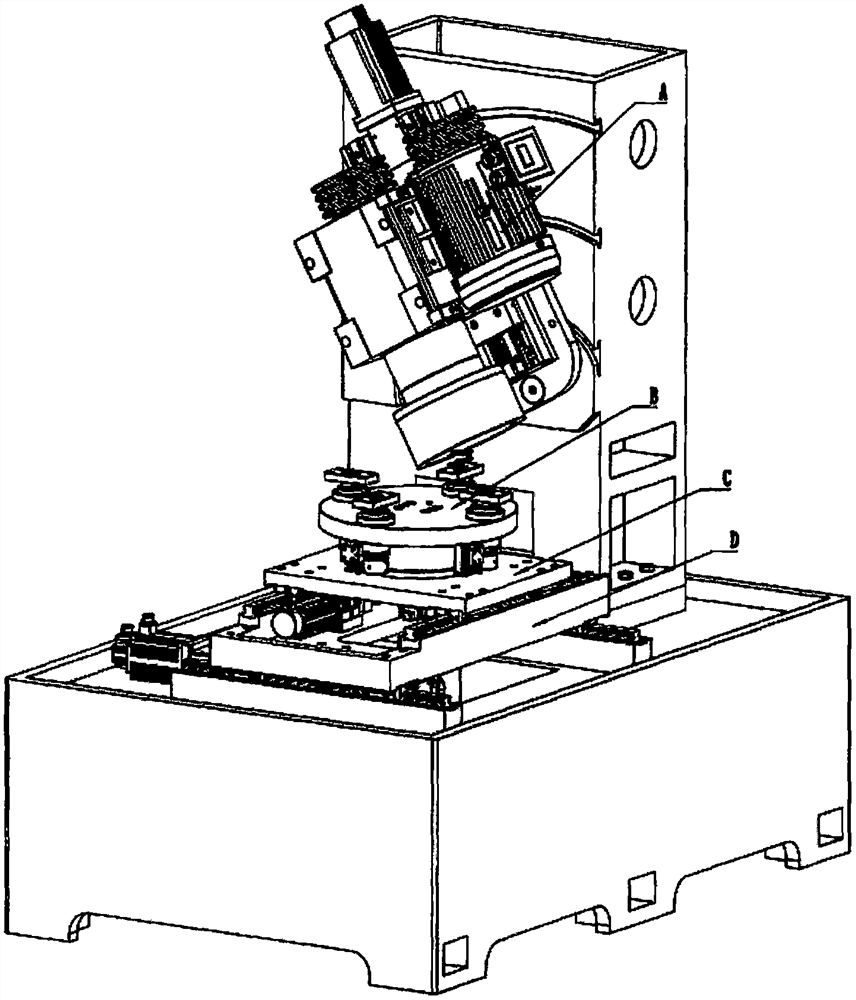

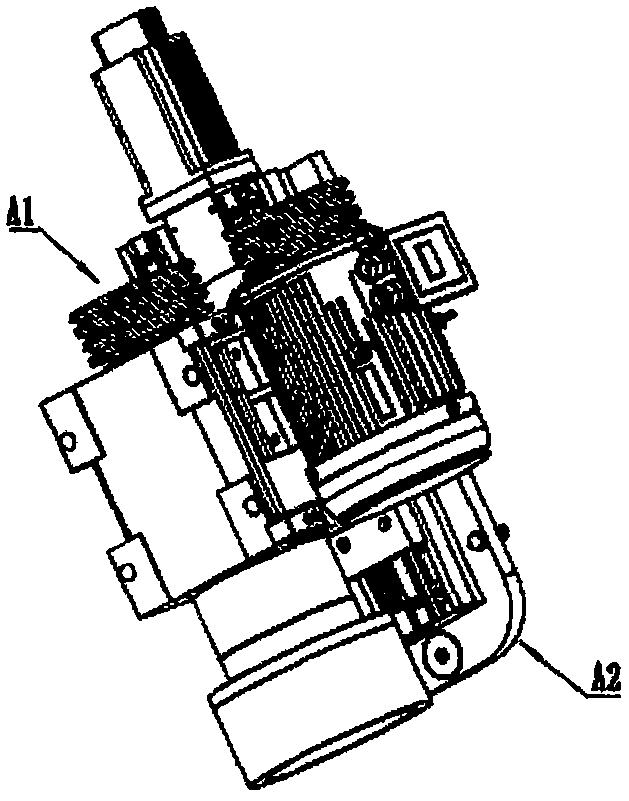

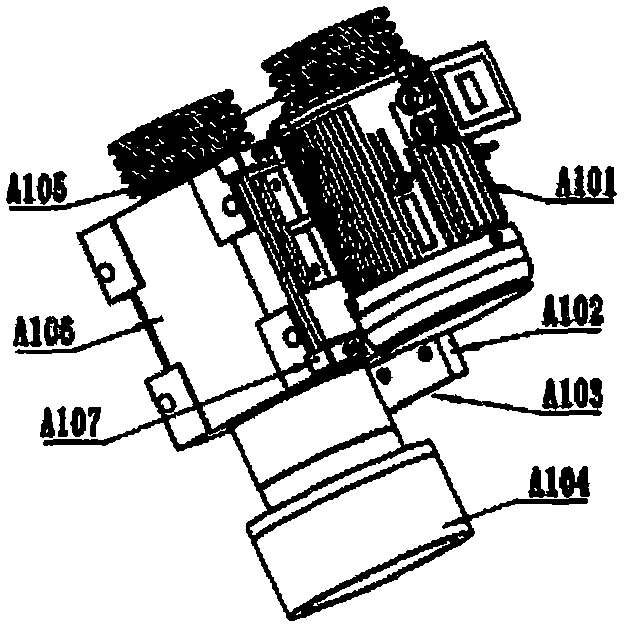

[0067] see Figure 1-Figure 45 , a multi-station automatic knife sharpening equipment, including grinding head assembly A, main turntable assembly B, longitudinal sliding table assembly C, transverse sliding table assembly D and five-axis bed E, due to the different blade edge widths, the sharpening The rotation angle of the grinding head assembly A is also different and needs to be set in advance;

[0068] The five-axis bed E includes a column E1, a grinding head corner support bearing E2, a grinding head corner support shaft E3, a lateral slide guide rail E4 and a lateral slide drive module E5; the grinding head corner support shaft E3, one end is supported by the grinding head corner The inner hole of the bearing E2 is tightly matched, and the other end is fixed on the column E1 of the five-axis bed;

[0069] The grinding head assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com