Novel self-dumping car with axle load of 27t

A self-dumping and wagon technology, applied in the field of railway wagons, can solve problems such as unsatisfactory self-dumping, achieve the effects of solving lubrication difficulties, prolonging the maintenance cycle and life, and improving the economic benefits of transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

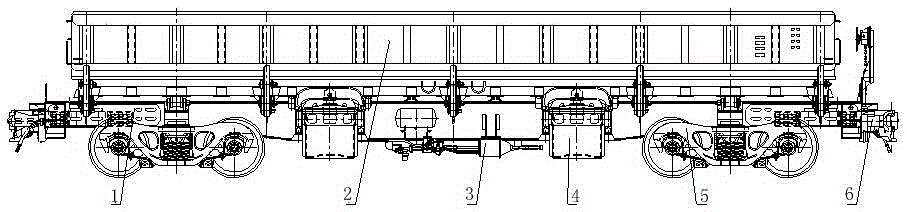

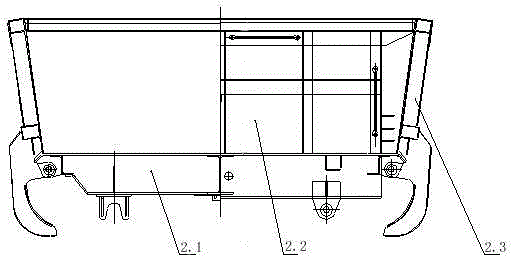

[0025] A 27t-axle re-type self-dumping car, including an underframe component 1, a carriage component 2, a wind hand brake device 3, a tipping device 4, a coupler buffer device 5, and a bogie 6, and the two ends of the underframe component 1 are equipped with bogies 6. The carriage composition 2 is arranged on the upper side of the chassis composition 1, two rows of wheels are respectively arranged on the lower sides of the left and right ends of the chassis composition 1, and a coupler buffer device 5 is arranged between the two rows of wheels. A wind hand braking device 3 for braking is provided, and a tipping device 4 capable of tipping the carriage composition is provided between the underframe composition 1 and the carriage composition 2.

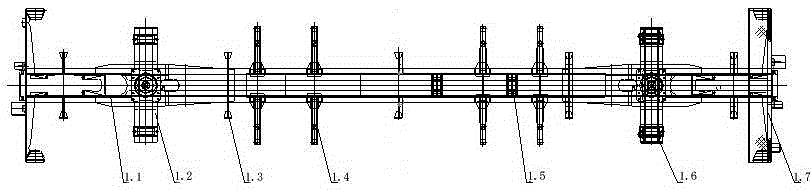

[0026] The underframe composition 1 includes a bottom beam 1.1. The bottom beam 1.1 is a box-shaped fish-belly structure welded by H-shaped steel and upper and lower cover plates. The bottom beam 1.1 is equipped with a corbel 1.2 for in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com