Rotary compressor

A technology of rotary compressors and compression mechanisms, applied in the direction of rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of processing difficulty, cost increase, and insufficient effect, and achieve simple and reasonable structure and wide application range Wide range and high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

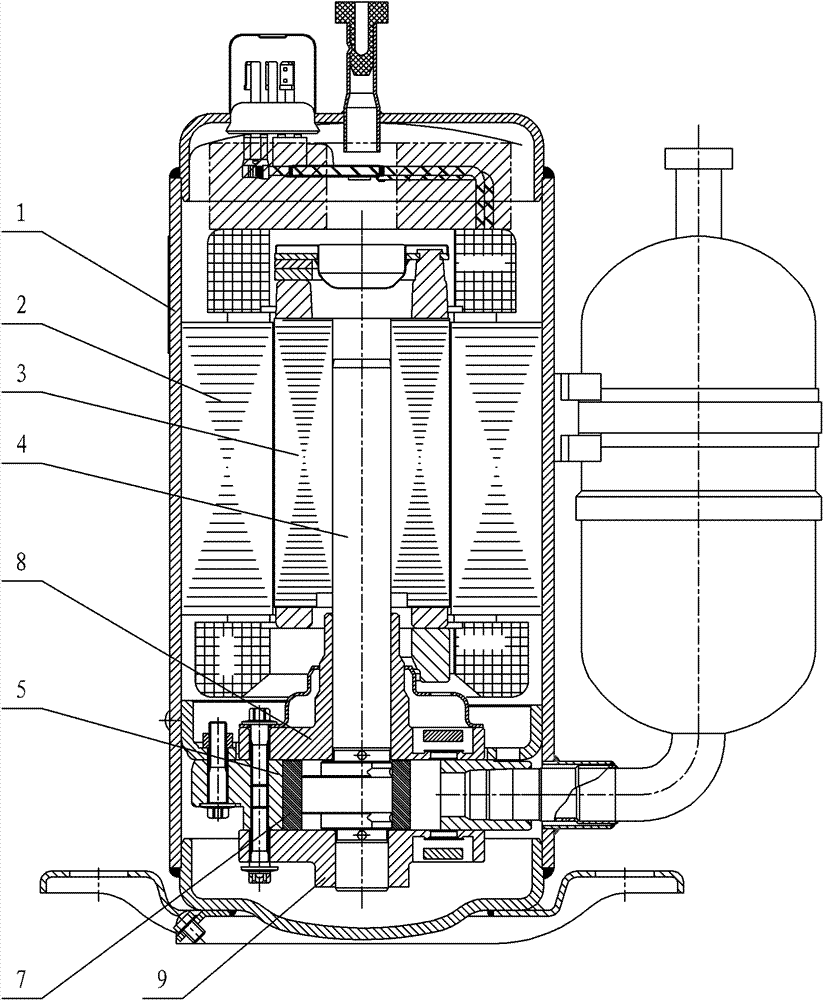

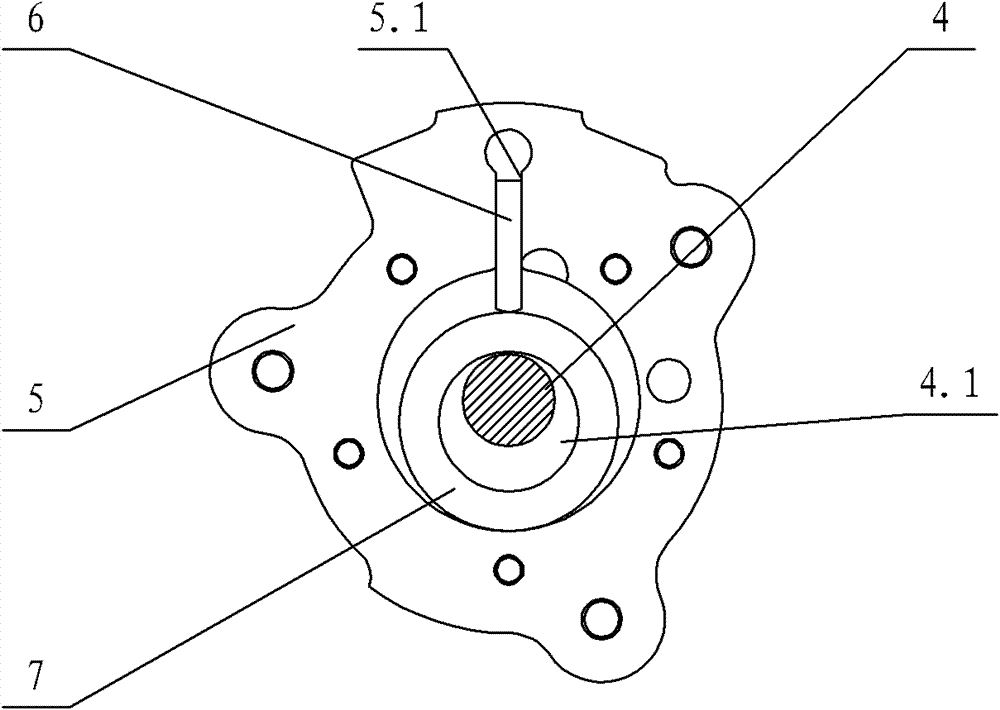

[0022] see image 3 , the rotary compressor includes a housing 1, a motor and a compression mechanism are arranged in the housing 1; the motor includes a stator 2 and a rotor 3, the stator 2 is fixed to the inner wall of the housing 1, and the rotor 3 is connected to the crankshaft 4 in the compression mechanism Connected, the compression mechanism also includes a cylinder 5, the cylinder 5 is provided with a slide groove 5.1 for accommodating the slide 6 and a piston that is sleeved on the outer circumference of the eccentric shaft 4.1 of the crankshaft 4 and rotates with the crankshaft 4 to compress the refrigerant, and the slide The front end of 6 is in contact with the outer circumference of the piston. The main bearing 8 and auxiliary bearing 9 for supporting the crankshaft 4 are arranged on the upper and lower sides of the cylinder 5. The piston includes a large piston ring 7.1 and a small piston ring 7.2 arranged concentrically, and a small piston ring 7.2 Set on the ou...

no. 2 example

[0026] see Figure 4 , In this embodiment, the front end of the sliding plate 6 is provided with a needle roller 6.1, and the needle roller 6.1 is in contact with the outer periphery of the large piston ring 7.1.

[0027] The purpose of this embodiment is to change the sliding friction between the front end of the sliding plate and the outer periphery of the large piston ring 7.1 into rolling friction, but there is a problem here. If the existing rotary compressor design of one piston is adopted, this method cannot achieve the desired result. Effect, because the relative linear velocity between the existing piston and the front end of the slider is very high, and the outer circumference of the needle roller is limited by the width of the front end of the slider, so that the speed of the needle roller rotation is too high, resulting in The power consumption loss of the rotation of the needle roller is worsened, and the reliability of the needle roller is reduced; because this t...

no. 3 example

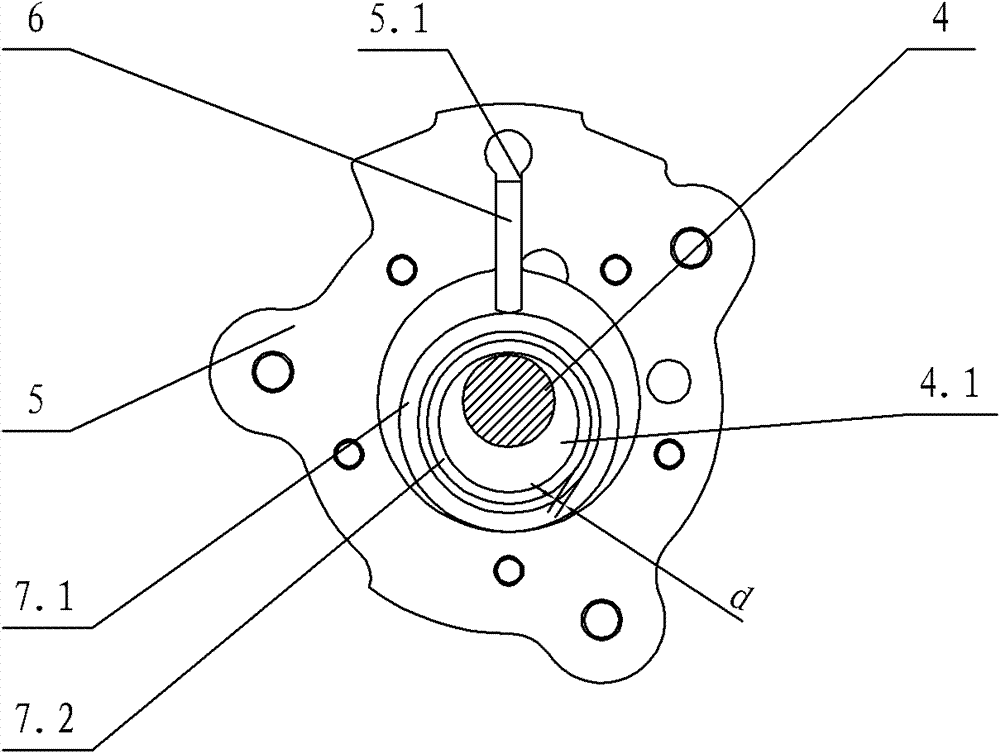

[0030] see Figure 5-Figure 6 , In this embodiment, a groove 7.11 is provided on the outer periphery of the large piston ring 7.1, and the front end of the sliding plate 6 is embedded in the groove 7.11.

[0031] In this embodiment, the front end of the sliding plate is nested in the groove 7.11 on the outer circumference of the large piston ring 7.1. The purpose of this design is to make the sliding plate follow the large piston ring 7.1, and there is no high speed between the two. At the same time, the front end of the sliding plate is in close contact with the large piston ring 7.1, and the refrigerant leakage at the contact point can be optimized, thus improving the energy efficiency of the compressor. To the expected effect, because there is no relative sliding between the single piston and the sliding plate, the single piston has no self-rotation, and the linear velocity between the inner circumference of the single piston and the eccentric shaft of the crankshaft will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com