Test bed for hydraulic brake actuating mechanism

A technology of hydraulic brakes and actuators, which is applied in the testing of machines/structural components, testing of mechanical components, electrical testing/monitoring, etc. It can solve problems such as the response quality of actuators and the difficulty of precise control that have rarely been studied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

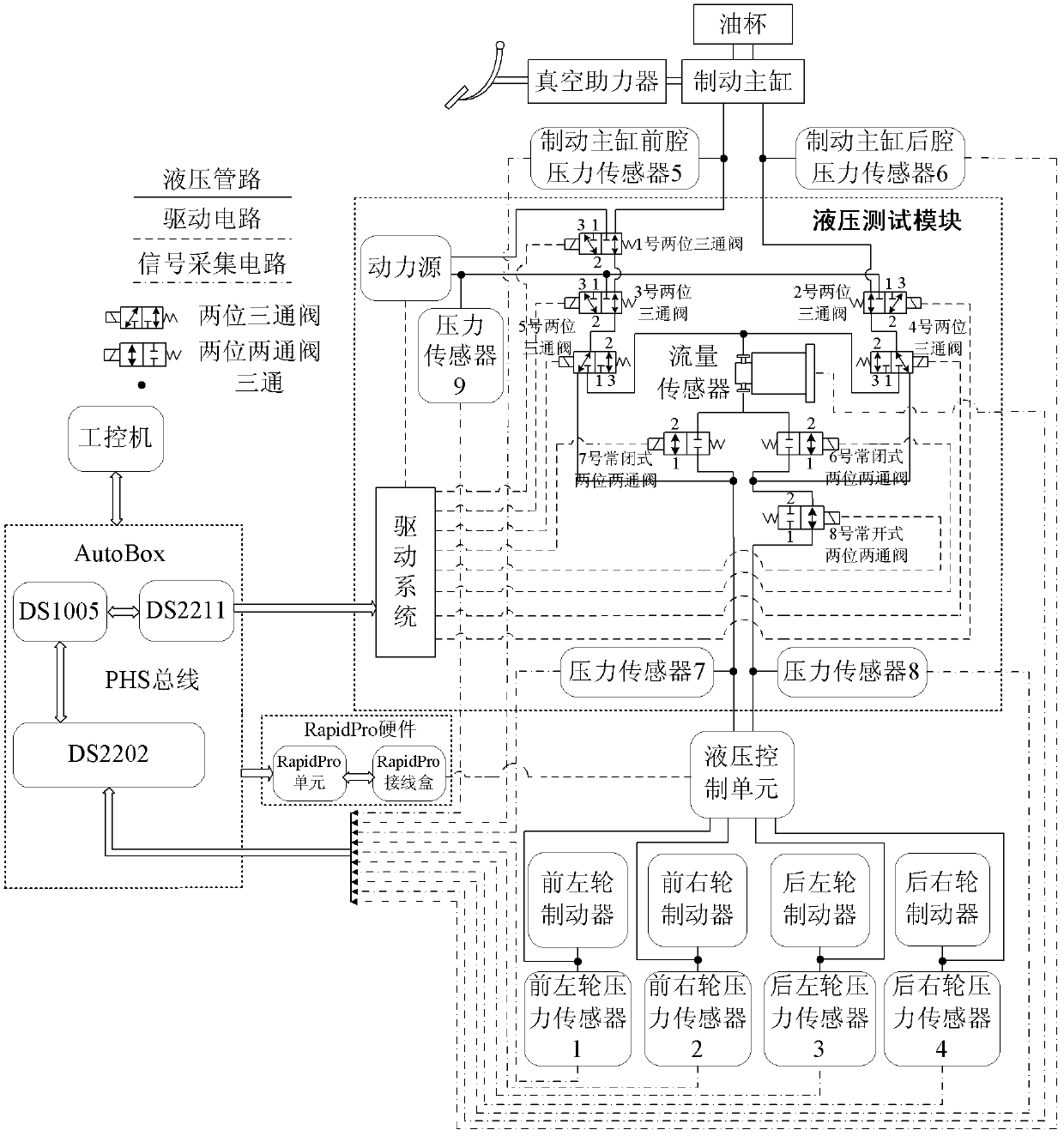

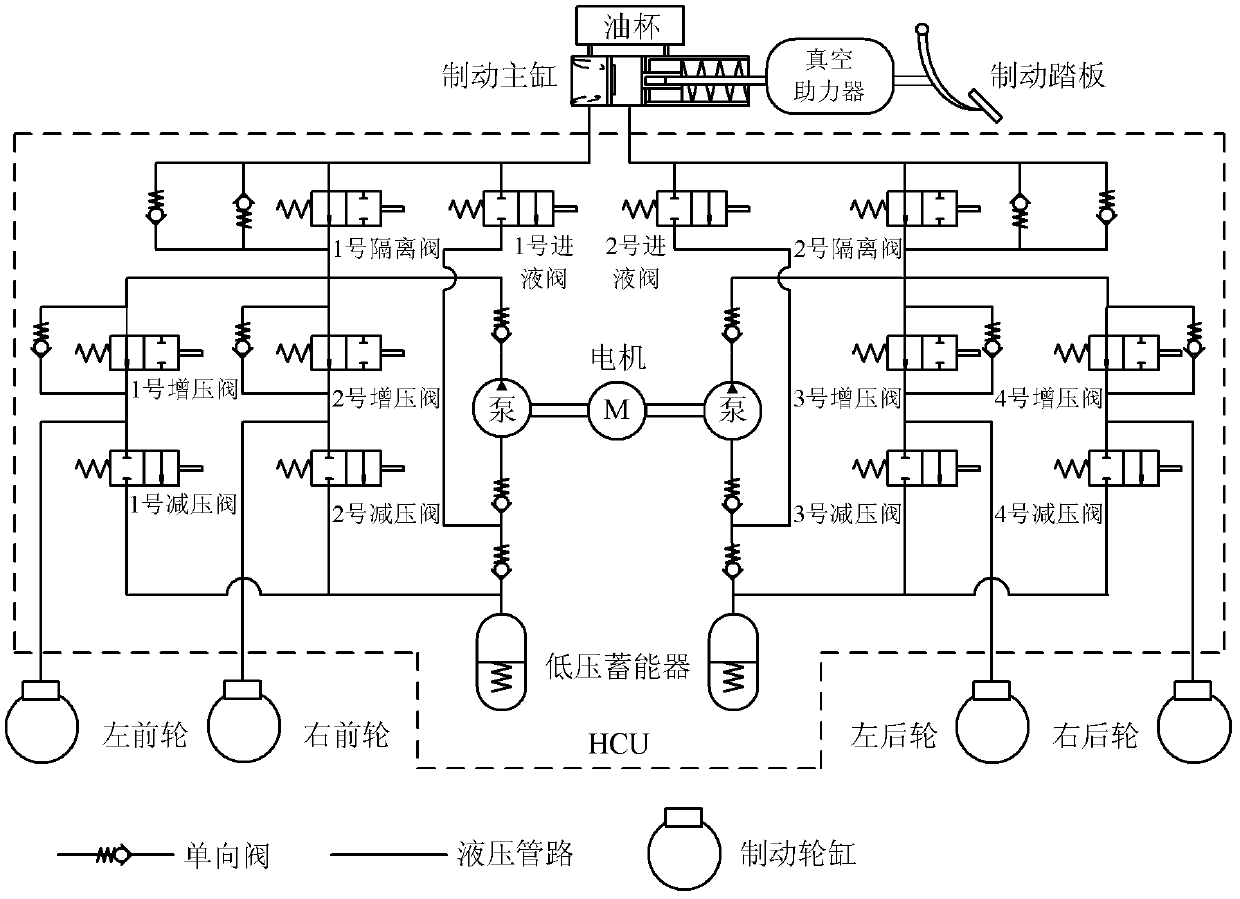

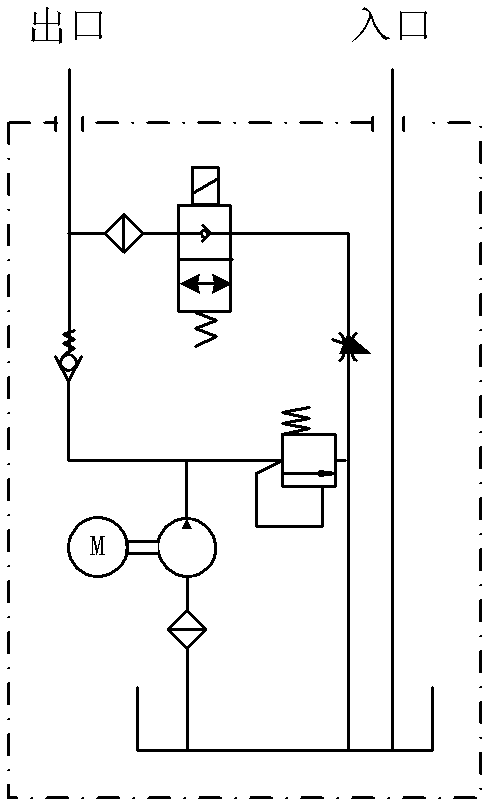

[0025] refer to figure 1 , The invention provides a hydraulic brake actuator test bench. The technical problem to be solved by this test bench is that the actuator test bench provided can carry out dynamic response test and static response test on the main components of the hydraulic control unit; the hydraulic test module of this test bench has good portability, and can easily test different The hydraulic braking system is tested.

[0026] In order to solve the above-mentioned technical problems, the present invention utilizes MATLAB / Simulink and dSPACE (Digital Signal Processing and Control Engineering) real-time simulation system to independently develop a hydraulic brake actuator test bench. This test bench is composed of real-time platform, ICC hydraulic brake system and hydraulic test module.

[0027] 1. Real-time platform

[0028]The real-time platform of hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com