Field test system for transfusion, stress and deformation coupling characteristics of jointed rock mass

A technology of fractured rock mass and field test, applied in the field of rock mass seepage characteristics research, can solve the problem of insufficient geometric representation of fracture surface, inability to fully reflect fracture roughness, initial gap width filling, lack of field fracture rock mass seepage, stress Coupling test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

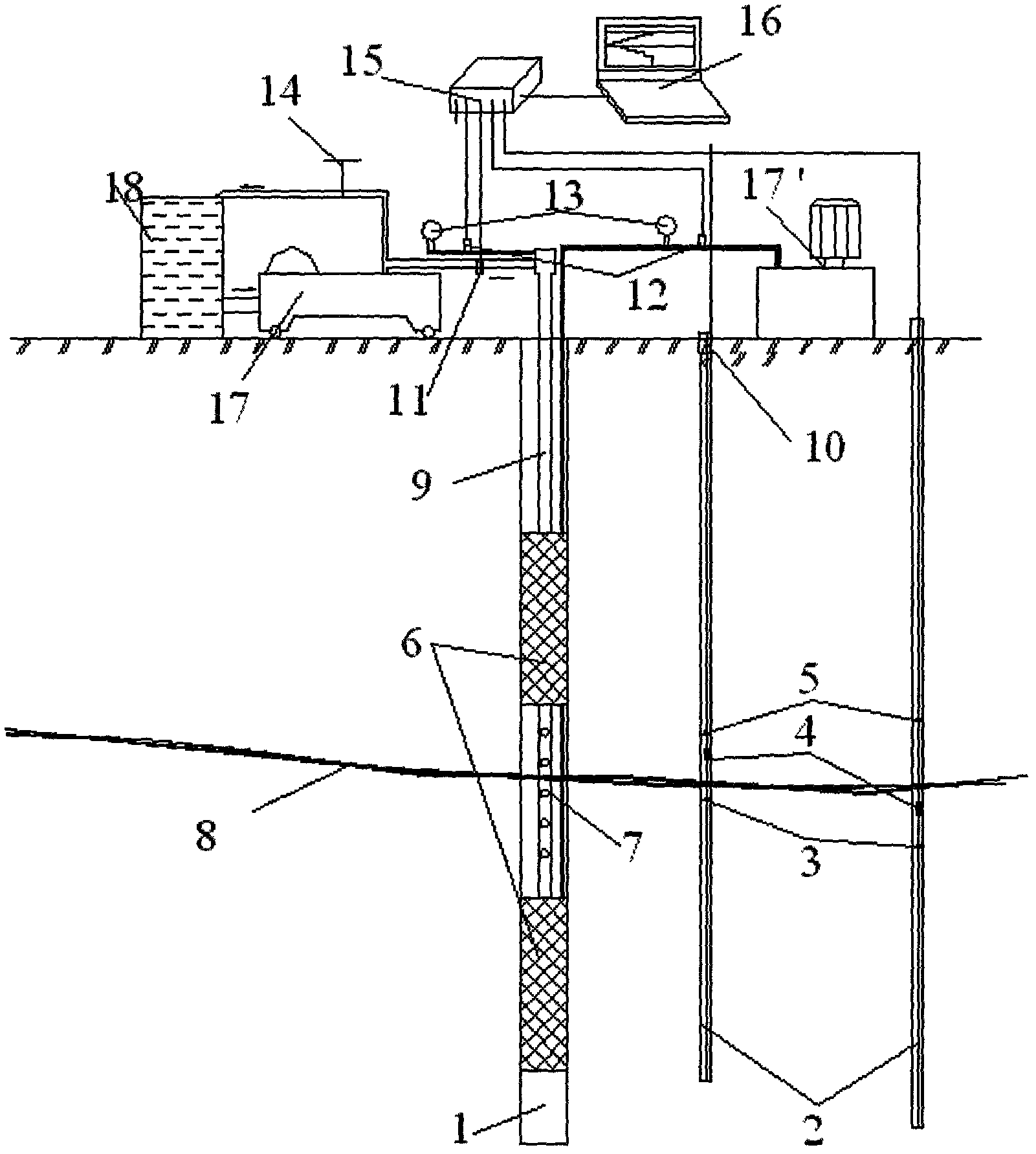

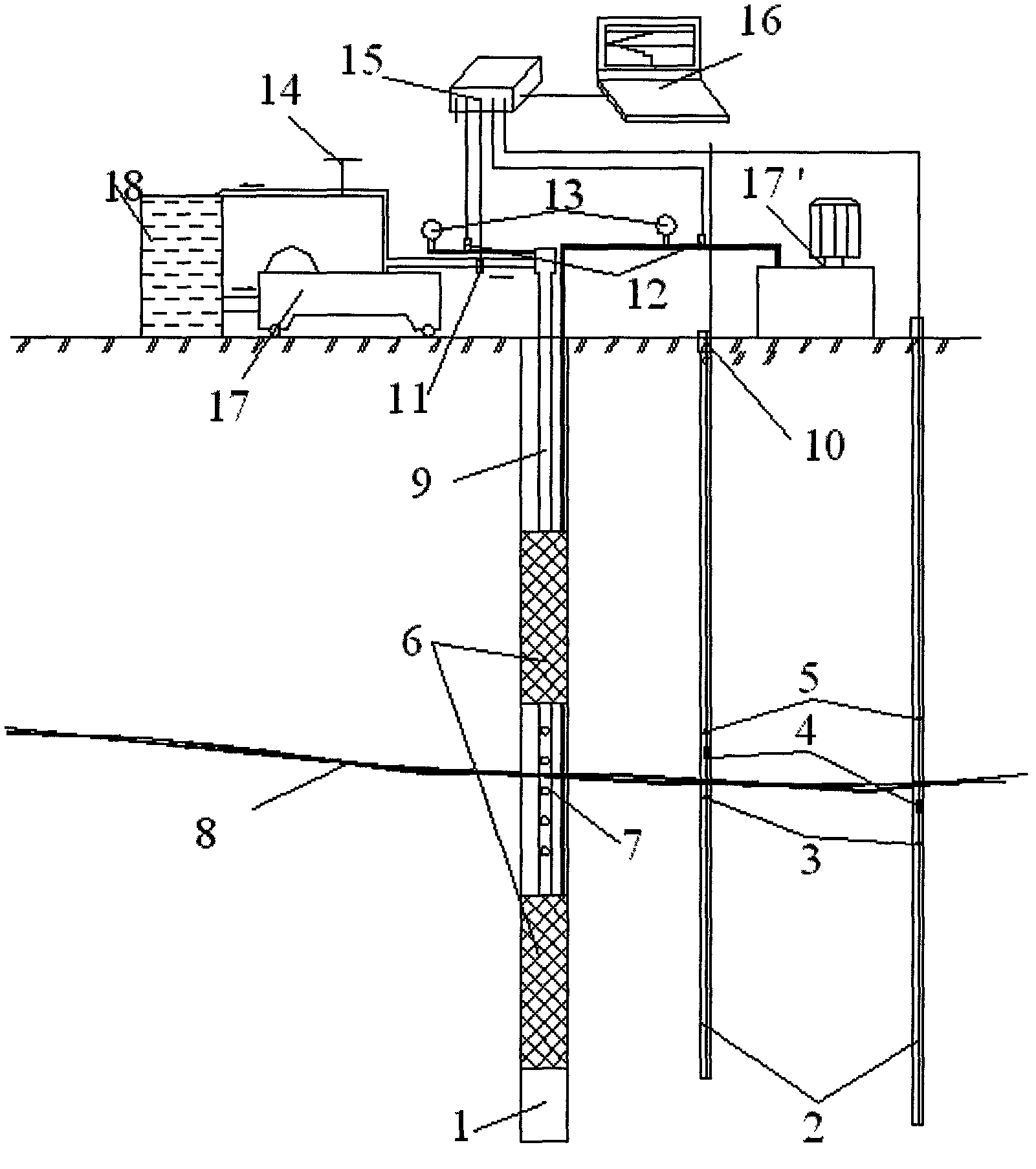

[0021] The invention relates to a fissure rock mass seepage, stress, and deformation coupling characteristic field test system, which includes simultaneous measurement and data collection and storage of seepage pressure, seepage flow rate, and stress-deformation displacement of the fissure rock mass permeability high-pressure hydraulic test.

[0022] See figure 1 , one A field test system for the coupling characteristics of seepage, stress and deformation of fractured rock mass. In the field exploration of flat caverns, the distribution characteristics of rock mass fractures are studied through fracture description, measurement and statistical analysis. According to the grouping of fractures, select specific fractures for experimental research. In the selected area, the fractures are not easy to develop too much. In 8 places where there are single f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com