Exhaust device used for hydraulic test of pressure vessel

A pressure vessel and hydraulic test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of increasing the weight of the container, time-consuming and labor-intensive, complicated operation, etc., to avoid potential safety hazards , Wide application prospects, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

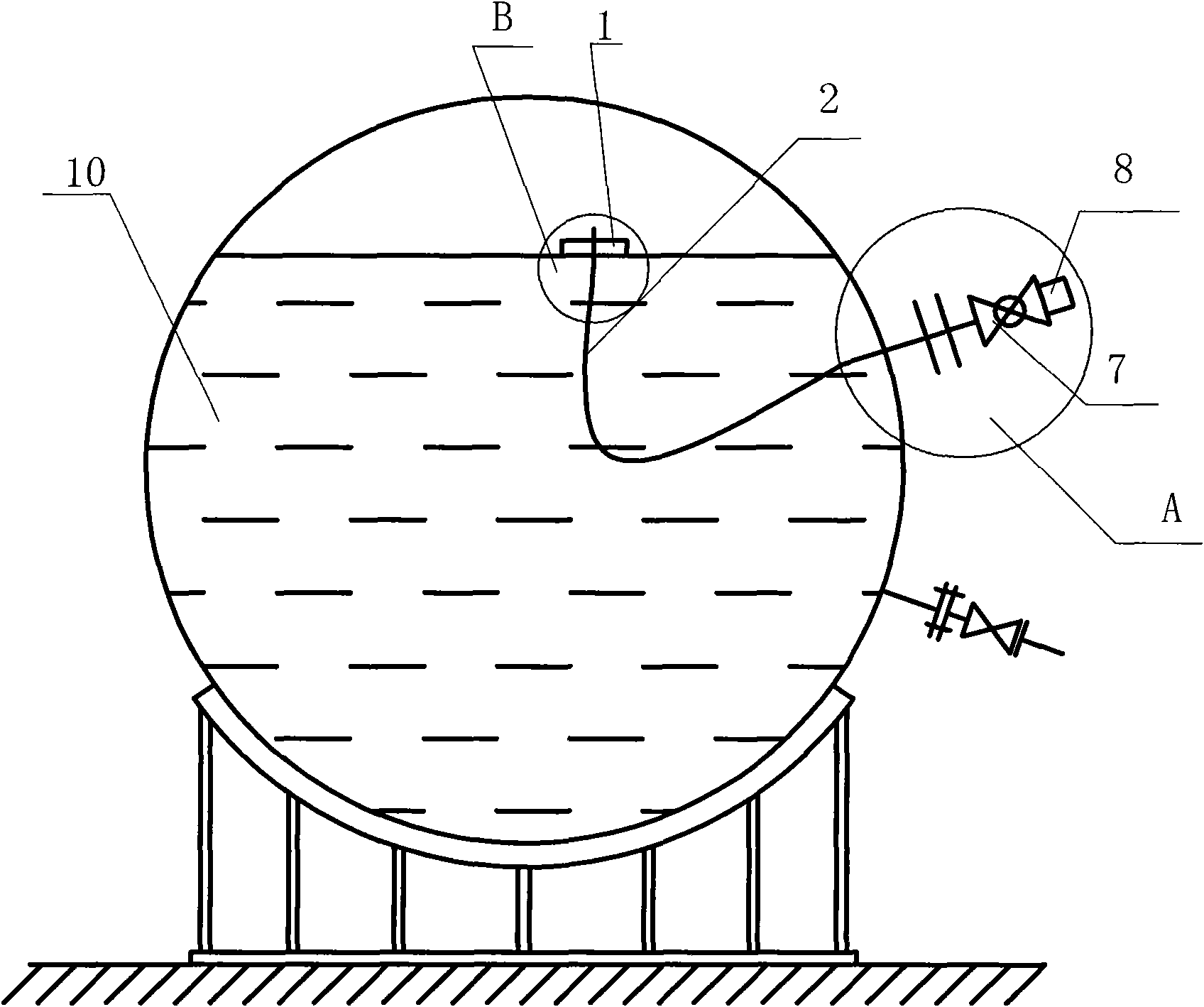

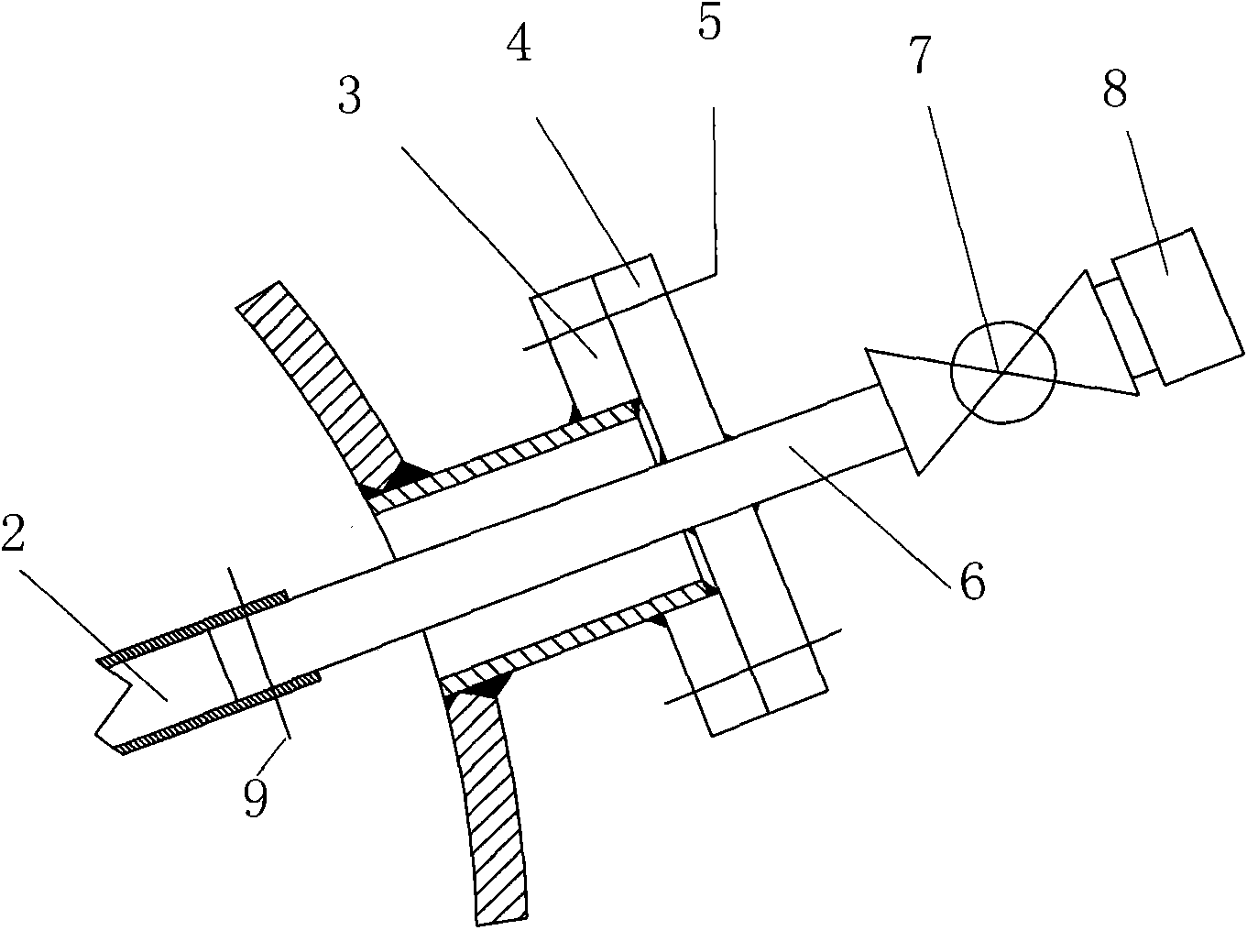

[0023] Such as figure 1 , figure 2 and image 3 As shown, the exhaust device for the hydraulic pressure test of the pressure vessel includes: a floating member 1 made of foam plastic, an exhaust pipe 2, a stop valve 7, a connecting pipe 6, a connecting flange 3 and a blind plate 4.

[0024] in,

[0025] Exhaust pipe 2 adopts a fabric-reinforced plastic hose with characteristics such as lightness, softness, pressure resistance, and torsion resistance;

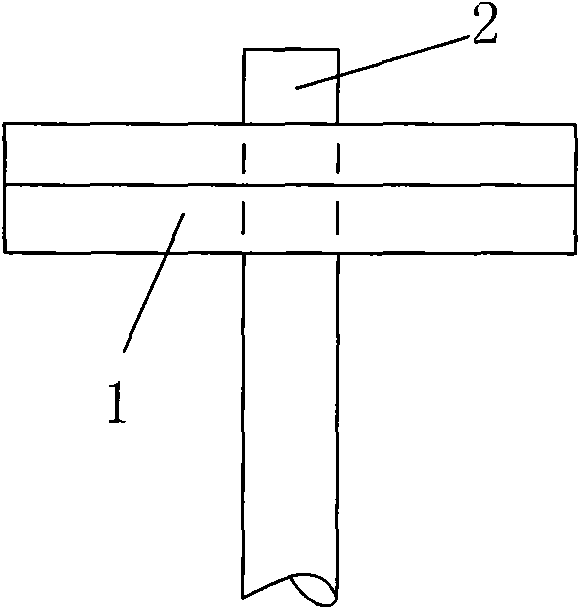

[0026] Such as image 3 As shown, the floating part 1 is formed by superimposing two foam blocks with a thickness of 45mm and an area of 400x400mm. One end of the above-mentioned plastic hose is fixed on the floating part 1 and passes through the floating part 1;

[0027] The connecting pipe 6 is a metal pipe, and the other end of the exhaust pipe 2 is sleeved on the connecting pipe 6, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com