Pipeline hydraulic test device

A hydraulic test and pipeline technology, applied in the direction of applying stable tension/pressure to test the strength of materials, using liquid/vacuum to measure liquid tightness, etc., can solve problems such as high cost, high cost of production line equipment, and large capital investment , to achieve the effect of good effect and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the content of the present invention more obvious and understandable, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

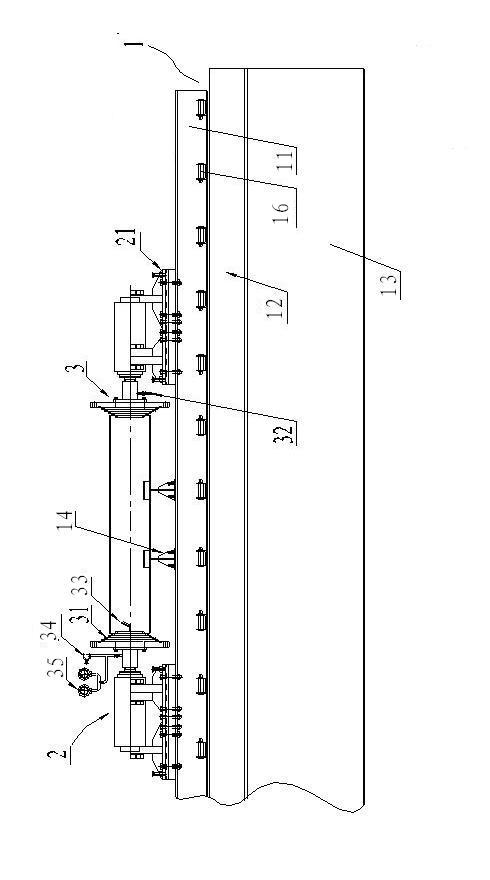

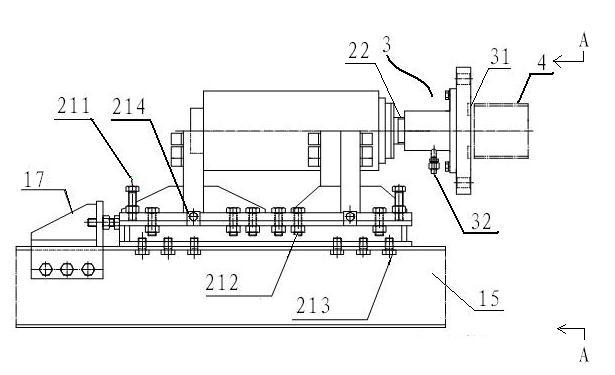

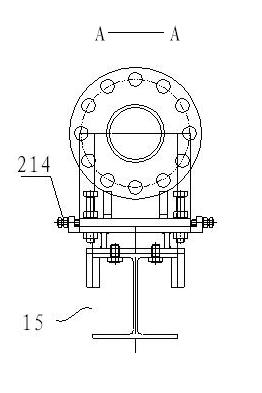

[0030] combine Figure 1 to Figure 7 As shown, the pipeline hydraulic testing device of the present invention includes a testing machine body 1, and the bed 1 is provided with a hydraulic thrust power unit, a pipeline connector 3, a composite seal 31, and a bracket 14, wherein: the universally adjustable base 21 It is detachably installed on the bed 1, which includes a U-shaped top plate, a vertical adjustment mechanism 211, and a horizontal adjustment structure 214. The bottom plate of the hydraulic thrust power unit is located in the groove of the U-shaped top plate; the vertical adjustment mechanism 211 is installed vertically on the On the four corners of the bottom plate of the hydraulic thrust power unit, and between the bottom plate of the hydraulic thrust p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com