A pipeline blocking device

A technology for pipes and sealing gaskets, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc., and can solve the problem of reduced axial strength of pipes, immature technology and equipment for external reinforcement repairs, and adjustment of preload Difficulties and other problems, to achieve the effect of safe and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

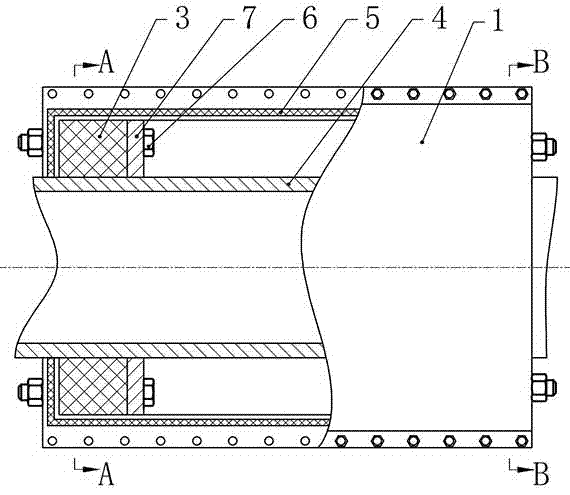

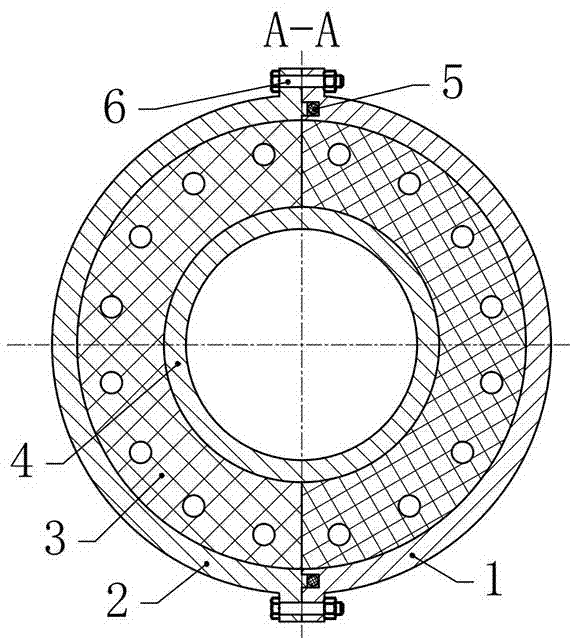

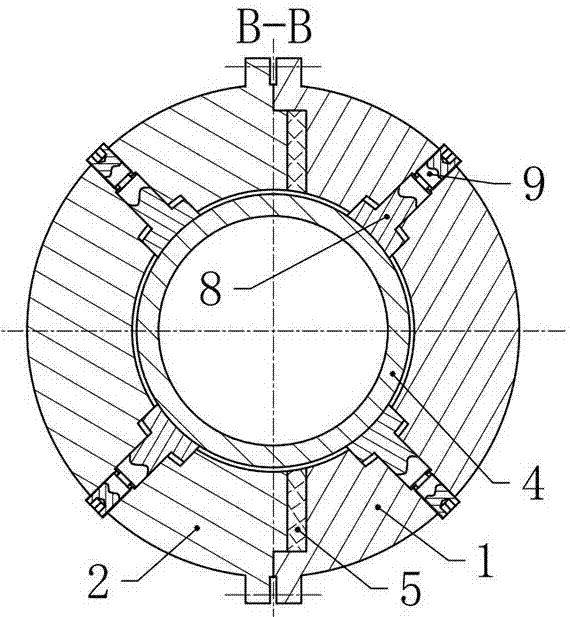

[0030] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0031] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 shown.

[0032] The upper casing 2 and the lower casing 1 are hollow semi-cylindrical bodies, the upper casing 2 and the lower casing 1 are connected by bolts 6, and the lower casing 1 is provided with a rectangular groove at the connection part with the upper casing 2, so that A sealing gasket 5 is arranged in the rectangular groove. The upper casing 2 is provided with a boss at the part combined with the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com