Pre-water filling steel tube hydraulic test method and special-purpose equipment thereof

A technology of hydrostatic testing and special equipment, which is applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problems of low efficiency and high production cost, and reduce the occupied area , save costs, and improve the effect of suppressing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

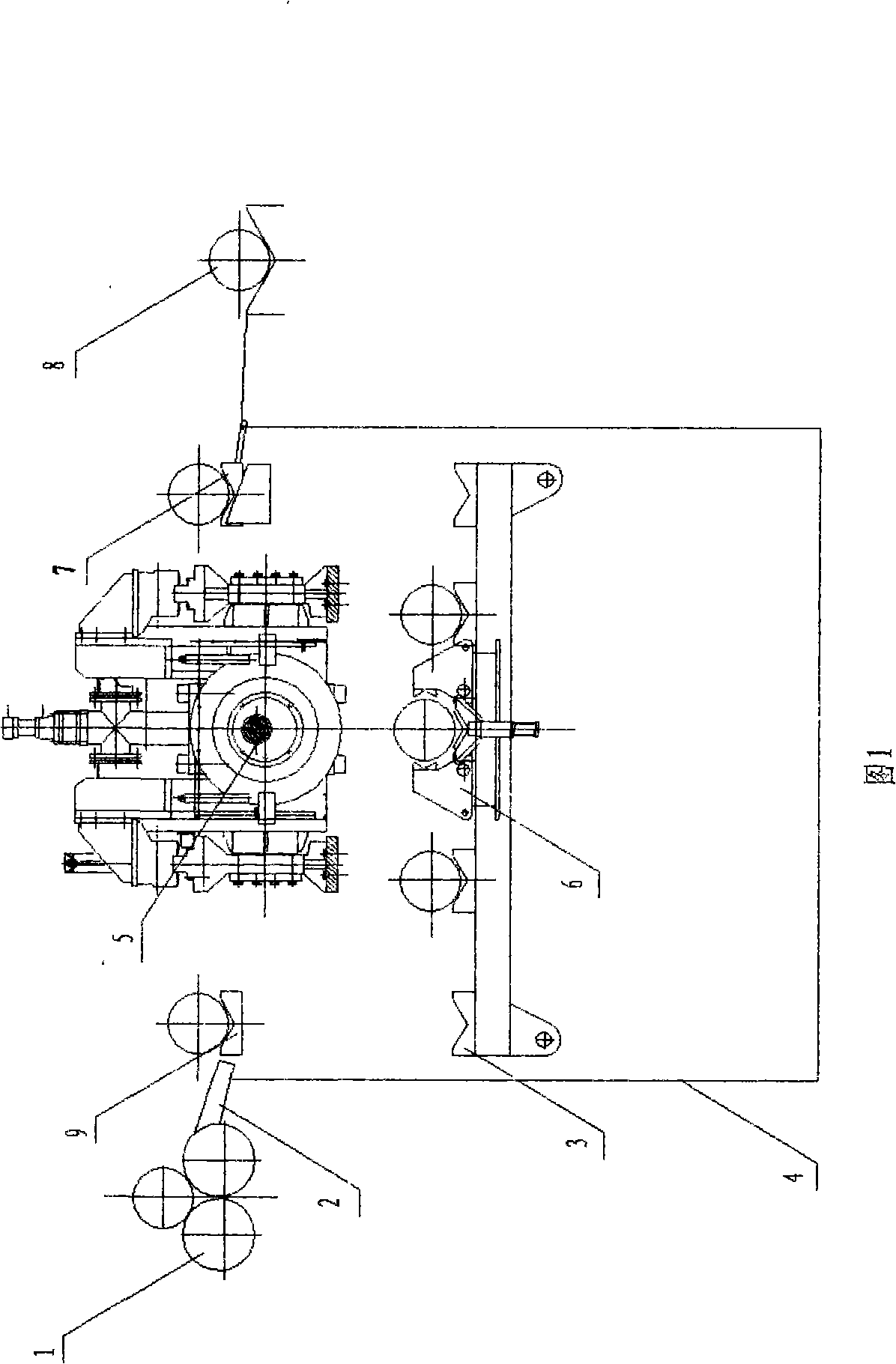

[0019] Embodiment 1, referring to Fig. 3, is processed into a medium box 4, the medium is generally an anti-rust floating liquid, a pipe transfer mechanism 3 is installed in the medium box 4, and a clamping mechanism 6 is installed on the pipette mechanism 3, and the clamping mechanism 6 It can be lifted and lowered, and a hydraulic test mechanism 5 is installed above the pipe transfer mechanism 3, and a lifting mechanism 9 and a discharge mechanism 7 are respectively installed above the two ends of the pipe transfer mechanism 3. The discharge mechanism 7 can be lifted, and the other end of the discharge mechanism 7 Install the empty water mechanism 8, the two are connected, install the feeding mechanism 2 between the lifting mechanism 9 and the rotary flushing mechanism 1, one end of the feeding mechanism 2 is connected with the rotary flushing mechanism 1, and the other end is connected with the lifting mechanism 9 .

[0020] Use the above-mentioned equipment to carry out th...

Embodiment 2

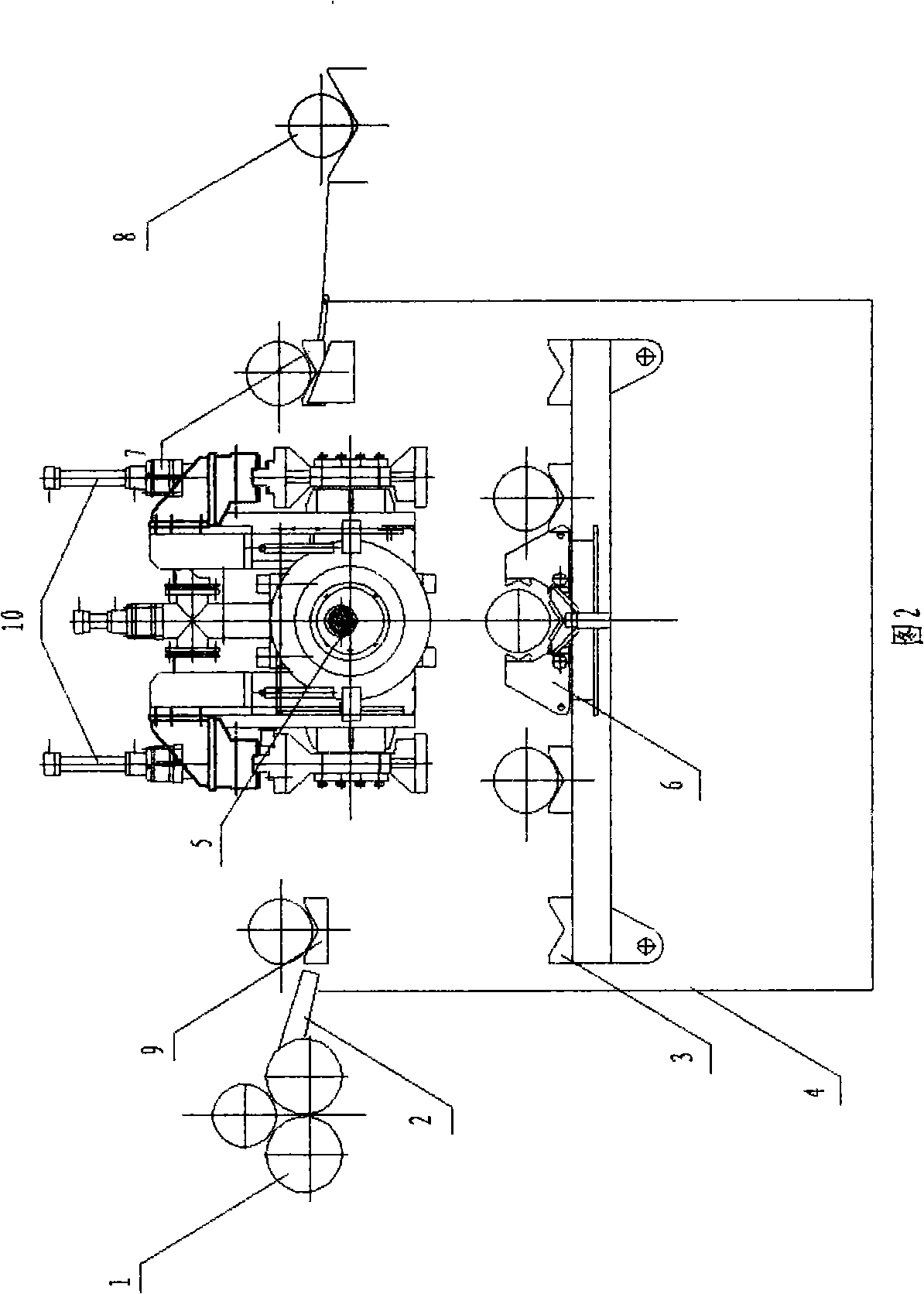

[0021] Embodiment 2, referring to Fig. 4, is the same as Embodiment 1, except that the clamping mechanism 6 does not lift up and down, and a pressure beam lifting mechanism 10 is set on the hydraulic pressure test mechanism 5, and the pressure beam lifting mechanism 10 drives the hydraulic pressure test mechanism 5. Press mechanism 5 can lift.

[0022] Using the equipment in Example 2, the specific actions of the pre-filled steel pipe hydraulic test method are as follows: first, the steel pipe is rinsed on the rotary flushing mechanism 1 to remove foreign matter on the inner surface of the steel pipe, and the action of the feeding mechanism 2 will flush the steel pipe after the flushing is completed. The steel pipe is sent to the lifting mechanism 9, and the lifting mechanism 9 descends to put the steel pipe on the pipe transfer mechanism 3. At this time, the steel pipe has been completely immersed in the hydraulic medium in the water tank 4 and filled with the hydraulic medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com