Portable active hydraulic tester and test method

A hydraulic tester, a portable technology, is applied in the testing of fluid pressure actuation systems, fluid pressure actuation devices, mechanical equipment, etc., which can solve the problems of difficult connection and expensive sensor testing, and achieve low cost, easy connection, and testing. precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

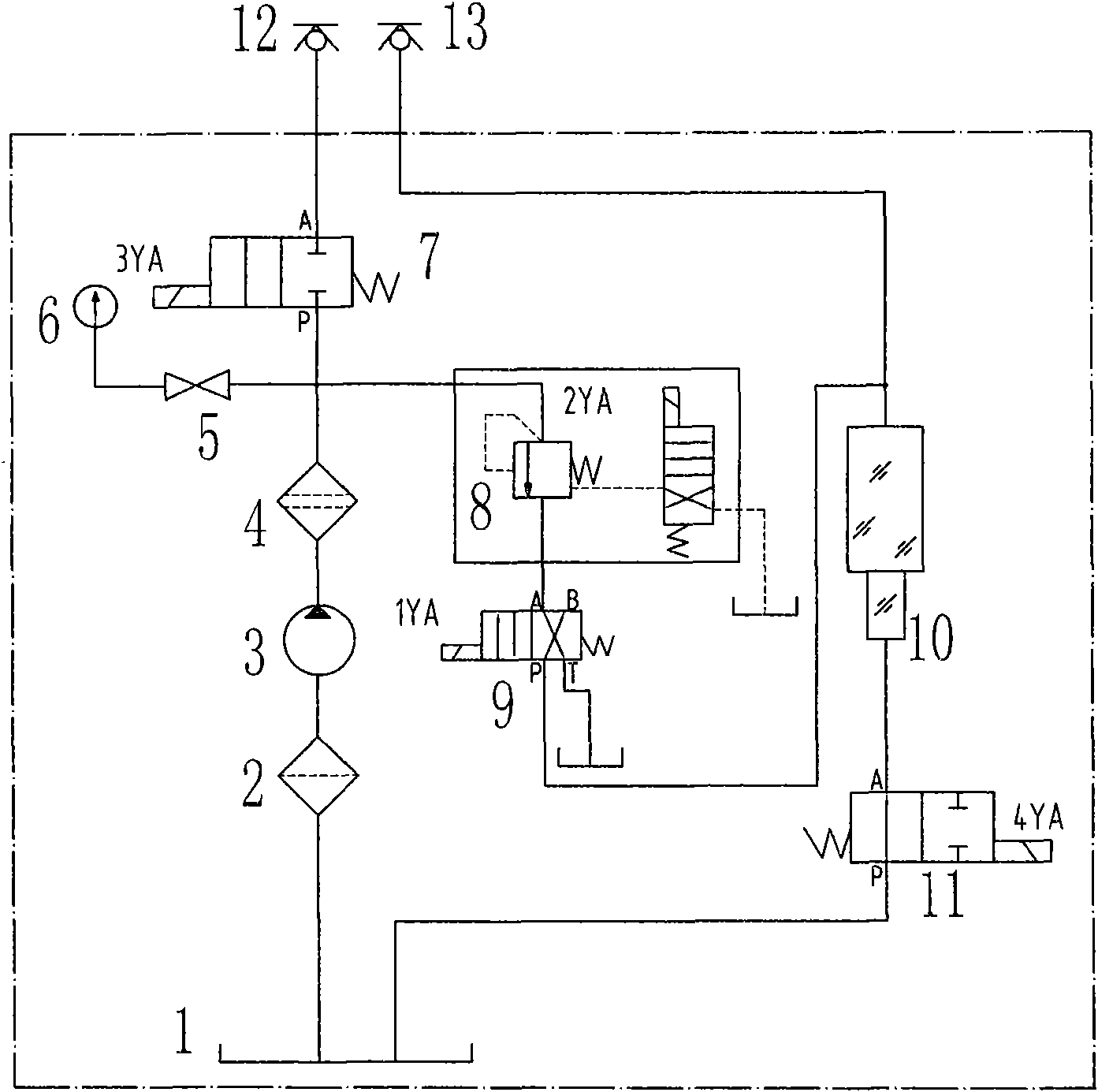

[0022] See figure 1 , a portable active hydraulic tester, which is composed of a filter, a hydraulic pump, an electromagnetic reversing valve, an electromagnetic overflow valve, and a measuring cylinder. The connection structure is: the coarse filter 2 is connected to the oil inlet of the hydraulic pump 3, and the oil outlet of the hydraulic pump 3 is connected to the inlet of the fine filter 4; the outlet of the fine filter 4 is respectively connected to the pressure gauge switch 5. The inlet connection of the normally off two-position two-way electromagnetic reversing valve 7 and the electromagnetic overflow valve 8; the pressure gauge switch 5 is connected with the pressure gauge 6; the normally-off two-position two-way electromagnetic reversing valve 7 is quickly The joint 12 is connected; the oil return port of the electromagnetic overflow valve 8 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com