Automatic control system for nucleonic product hydraulic pressure test using Zigbee wireless communication

A technology of automatic control system and hydraulic test, applied in wireless communication, transmission system, signal transmission system, etc., can solve the problems of insufficient standardization and accuracy of manual operation, and achieve automatic program control, easy operation, and extended data collection. the effect of the means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

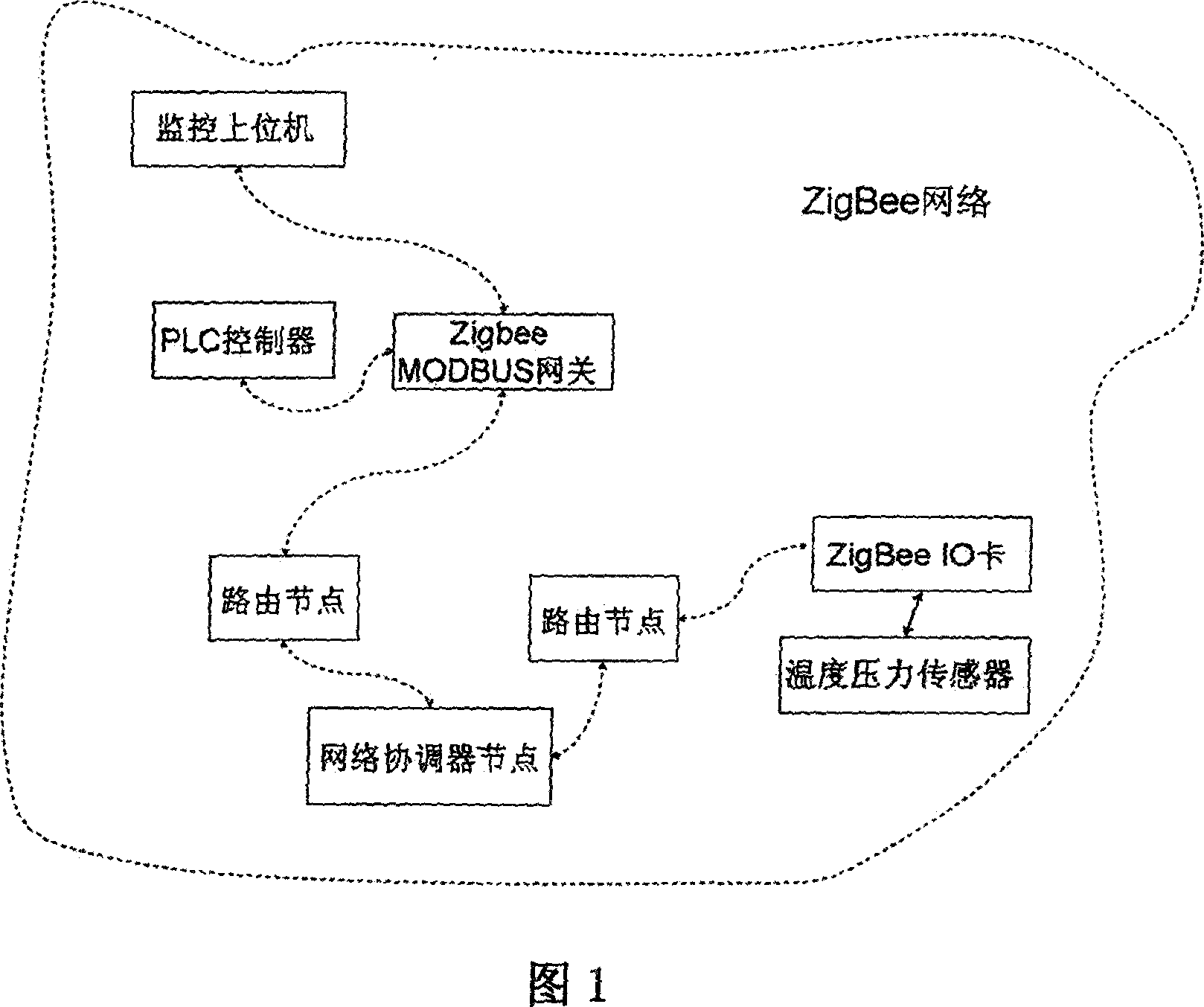

[0015] As shown in Figure 1, the terminal nodes and a small programmable controller PLC for collecting the pressure and temperature data of the hydraulic test are arranged in the place where the hydraulic test is performed. Through the network coordinator, routing nodes and ZigBee IO cards, a ZigBee wireless network is formed (the wireless network is based on the self-organizing grid topology unique to the industrial EEE 802.15.4 / Zigbee communication technology), and through the ZigBee-Modbus gateway, related The data is transmitted to the monitoring host computer and PLC control system for data recording and processing.

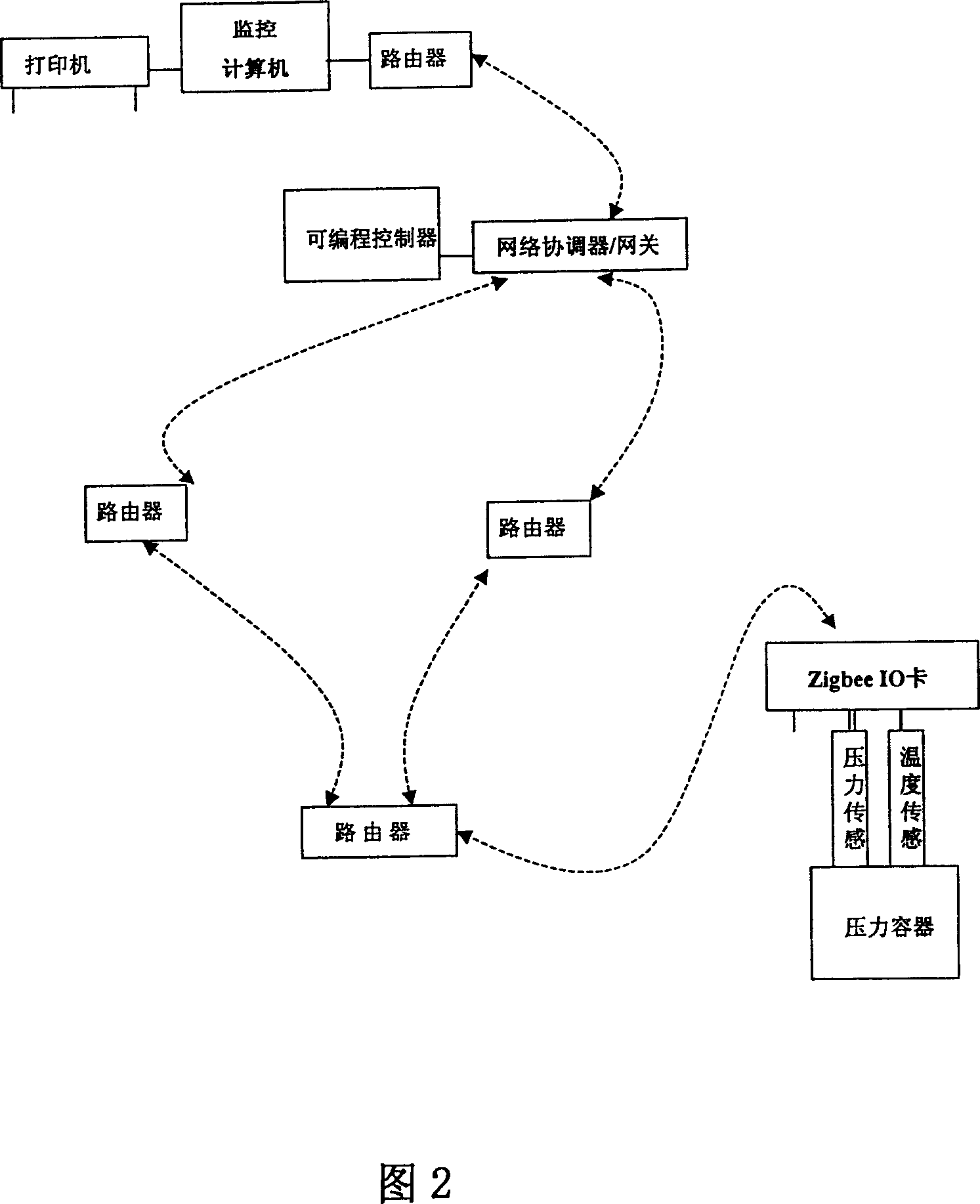

[0016] Choose a reasonable installation position for sensors such as temperature and pressure, that is, it must be able to respond sensitively to changes in pressurization, and it must also ensure the pressurization data of the entire pressure vessel, and it must be easy to install. The temperature and pressure sensor obtains the temperature and pressure sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com